Top 10 CNC Milling Machines for Precision Manufacturing in 2023

In the fast-evolving landscape of precision manufacturing, CNC milling machines stand out as essential tools driving innovation and efficiency. As we explore the top 10 CNC milling machines of 2023, understanding their capabilities and advancements becomes imperative for manufacturers aiming to maintain competitive advantages. Renowned industry expert Dr. James Harlow, a leading figure in CNC technology, aptly stated, "The evolution of CNC milling machines continues to redefine the boundaries of precision and productivity, enabling us to craft components with unmatched accuracy."

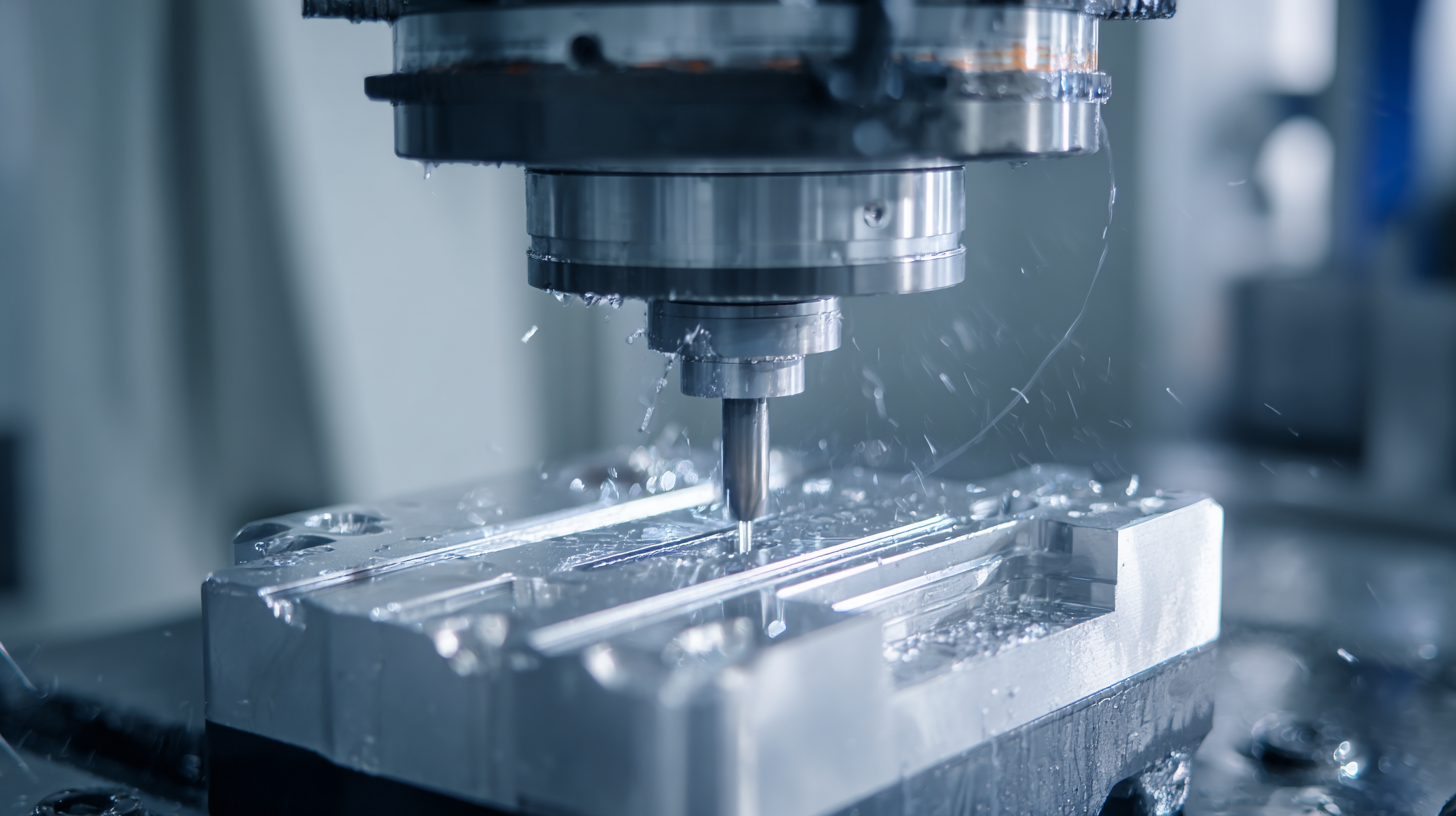

The significance of CNC milling machines cannot be overstated; they provide unparalleled precision, allowing manufacturers to produce intricate designs with minimal tolerance for error. In 2023, the latest models are equipped with advanced features such as smart technology integration, enhanced spindle performance, and intuitive interface designs that simplify operations. As we delve into the specifics of each machine, it's crucial to understand how these advancements contribute to improving manufacturing processes and outcomes.

