Discover the Unique Features of Best CNC Lathe Machines and How to Choose the Right One

In the rapidly evolving landscape of manufacturing, the CNC lathe machine has emerged as a cornerstone of precision engineering, significantly enhancing productivity and accuracy. According to a recent report by MarketsandMarkets, the global CNC machine market is projected to reach $117.72 billion by 2025, with a significant contribution from lathe machines, driven by advancements in automation and demand for intricate components. With their ability to automate complex machining tasks and improve operational efficiency, CNC lathe machines are favored across various industries, including aerospace, automotive, and medical device manufacturing. However, selecting the right CNC lathe machine can be a daunting task given the myriad of features and specifications available. This blog will explore the unique features of the best CNC lathe machines and provide insights on how to make an informed choice tailored to your specific machining needs.

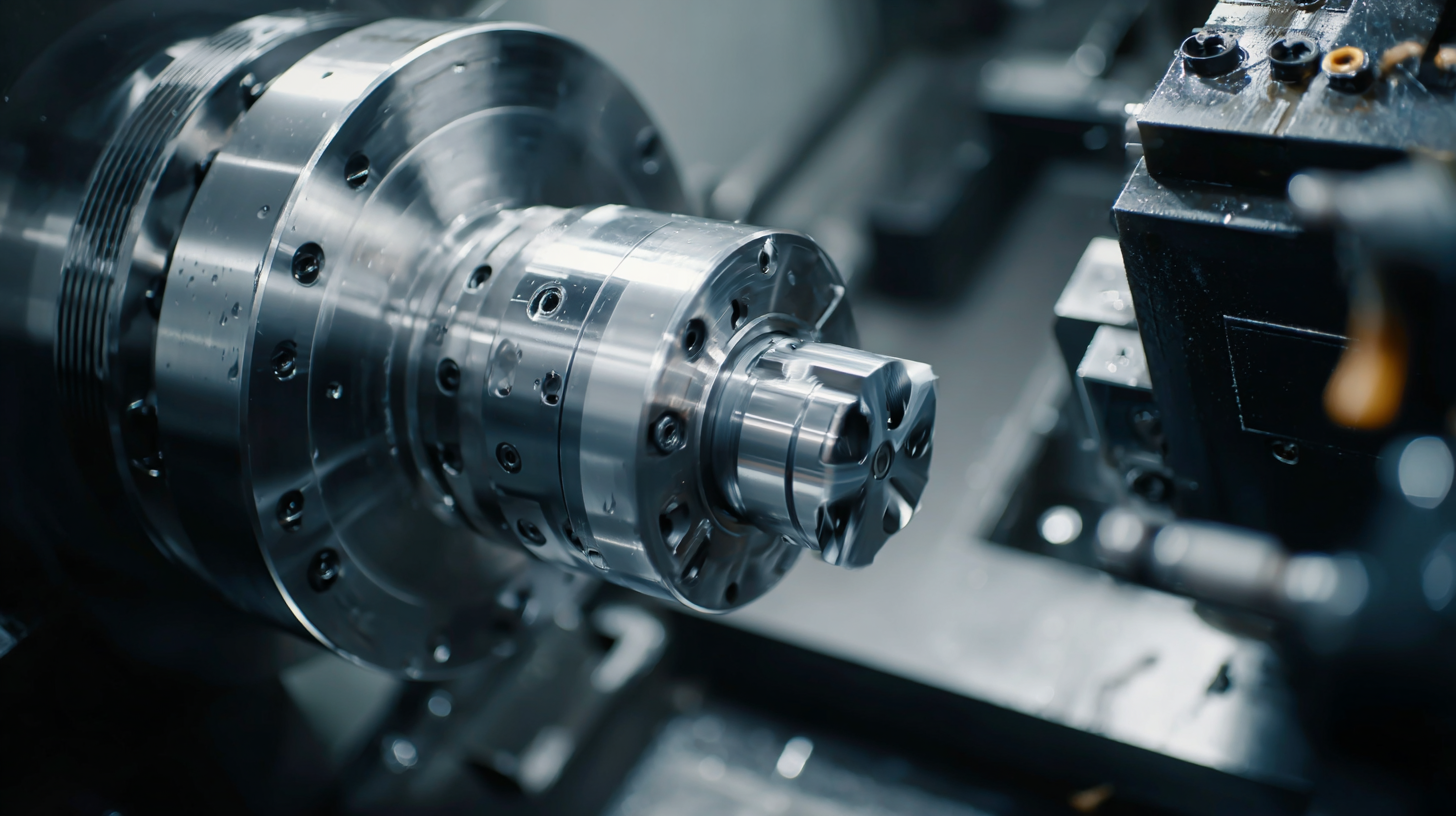

Understanding the Key Characteristics of CNC Lathe Machines in Today's Manufacturing Landscape

The manufacturing landscape today is increasingly defined by the advanced capabilities of CNC lathe machines, which are integral to precision machining and mass production. Understanding the key characteristics of these machines is essential for manufacturers looking to remain competitive. The best CNC lathes offer features such as automated tool changing, high-speed processing, and enhanced accuracy, making them suitable for a diverse range of materials. Their ability to program complex shapes allows for intricate designs that meet modern production specifications.

