Revolutionizing Precision with CNC Metal Milling Machines for Modern Manufacturing

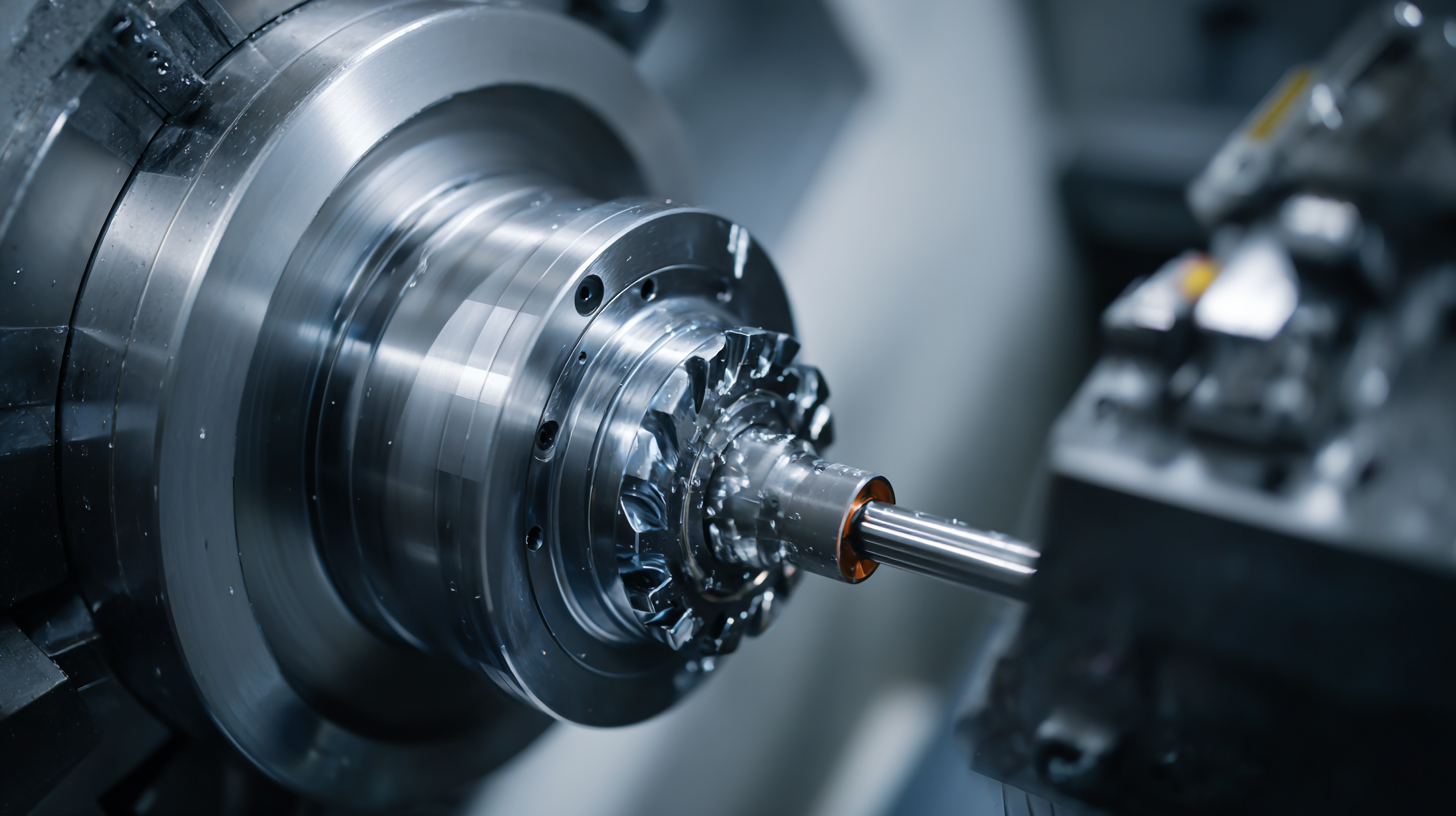

In the rapidly evolving landscape of modern manufacturing, the adoption of CNC metal milling machines is transforming precision engineering and production efficiency. According to a report by MarketsandMarkets, the CNC machine market is projected to reach $117.16 billion by 2026, with a significant portion attributed to advances in milling technologies. CNC metal milling machines, renowned for their ability to produce intricate components with high accuracy and repeatability, are increasingly utilized across various industries, including aerospace, automotive, and medical.

The integration of automation and advanced software in these machines not only optimizes production processes but also reduces lead times and material waste. As manufacturers seek to enhance their operational capabilities and adapt to the demands of a competitive market, the role of CNC metal milling machines becomes pivotal in driving innovation and efficiency in the manufacturing sector.

The Importance of CNC Metal Milling in Modern Manufacturing Efficiency

CNC metal milling machines have become a cornerstone of modern manufacturing efficiency, allowing businesses to enhance their production capabilities significantly. By automating the milling process, manufacturers can achieve high precision and repeatability in creating complex metal parts. This automation reduces human error and ensures that components are produced to exact specifications, which is crucial in industries where tolerances are tight.

