Discover How Top Chinese Factories Redefine Excellence in Precision CNC Milling Machines

The landscape of manufacturing is undergoing a transformative shift, particularly in the realm of precision CNC milling machines, which have become pivotal in ensuring high accuracy and efficiency across various industries.

According to a recent market analysis report from Mordor Intelligence, the global CNC milling machine market is projected to reach $100 billion by 2025, with a compound annual growth rate (CAGR) of 5.2%.

This growth is driven largely by the increasing demand for precision-engineered parts in sectors such as aerospace, automotive, and electronics.

Chinese factories are at the forefront of this revolution, leveraging advanced technologies and innovative practices to redefine excellence in precision CNC milling.

By streamlining production processes and enhancing machine capabilities, these leading manufacturers are setting new benchmarks in quality and reliability, shaping the future of precision machining worldwide.

Understanding the Fundamentals of CNC Milling Machines in Modern Manufacturing

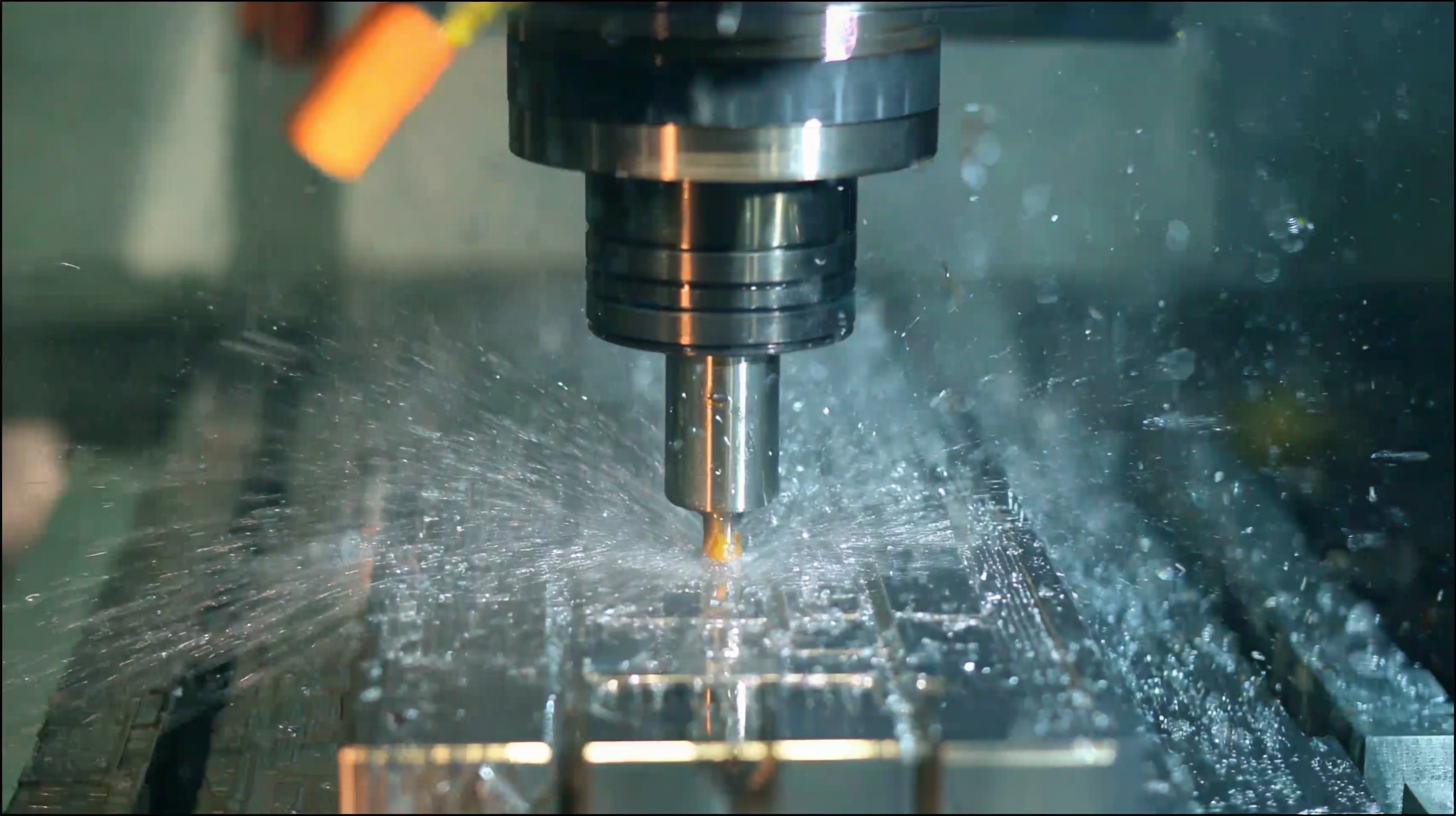

As we delve into the fundamentals of CNC milling machines in modern manufacturing, it becomes evident that precision and efficiency are paramount. Recent advancements in technology, particularly the integration of AI into CNC machining processes, are redefining operational excellence across industries. For instance, studies indicate that AI implementation in machining can enhance productivity by up to 30%, allowing for faster programming and reduced cycle times. This transformation is crucial as manufacturers aim to meet the increasing demand for complex geometries and precise finishes, especially in sectors such as aerospace and automotive.

