Solutions for Selecting the Best VMC Milling Machine for Your Manufacturing Needs

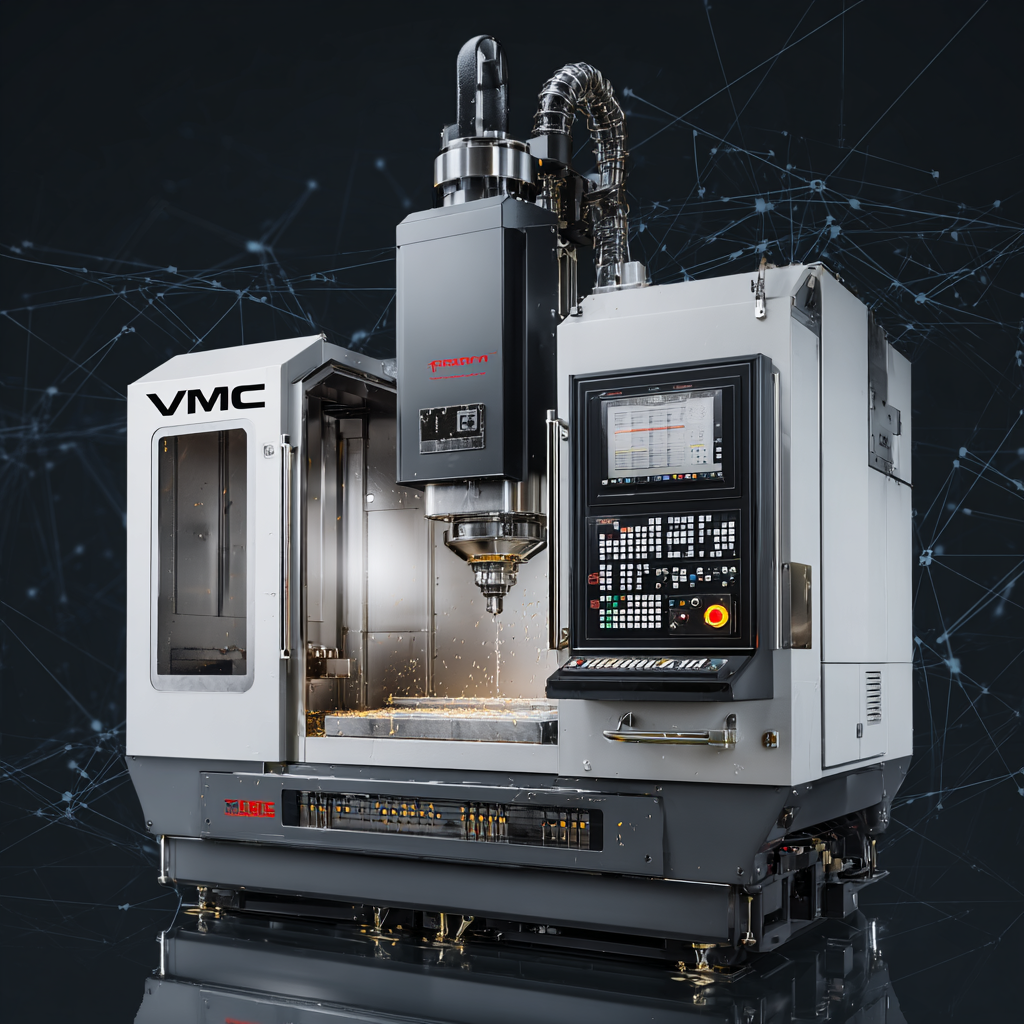

In the increasingly competitive landscape of modern manufacturing, selecting the right VMC milling machine is crucial for achieving operational efficiency and maintaining high production standards. According to a recent report by the Association for Manufacturing Technology, the demand for precision machining has grown by 15% over the past two years, underscoring the necessity for robust and reliable milling solutions. VMC milling machines are recognized for their versatility and precision, making them an essential tool for manufacturers looking to enhance their machining capabilities. As industries strive for greater automation and improved quality control, understanding the specifications, features, and technological advancements of VMC milling machines becomes imperative. This blog aims to guide manufacturers in navigating the complexities of VMC milling machine selection, ensuring that they align their equipment choices with their specific production needs and industry standards.

Key Considerations for Choosing the Right VMC Milling Machine for Your Business

When selecting the best Vertical Machining Center (VMC) milling machine for your manufacturing needs, there are several key considerations to take into account. Firstly, assess the specific requirements of your projects, including the types of materials you will be machining, the complexity of the designs, and the volume of production. Different VMCs come with varying spindle speeds, tool capacities, and travel distances, which can significantly impact your machining efficiency and output quality.

Another crucial factor is the machine's technological features. Modern VMCs offer advanced options such as CNC controls, automatic tool changers, and integrated probing systems that can enhance precision and reduce downtime. Investing in a VMC that incorporates these technologies could lead to greater productivity and improved accuracy in your manufacturing processes. Additionally, consider the support and training provided by the manufacturer, as well as the availability of spare parts and service options, to ensure long-term reliability and maintenance ease.

Emerging Technologies Shaping VMC Milling Machines in 2025

As we approach 2025, several emerging technologies are set to redefine the capabilities and efficiencies of VMC milling machines. One of the most significant advancements is the integration of artificial intelligence (AI) and machine learning. These technologies enable real-time data analysis and predictive maintenance, allowing manufacturers to optimize their processes and reduce downtime. By adopting machines that leverage AI, businesses can enhance their operational efficiency while ensuring consistent product quality.