Moreover, CNC metal milling not only speeds up production times but also optimizes resource utilization. The ability to program machines for various tasks means that manufacturers can switch between products with minimal downtime, thereby increasing overall output. This agility allows companies to respond swiftly to market demands while maintaining high-quality standards. As a result, investing in CNC technology not only streamlines operations but also positions manufacturers to compete effectively in an ever-evolving industrial landscape.

Key Advantages of CNC Milling Machines Over Traditional Milling

CNC ({Computer Numerical Control}) milling machines represent a significant advancement in modern manufacturing, offering notable advantages over traditional milling methods. One of the primary benefits is precision. CNC machines can produce intricate parts with exceptional accuracy, owing to their programmed commands and automated operations. This technology minimizes human error and allows for the replication of complex designs with consistency, making them ideal for industries that require high tolerance components.

Another advantage of CNC milling machines is their efficiency. Unlike manual milling, where operators must continuously adjust settings and monitor the machining process, CNC machines automate these tasks. This results in faster production times and the ability to run operations continuously, even overnight, without the need for constant supervision. As a result, manufacturers can significantly increase output while reducing labor costs, enhancing the overall productivity of the manufacturing process. The combination of precision and efficiency makes CNC milling machines an indispensable tool in modern manufacturing, driving innovation and quality across various sectors.

Analyzing Precision: How CNC Technology Reduces Tolerances in Manufacturing

The CNC technology is transforming the landscape of modern manufacturing by significantly reducing tolerances in production processes. With the global machine tool market expected to climb from $132.63 billion in 2025 to $229.46 billion by 2032, reflecting a compound annual growth rate (CAGR) of 8.1%, the importance of precision in manufacturing is more critical than ever. CNC machines allow manufacturers to achieve remarkable accuracy, consistently producing parts that meet stringent specifications, thereby enhancing overall product quality.

As industries increasingly embrace digital manufacturing technologies, the demand for high-precision and efficient operations is growing. The machine tool software market alone, valued at $520 million in 2022, is anticipated to reach $880 million by 2030, with a CAGR of 7.2% from 2024 to 2030. This trend underscores the shift towards automated solutions that reduce manual intervention, resulting in diminished errors.

**Tips:** When selecting CNC machines, prioritize those that offer advanced features like adaptive control and real-time monitoring, which can further enhance precision. Additionally, consider investing in comprehensive software solutions that can integrate seamlessly with your existing systems to maximize efficiency and reduce production downtime.

Revolutionizing Precision with CNC Metal Milling Machines for Modern Manufacturing

| Attribute | Value |

|---|---|

| Precision Tolerance | ±0.005 mm |

| Material Types | Aluminum, Steel, Titanium |

| Maximum Milling Speed | 12000 RPM |

| Typical Applications | Aerospace, Automotive, Medical Devices |

| Setup Time | Less than 30 minutes |

| Software Used | CAD/CAM Integration |

| Average Cycle Time | Varies by part complexity |

Industry Trends: The Growth of CNC Milling in Aerospace and Automotive Sectors

The aerospace and automotive sectors are experiencing a transformative shift driven by the rising adoption of CNC milling technologies. As the demand for precision engineering escalates, industries are increasingly integrating advanced CNC milling machines into their manufacturing processes. This integration not only enhances precision but also streamlines production workflows, enabling companies to meet the rigorous standards required in both the aerospace and automotive fields.

Recent market forecasts indicate significant growth within the CNC milling landscape, with the global milling machine market projected to increase substantially from USD 75,161 million in 2025 to USD 116,722.7 million by 2035. Factors such as advancements in smart automation, multi-axis machining capabilities, and heightened demand for high-precision components are driving this expansion. As manufacturers strive to enhance operational efficiency and product accuracy, the role of CNC milling machines is set to become even more pivotal, positioning these technologies at the heart of modern manufacturing strategies.

Cost-Benefit Analysis: Investing in CNC Milling for Long-Term Manufacturing Success

The landscape of modern manufacturing is rapidly evolving with the advent of CNC metal milling machines, which are proving to be essential for improving precision and efficiency. Investing in CNC milling technologies is becoming increasingly favorable from a cost-benefit perspective. The integration of these machines not only enhances production capabilities but also reduces labor costs and material waste, making them a cornerstone for manufacturers aiming for long-term success.

Tips for manufacturers considering CNC milling investments include conducting a thorough cost analysis. Assess both the initial capital expenditure and the anticipated savings over time. Additionally, focus on training staff to operate these machines effectively; skilled operators can maximize the benefits of precision machining. Another important consideration is to stay updated on technological advancements, as the integration of automation can further improve efficiency and output.

As the manufacturing industry embraces digital transformation, overcoming challenges associated with technology adoption becomes crucial. Manufacturers must strategize to navigate barriers and effectively implement innovations like CNC milling. By understanding the market dynamics and preparing for the future needs of the industry, companies can position themselves for sustained growth and competitive advantage.

Related Posts

-

Innovative Trends for Best CNC Machine Milling Machine in 2025 Shaping the Future of Manufacturing

-

Exploring CNC Milling Machine Innovations at the 2025 China Import and Export Fair

-

Navigating the Future: 2025 Market Insights and How to Choose the Best Basic CNC Machine

-

Top Strategies for Choosing the Best CNC Milling Machine for Your Business Needs

-

10 Digital Tips for Choosing the Perfect Micro CNC Milling Machine for Your Business Needs

-

Unleashing Global Excellence in CNC Milling Machines with Premium Quality from China