As we embark on this exploration, the goal is to illuminate the top contenders in the CNC milling machine market. By highlighting their strengths and innovations, we aim to provide manufacturers with valuable insights that can guide their decisions in selecting the right machinery for their needs. Whether you are a seasoned professional or just entering the field, this overview will illuminate the transformative potential of CNC milling machines in today’s manufacturing environment.

Overview of CNC Milling Machines and Their Importance in Precision Manufacturing

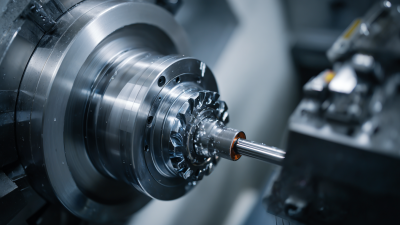

CNC milling machines have become indispensable in the realm of precision manufacturing, playing a crucial role in various industries, from aerospace to automotive. These machines utilize computer numerical control to automate the cutting processes, allowing for unprecedented accuracy and complexity in shaping materials. The integration of digital manufacturing technologies has revolutionized productivity, enabling manufacturers to produce high-quality components with tighter tolerances and reduced cycle times. As a result, businesses are better equipped to meet the demands of an increasingly competitive market.

CNC milling machines have become indispensable in the realm of precision manufacturing, playing a crucial role in various industries, from aerospace to automotive. These machines utilize computer numerical control to automate the cutting processes, allowing for unprecedented accuracy and complexity in shaping materials. The integration of digital manufacturing technologies has revolutionized productivity, enabling manufacturers to produce high-quality components with tighter tolerances and reduced cycle times. As a result, businesses are better equipped to meet the demands of an increasingly competitive market.

The importance of CNC milling machines extends beyond mere efficiency; they are fundamental to maintaining high standards of quality and repeatability in production. With advancements in technology, such as multi-objective optimization design and simulation techniques, manufacturers can optimize machine performance and enhance their output capabilities. This evolution supports the growing trend towards smart manufacturing, where connectivity and data-driven decision-making are paramount. As the CNC machine market continues to expand, it is clear that these machines are at the forefront of modern manufacturing practices, enabling precision and productivity in equal measure.

Key Features to Consider When Choosing a CNC Milling Machine

When selecting a CNC milling machine for precision manufacturing, there are several key features to consider. First and foremost, accuracy and repeatability are crucial; the machine should deliver consistent precision in its operations. Look for specifications that indicate a high degree of tolerance and minimal backlash, which ensures that the final products meet strict quality standards. Additionally, the versatility of the machine plays an important role. A CNC mill that can handle a variety of materials—from metals to plastics—expands its usability across different projects and industries.

Another significant factor to consider is the machine's ease of use. Intuitive software interfaces and user-friendly controls can greatly enhance productivity, especially for those who are new to CNC operations. Features like manual override and simplified setup processes can reduce learning curves and downtime. Moreover, the ability to integrate with other technologies, such as AI-driven analytics for smart operations, allows for continuous improvement in manufacturing efficiency, making these advanced machines even more appealing for modern workshops.

Top 10 CNC Milling Machines for Precision Manufacturing in 2023

Top 10 CNC Milling Machines of 2023: Detailed Review and Comparisons

In 2023, the landscape of CNC milling machines continues to evolve, presenting manufacturers with a plethora of options to choose from. Our detailed review highlights the top ten CNC milling machines that stand out due to their precision, reliability, and innovative features. Each machine has been assessed based on its performance metrics, ease of use, and the versatility it offers, allowing manufacturers to find the perfect fit for their specific production needs.

