Unlocking Precision: The Future of Manufacturing with CNC Turning Machines Explained

The future of manufacturing lies in embracing these sophisticated CNC turning machines, which not only cater to complex geometries but also optimize workflows and reduce operational costs. As the demand for customized solutions increases, understanding the benefits and functionalities of CNC turning machines becomes essential. This article delves into the pivotal role that these machines play in shaping modern manufacturing, exploring their advantages and the innovative possibilities they unlock for businesses aiming to stay ahead in a competitive market.

Understanding CNC Turning Machines: Key Features and Benefits

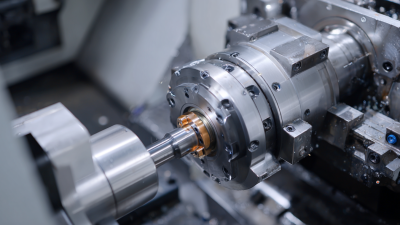

CNC turning machines have emerged as a cornerstone of modern manufacturing, offering unparalleled precision, efficiency, and versatility. By leveraging advanced technology, these machines can operate on multiple platforms, including Swiss, conventional, and multitasking setups, enabling manufacturers to tackle various machining challenges with ease. The key features of CNC turning machines include high-speed operation, automated tooling, and enhanced accuracy, making them indispensable for industries that demand high-quality components.

Tips for maximizing the benefits of CNC turning machines include regular maintenance to ensure optimal performance and investing in employee training to enhance operational efficiency. Additionally, integrating AI-driven tools can greatly boost productivity by enabling predictive analytics and real-time monitoring, which helps in maintaining the quality and consistency of the production process.

As the CNC machine market is poised for significant growth, understanding the capabilities of CNC turning technology is crucial for manufacturers aiming to stay ahead. Embracing digital transformation and continually adapting to technological advancements will empower businesses to sculpt the future of manufacturing with greater precision and innovation.

Essential Steps to Set Up Your CNC Turning Machine for Optimal Performance

Setting up a CNC turning machine for optimal performance requires a keen understanding of the essential steps involved. First and foremost, proper calibration is critical. This involves aligning the machine's axes and ensuring that the tool paths are accurately configured. By using precision measuring instruments, operators can verify that the machine's movements correlate perfectly with the programmed specifications. Regular calibration reduces the risk of errors and enhances the overall quality of the manufactured parts.

Next, selecting the right tools and materials is vital for maximizing efficiency. High-quality cutting tools should be matched to the specific materials being processed, taking into account factors such as hardness and machining properties. Additionally, employing proper cutting speeds and feeds can significantly influence the performance and longevity of the tools. By continuously monitoring these parameters, operators can adjust settings in real-time, ensuring that the machine operates at its best and minimizes downtime associated with tool wear and replacement.

Unlocking Precision: CNC Turning Machines Performance Analysis

This chart illustrates the efficiency and production quality improvements with the implementation of CNC turning machines over time.

Best Practices for Maintaining Your CNC Turning Equipment

Maintaining CNC turning machines is crucial for ensuring their longevity and precision in manufacturing. Regular upkeep not only enhances the performance of these machines but also minimizes downtime due to unexpected failures. One of the best practices is to implement a routine inspection schedule. Checking for wear and tear on components such as the spindle, turret, and tools can prevent minor issues from escalating into major problems. Additionally, always keep the machine clean and free of debris to avoid interference with operations.

Lubrication is another vital aspect of CNC turning equipment maintenance. Proper lubrication reduces friction and heat generation, which are common causes of premature wear. Using the right type of lubricant, as specified by the manufacturer, is essential. Furthermore, users should pay attention to coolant levels and quality, ensuring they are adequate to maintain optimal operating conditions. By adhering to these best practices, manufacturers can unlock the full potential of their CNC turning machines, achieving greater efficiency and higher precision in their production processes.

Unlocking Precision: The Future of Manufacturing with CNC Turning Machines Explained - Best Practices for Maintaining Your CNC Turning Equipment

| Maintenance Practice | Frequency | Recommended Tools | Expected Outcome |

|---|---|---|---|

| Lubrication of moving parts | Weekly | Oil and grease | Reduced friction and wear |

| Checking and cleaning filters | Monthly | Compressed air | Improved airflow and efficiency |

| Calibrating machine settings | Quarterly | Calibration tools | Enhanced accuracy and precision |

| Inspecting belts and drive systems | Biannually | Inspection tools | Prevention of unexpected breakdowns |

| Full machine inspection | Annually | Complete toolkit | Assured operational reliability |

Innovative Applications of CNC Turning in Modern Manufacturing

CNC turning machines are revolutionizing modern manufacturing by offering precision and efficiency across various applications. From automotive parts to medical devices, the versatility of CNC turning technology allows manufacturers to create complex geometries with unparalleled accuracy. One innovative application involves producing intricate components for aerospace engineering, where the demands for precision and reliability are paramount. The ability of CNC turning machines to work with a wide range of materials, including metals and plastics, further enhances their utility in specialized industries.

Tips for optimizing CNC turning include investing in high-quality tooling that can withstand wear and tear, thereby improving the lifespan and performance of the machinery. Regular maintenance schedules should also be established to ensure machines are operating at peak efficiency. Additionally, utilizing advanced software for programming can streamline the production process, minimizing errors and reducing cycle times.

Another noteworthy application of CNC turning is in the production of custom prototypes. Manufacturers can quickly iterate designs and produce small batches, allowing for rapid feedback and development. This adaptability not only shortens time to market but also helps companies stay competitive in a fast-paced environment. Embracing these innovative applications will undoubtedly unlock new potentials within the manufacturing landscape.

Future Trends in CNC Technology: A Glimpse into Smart Manufacturing Solutions

The landscape of CNC technology is rapidly evolving, ushering in a new era of

smart manufacturing solutions. With the integration of

digital manufacturing technologies, productivity across various industries has experienced remarkable improvements. This shift

not only enhances operational efficiency but also paves the way for more sophisticated and automated processes,

allowing manufacturers to meet the increasing demands of the market with precision and speed.

At the forefront of these advancements is the upcoming showcase at EMO 2025, where innovations in metrology will be

highlighted as key components of future manufacturing strategies. This event reflects the industry’s commitment to

"Innovate Manufacturing," embodying the drive to harness cutting-edge technologies that enhance manufacturing

capabilities. As CNC turning machines and associated technologies continue to develop, the focus on precision and smart manufacturing will redefine the standards and practices

within the sector, promising a transformative impact on how products are designed and produced.

Related Posts

-

What is the Best CNC Turning Machine for Your Manufacturing Needs?

-

Discover World-Class Manufacturing: Elevate Your Production with the Best CNC Turning Machine from China

-

Revolutionizing Precision: Exploring the Impact of CNC Turning Machines on Modern Manufacturing

-

Ultimate Guide to Selecting the Best CNC Lathe Machine for Your Business Needs

-

Navigating Global Trade: Understanding Import and Export Certifications for the Best Types of CNC Machines

-

Exploring the Future of Precision Manufacturing: Best CNC Lathe and Milling Machines for Global Buyers