As the CNC lathe market is poised for significant growth, with projections estimating a rise from $25.01 billion in 2018 to $57.54 billion by 2032, businesses must make informed choices. Factors like machine size, control system sophistication, and customization options play a crucial role in selecting the right lathe for specific applications. Additionally, understanding the ongoing trends in metal processing machinery can help manufacturers invest wisely, ensuring they leverage the latest technologies to drive efficiency and innovation in their operations.

Comparative Analysis of Popular CNC Lathe Machine Brands and Their Unique Features

When choosing a CNC lathe machine, it's essential to understand the unique features offered by various brands in the market. Each manufacturer brings its innovation, targeting different needs ranging from amateur workshops to industrial applications. For instance, some machines might excel in precision and speed, while others prioritize ease of use and maintenance. Analyzing these distinctions can help you identify the right machine tailored to your specific projects and operational demands.

**Tips:** Look for machines with advanced control systems to enhance precision, and consider those with robust support for materials like Inconel 713C if working with tougher materials is a priority. Also, pay attention to user reviews and real-world performance metrics, as these can provide insight into reliability and quality.

As the CNC machine market continues to grow significantly, with projections showing a rise from $101.22 billion in 2025 to $195.59 billion by 2032, it becomes increasingly crucial to stay informed on the best options available. The comparative analysis of different brands and their offerings can empower you in making an informed decision to invest wisely in the best CNC lathe machine for your needs.