The comparisons among these machines not only showcase their distinct capabilities but also provide insights into how they can optimize various manufacturing processes. From compact models suitable for small workshops to robust, high-capacity machines designed for large-scale operations, our review emphasizes the importance of choosing a CNC milling machine tailored to individual project requirements. By examining the unique features of each model, including spindle speed, tool capacity, and software compatibility, manufacturers can make informed decisions that enhance productivity and precision in their operations.

Maintenance Tips for Ensuring Longevity of CNC Milling Machines

Regular maintenance is crucial for ensuring the longevity and optimal performance of CNC milling machines. According to the American Society of Mechanical Engineers (ASME), routine maintenance can extend machine life by up to 30%. Key maintenance practices include regular lubrication, cleaning of machine components, and periodic inspections. Proper lubrication minimizes wear and tear on moving parts, which can significantly reduce operational downtime and repair costs. It’s recommended to use high-quality lubricants that meet specific machine manufacturer guidelines to enhance efficiency.

Additionally, maintaining a clean work environment greatly contributes to the longevity of CNC machines. The National Institute of Standards and Technology (NIST) reports that dust and debris can lead to costly repairs, affecting precision and productivity. Implementing a regular cleaning schedule and using air filtration systems can mitigate these risks. Furthermore, ensuring that all software is updated and that operational parameters are correctly set according to the manufacturer's specifications can not only improve precision but also prevent potential failures. By adhering to these best practices, manufacturers can achieve optimal performance and achieve a greater return on investment over the machine's lifespan.

Top 10 CNC Milling Machines for Precision Manufacturing in 2023 - Maintenance Tips for Ensuring Longevity of CNC Milling Machines

| Model | Max Speed (RPM) | Spindle Power (kW) | Working Envelope (mm) | Weight (kg) | Maintenance Frequency (Months) |

|---|---|---|---|---|---|

| Model A | 12000 | 15 | 600 x 400 x 400 | 800 | 6 |

| Model B | 10000 | 10 | 800 x 500 x 500 | 950 | 8 |

| Model C | 15000 | 20 | 1000 x 600 x 600 | 1200 | 5 |

| Model D | 9000 | 8 | 700 x 400 x 400 | 700 | 12 |

| Model E | 11000 | 12 | 900 x 700 x 700 | 1050 | 7 |

| Model F | 13000 | 18 | 1000 x 800 x 800 | 1500 | 4 |

| Model G | 14000 | 24 | 1200 x 800 x 800 | 1600 | 3 |

| Model H | 13000 | 16 | 1100 x 900 x 900 | 1400 | 6 |

| Model I | 8500 | 9 | 500 x 500 x 400 | 600 | 10 |

| Model J | 9000 | 11 | 600 x 600 x 600 | 920 | 9 |

Future Trends in CNC Milling Technology and Their Impact on Precision Manufacturing

As we look into the future of CNC milling technology, several trends are poised to revolutionize precision manufacturing. One of the most significant advancements is the integration of artificial intelligence (AI) and machine learning into CNC systems. This technology enables machines to optimize cutting paths, predict tool wear, and even adjust to changing materials or environmental conditions in real-time, leading to enhanced accuracy and reduced downtime. The result is a more efficient manufacturing process that not only improves productivity but also minimizes waste.

Another emerging trend is the rise of additive manufacturing techniques alongside traditional CNC milling. The combination of these technologies allows manufacturers to create complex geometries that were previously impossible with conventional milling. This hybrid approach enables greater design flexibility and the potential to produce lightweight components that maintain structural integrity. Moreover, advancements in software for simulation and analytics are enhancing the ability to plan and execute machining operations with unparalleled precision, paving the way for the next generation of precision manufacturing.

Related Posts

-

Exploring CNC Milling Machine Innovations at the 2025 China Import and Export Fair

-

Innovative Trends for Best CNC Machine Milling Machine in 2025 Shaping the Future of Manufacturing

-

Revolutionizing Precision with CNC Metal Milling Machines for Modern Manufacturing

-

Unveiling the Specifications: The Ultimate Guide to the Best CNC Lathe Machine for Global Buyers

-

Top Strategies for Choosing the Best CNC Milling Machine for Your Business Needs

-

Discover How Top Chinese Factories Redefine Excellence in Precision CNC Milling Machines