Tip: When selecting a VMC milling machine, consider investing in models that offer advanced AI features. This will not only streamline your production processes but also help in making informed decisions based on machine performance analytics.

Another transformative technology on the horizon is the implementation of IoT (Internet of Things) connectivity. VMC milling machines equipped with IoT sensors can communicate with other machines and systems, providing valuable insights into operational metrics. This connectivity facilitates better inventory management, improves machine utilization, and supports smoother workflow transitions.

Another transformative technology on the horizon is the implementation of IoT (Internet of Things) connectivity. VMC milling machines equipped with IoT sensors can communicate with other machines and systems, providing valuable insights into operational metrics. This connectivity facilitates better inventory management, improves machine utilization, and supports smoother workflow transitions.

Tip: Look for VMC machines that come with IoT capabilities. This connectivity can significantly enhance your manufacturing flexibility and responsiveness to market changes, ultimately leading to increased productivity.

Understanding Different Types of VMC Machines and Their Applications

When selecting the best VMC milling machine for manufacturing needs, understanding the various types of VMC machines and their applications is crucial. Vertical Machining Centers (VMCs) come in various forms, including standard VMCs, 5-axis machines, and high-speed models, each designed for specific production requirements. For instance, 5-axis VMCs allow for complex geometries and multi-sided machining, significantly enhancing efficiency and precision in industries ranging from aerospace to medical device manufacturing. According to a recent market report, the global VMC market is projected to grow significantly over the next decade, driven by the increasing demand for automated solutions that improve production capabilities.

Furthermore, the application of VMC machines extends beyond traditional metalworking. Industries such as automotive and consumer electronics benefit from their ability to handle intricate designs and high-quality finishes. As reported, the convergence of AI technology with VMC operation is paving the way for smarter manufacturing solutions. By incorporating AI-driven analytics, manufacturers can optimize machine usage and predictive maintenance, significantly reducing downtime and operational costs. The evolution of VMC technologies alongside emerging trends in automation and AI is transforming manufacturing, making it essential for businesses to keep pace with these advancements to remain competitive.

Solutions for Selecting the Best VMC Milling Machine for Your Manufacturing Needs

| Type of VMC Machine | Applications | Control System | Spindle Speed (RPM) | Travel Range (X, Y, Z mm) | Max Weight Capacity (kg) |

|---|---|---|---|---|---|

| Standard VMC | General machining, small to medium parts | Fanuc | 8000 | 1000 x 500 x 500 | 500 |

| High-Speed VMC | Precision machining, mold making | Okuma | 24000 | 800 x 400 x 400 | 300 |

| 5-Axis VMC | Complex geometries and intricate parts | Siemens | 12000 | 600 x 600 x 600 | 400 |

| Vertical Machining Center | Vertical drilling and milling, heavy-duty work | Mitsubishi | 6000 | 1500 x 750 x 800 | 900 |

Cost-Effective Strategies for VMC Machine Procurement and Maintenance

In today's manufacturing landscape, cost-effective strategies for VMC machine procurement and maintenance are crucial for companies striving to maintain competitiveness. With the rising costs and ongoing supply chain disruptions, manufacturers must prioritize efficiency to navigate these economic pressures. Implementing predictive maintenance (PdM) can significantly enhance the reliability of VMC milling machines by anticipating potential failures before they occur. This proactive approach allows manufacturers to schedule maintenance based on actual machine performance rather than relying solely on regular intervals, reducing downtime and minimizing unexpected repair costs.

Additionally, integrating an advanced Computerized Maintenance Management System (CMMS) can streamline maintenance operations and inventory management for spare parts. By closely monitoring the health of machines and maintaining an optimal spare parts inventory, manufacturers can avoid costly delays associated with equipment failure. As manufacturers adapt to the challenges of the current economic climate, leveraging technology and strategic maintenance practices will ensure their VMC machines operate at peak efficiency, ultimately contributing to long-term sustainability and cost savings.

Cost-Effective Strategies for VMC Machine Procurement and Maintenance

This chart represents the average costs associated with different aspects of VMC milling machine procurement and maintenance over a five-year period. It highlights the importance of budgeting effectively to ensure long-term operational efficiency.

Future-Proofing Your Manufacturing Process with Innovative VMC Solutions

In an era where technological advancements accelerate at an unprecedented rate, future-proofing your manufacturing process is not just an option but a necessity. Recent reports from MarketsandMarkets indicate that the global CNC milling machine market is projected to grow from $15.96 billion in 2020 to $19.57 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.4%. Investing in innovative Vertical Machining Centers (VMCs) equipped with state-of-the-art features not only boosts productivity but also enhances the adaptability of your operations, ensuring your facility remains competitive in a rapidly evolving marketplace.

Modern VMC solutions incorporate advanced technologies such as artificial intelligence, which enables predictive maintenance and reduced downtime. A study by Technavio highlighted that the implementation of intelligent VMC machines can lead to up to a 20% increase in efficiency, largely due to reduced manual intervention and optimized machining processes. This technological integration positions manufacturers to meet fluctuating demands while maintaining high quality and efficiency standards. As the manufacturing landscape continues to evolve, selecting a VMC that incorporates these innovative solutions is paramount for enterprises aiming for long-term operational success.