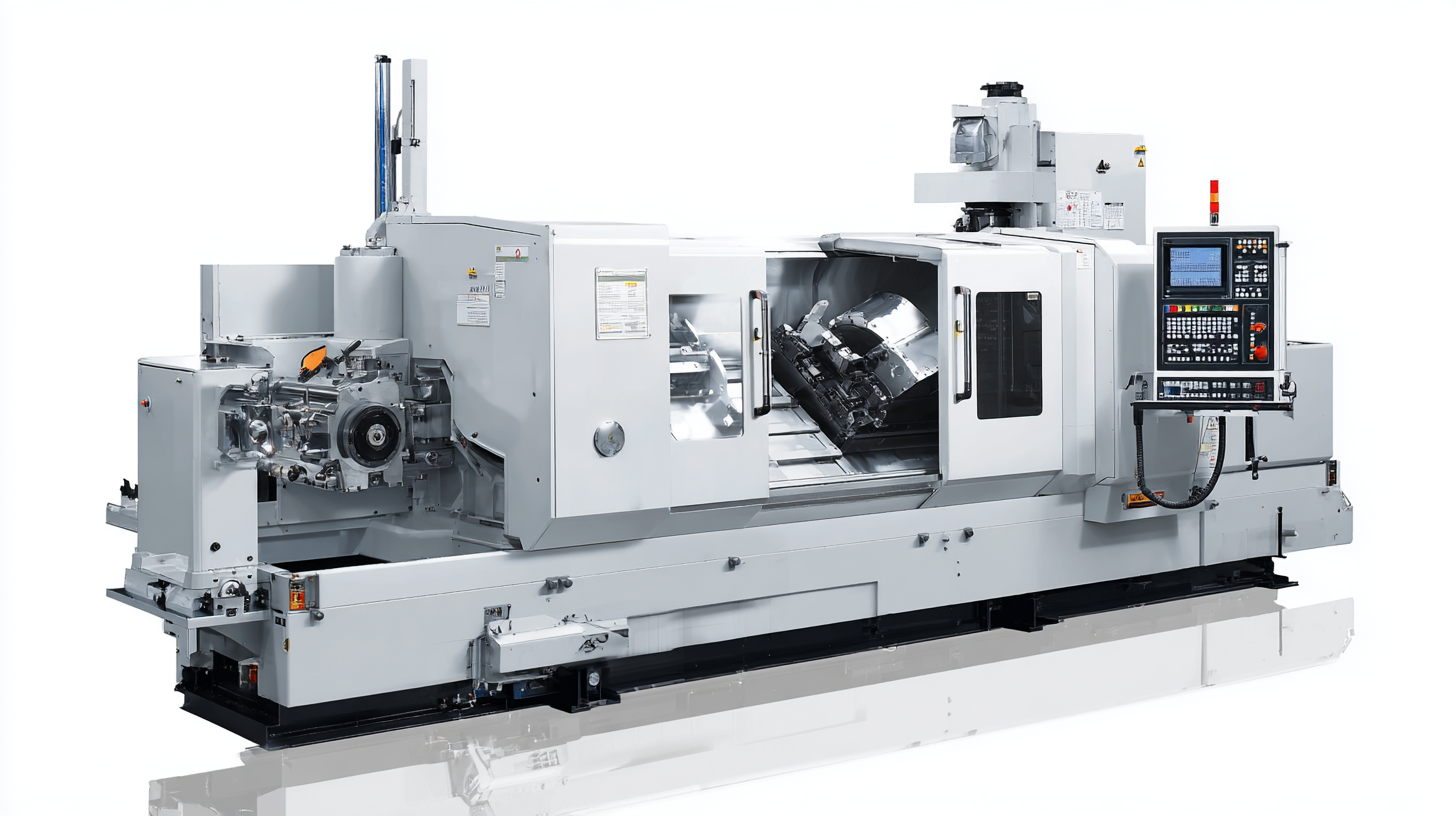

Essential Factors to Consider When Choosing the Right CNC Lathe for Your Operations

When selecting the right CNC lathe for your operations, there are several essential factors to consider that can significantly impact your production efficiency and product quality. One of the most critical aspects is the machine's size and capacity. Ensure that the CNC lathe can handle the maximum workpiece size you require, as well as the types of materials you will be working with. This will help avoid constraints in your machining processes.

Another crucial factor is the machine's precision and repeatability. Look for CNC lathes that offer high accuracy to meet your tolerances and specifications. Investing in a lathe with advanced control systems can enhance the precision of your operations, leading to superior product quality.

**Tip:** Always evaluate the power and torque of the CNC lathe, as these specifications will affect the machining speed and efficiency.

Lastly, consider the software compatibility and ease of use. A user-friendly interface can significantly reduce the learning curve and increase productivity. **Tip:** It’s beneficial to choose a model with compatible software that allows for easy integration with your existing systems.

Discover the Unique Features of Best CNC Lathe Machines and How to Choose the Right One

| Feature | Description | Importance | Considerations |

|---|---|---|---|

| Spindle Speed | Maximum rotational speed of the spindle | High importance for precision work | Choose based on materials being machined |

| Tool Capacity | Number of tools that can be stored | Medium importance for production efficiency | Select based on complexity of parts |

| Control System | Type of software used to operate the lathe | High importance for usability and programming | Familiarity with software is crucial |

| Accuracy | Precision in machining parts | Critical for quality assurance | Check manufacturer specifications |

| Bed Length | The length of the lathe bed for larger parts | Deciding factor for part size capabilities | Evaluate needs for larger projects |

Evaluating CNC Lathe Alternatives: Cost-Effectiveness vs. Performance Metrics

When evaluating CNC lathe alternatives, the balance between cost-effectiveness and performance metrics becomes crucial for manufacturers seeking to optimize their production processes. A recent study highlights that machining cost evaluation per part incorporates setup costs, tool usage costs—which are influenced by cutting parameters—and the amortization of machinery. Notably, as China's manufacturing sector constitutes more than half of the nation's total energy demand, careful consideration of these costs is essential, especially in metal processing, where efficiency can directly influence profitability.

Furthermore, industry professionals are encouraged to implement Key Performance Indicators (KPIs) for production efficiency assessment. A holistic approach to performance measures can enhance decision-making in selecting CNC lathe machines tailored to specific operational needs. For instance, utilizing a novel FMECA method can provide insights into system reliability and potential operational failings, thereby promoting better investment choices in CNC technology. As the industry evolves, leveraging such analytical frameworks and performance metrics will be pivotal in navigating the complexities of cost vs. performance in CNC lathe operations.

Exploring Advanced Technologies in CNC Lathes: Integration and Automation Trends

The CNC lathe market is poised for significant growth, driven by advancements in integration and automation technologies. The global CNC machine market is expected to expand from $101.22 billion in 2025 to an impressive $195.59 billion by 2032, reflecting a robust compound annual growth rate (CAGR) of 9.9%. This surge indicates that manufacturers are increasingly adopting CNC lathes to enhance precision and efficiency in their operations.

As industries seek to optimize their manufacturing processes, the integration of advanced technologies is becoming a key focus. Automation trends in CNC lathes are not only streamlining operations but also enhancing machine capabilities. For instance, the CNC controller market is projected to grow steadily from $33.66 million in 2025 to $22.87 million by 2033, illustrating the rising demand for more versatile and intelligent CNC systems. These innovations are essential for companies striving to stay competitive in a rapidly evolving market where precision and productivity are paramount.