Additionally, an understanding of process damping in milling operations has garnered significant attention within the manufacturing community. Despite decades of research, this phenomenon continues to influence machining effectiveness, with new methodologies enabling machinists to better control vibrations during the milling process. Such innovations not only improve the quality of output but also extend the lifespan of cutting tools, thereby reducing operational costs. As CNC technology evolves, the focus on training and educating the next generation of machinists is equally essential, ensuring they are equipped to excel in a landscape increasingly driven by modernization and advanced manufacturing solutions.

Discover How Top Chinese Factories Redefine Excellence in Precision CNC Milling Machines

| Parameter | Value | Unit |

|---|---|---|

| Max Spindle Speed | 12000 | RPM |

| Feed Rate | 2000 | mm/min |

| Max Cutting Depth | 5 | mm |

| Working Area (X-Y-Z) | 1000 x 600 x 500 | mm |

| Tool Change Time | 2.5 | seconds |

| Cooling System Type | Flood Cooling | |

| Accuracy (Positioning) | 0.01 | mm |

| Weight | 1500 | kg |

Key Factors That Elevate Chinese Factories in Precision CNC Milling

Chinese factories are increasingly recognized for redefining excellence in precision CNC milling machines, driven by key factors that contribute to their competitive edge in the global market. A significant aspect fueling this growth is the impressive trajectory of the CNC machine market itself, projected to grow substantially from USD 101.22 billion in 2025 to USD 195.59 billion by 2032. This robust demand is mirrored in the advancements within Chinese manufacturers, who are adapting quickly to both market needs and technological innovations.

In addition to market growth, the emphasis on high precision and advanced engineering materials plays a pivotal role in elevating Chinese factories. The evolution of technology, especially in CNC machining techniques, has spurred the development of specialized equipment tailored for demanding applications, such as those in the aerospace sector. With projections indicating a leap in the aerospace titanium machining market, poised to grow from USD 426.21 million in 2025 to USD 893.88 million by 2033, it’s clear that Chinese manufacturers are poised to play a crucial role. Their commitment to combining technology with high-quality manufacturing processes positions them as leaders in this rapidly evolving landscape, setting new benchmarks in the precision CNC milling industry.

Innovative Technologies Driving Efficiency in CNC Milling Operations

The landscape of CNC milling operations is undergoing a significant transformation driven by innovative technologies that enhance efficiency and precision. As manufacturers prepare for major trade events, the implementation of advanced automation and IoT-enabled equipment is crucial. In particular, the integration of artificial intelligence in CNC machining is revolutionizing how manufacturers approach production. AI-driven insights allow for optimized workflows, reducing downtime and enhancing the quality of finished products.

Furthermore, emerging trends, such as the growing use of zero point clamping systems, are indicative of a shift towards high-precision machining. This technology not only improves setup times but also increases repeatability, which is essential in competitive manufacturing environments. As we approach 2025, manufacturers that actively adopt these innovative solutions will be better positioned to meet the rising demands for precision and efficiency in their operations, marking a new era in the landscape of CNC milling.

Quality Control Measures Implemented by Leading Chinese CNC Manufacturers

In the dynamic landscape of CNC milling machines, leading Chinese manufacturers are setting new standards for quality control that are reshaping the industry. As the country experiences a surge in innovative capabilities, evidenced by advancements in automation and machine tool technology, manufacturers are employing rigorous quality control measures that ensure precision and reliability. This commitment to excellence has been propelled by the need for competitiveness in both domestic and international markets, especially under the pressures of emerging export controls.

Notably, factories are investing in smart manufacturing practices, leveraging advanced technologies like 5.5G connectivity to enhance production efficiency and maintain quality. For instance, the recent establishment of a smart manufacturing demonstration factory highlights the integration of high-tech solutions designed to monitor and improve manufacturing processes seamlessly. As a result, these initiatives not only elevate product quality but also foster an environment of continuous innovation, positioning Chinese CNC manufacturers at the forefront of the global market. This evolution in quality control reflects a broader trend towards greater sophistication and resilience in the manufacturing sector.

Case Studies: Success Stories from Top Precision CNC Milling Facilities in China

In the rapidly evolving landscape of manufacturing, top precision CNC milling facilities in China have emerged as beacons of excellence, showcasing innovative practices and advanced technologies. A notable case study can be found in companies like HUAWEI, which has integrated state-of-the-art CNC milling machines into its production lines. According to a recent report by Freedonia Group, the CNC machine market in China is expected to grow at an annual rate of 7.5%, reflecting the increasing demand for precision and efficiency. This growth can be attributed to the relentless pursuit of quality and precision among leading manufacturers.

Moreover, leading factories emphasize the importance of a skilled workforce adept in operating sophisticated machinery. Training programs and partnerships with technical schools have become fundamental to maintaining high production standards. For instance, facilities utilizing advanced robotics paired with CNC milling machines report a 30% increase in efficiency and a significant decrease in production errors.

Tip: Investing in continuous employee training and adopting the latest technologies can greatly enhance productivity and product quality. Additionally, implementing regular maintenance schedules for CNC equipment can prevent downtime and ensure optimal performance. Another strategy is the utilization of quality control software, which can monitor the production process in real-time, helping to identify issues before they escalate.