Revolutionizing Precision: Exploring the Impact of CNC Turning Machines on Modern Manufacturing

The manufacturing industry has undergone a remarkable transformation in recent years, driven by advancements in technology and automation. Among these innovations, the CNC turning machine stands out as a pivotal tool that enhances precision and efficiency in production processes. According to a report by IBISWorld, the global CNC machining market was valued at approximately $89 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of 6.7% through 2025, highlighting the increasing reliance on advanced machining solutions. These machines not only improve the accuracy of complex part production but also reduce waste and operational costs, thereby revolutionizing traditional manufacturing methods. As industries shift towards smarter manufacturing practices, understanding the impact of CNC turning machines is crucial for companies aiming to stay competitive in a rapidly evolving marketplace.

The Evolution of CNC Turning Machines in Manufacturing

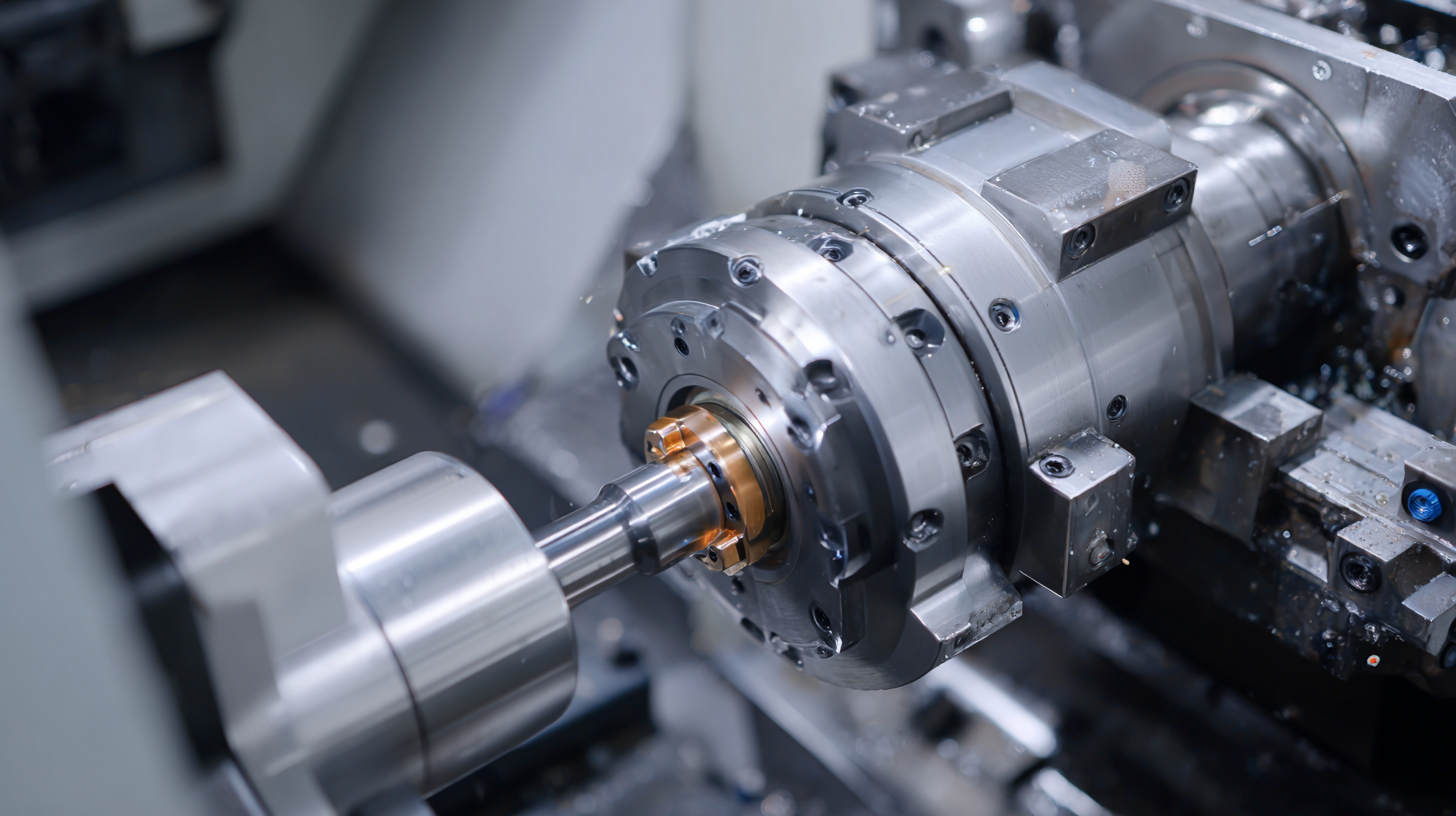

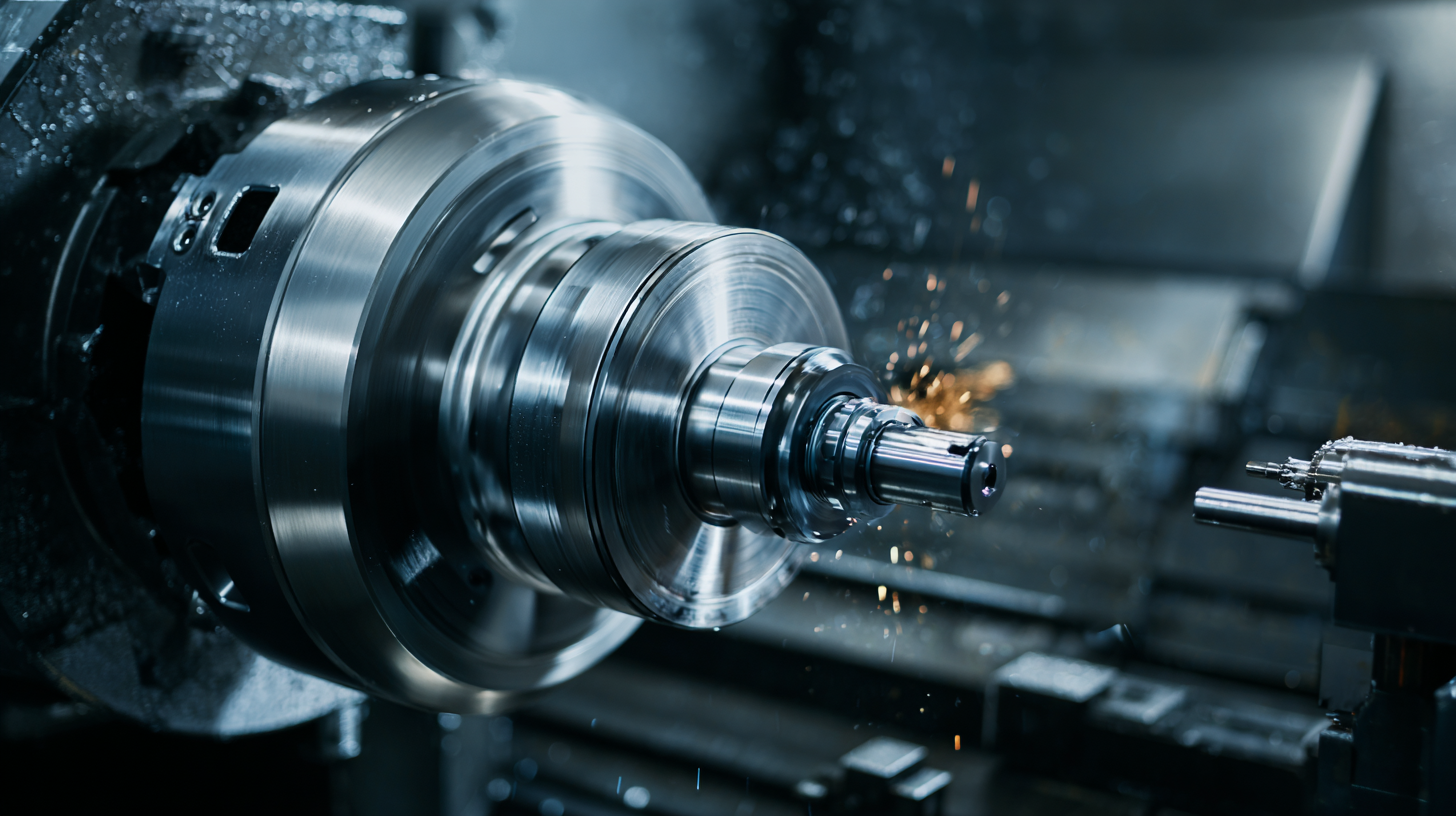

The evolution of CNC turning machines represents a significant leap forward in modern manufacturing, where precision and efficiency are paramount. Recent advancements, such as the introduction of advanced twin-spindle turning centers, have set new benchmarks for speed and versatility in bar-fed machining applications. This innovation underscores a broader trend toward optimizing manufacturing processes, integrating cutting-edge technology to enhance productivity and deliver superior accuracy.

Moreover, the influence of artificial intelligence (AI) in the CNC machinery landscape cannot be overstated. The rise of self-optimized machine cutting techniques is driving a transformative shift in market dynamics, bolstering demand for high-precision multi-axis machining centers. As manufacturers increasingly adopt smart technologies and automated solutions, the CNC turning machine sector is poised for robust growth, addressing the challenges of contemporary production environments while meeting the needs of an evolving market.

Revolutionizing Precision: Exploring the Impact of CNC Turning Machines on Modern Manufacturing

| Dimension | Description | Impact on Manufacturing | Trends |

|---|---|---|---|

| Accuracy | Precision in machining parts to tight tolerances | Increased product quality and reduced waste | Growing use of CAD/CAM integration |

| Efficiency | Reduced cycle times through automation | Lowering manufacturing costs | Increased automation and smart factories |

| Flexibility | Ability to switch between different production runs | Meeting diverse customer demands | Trend towards customization in production |

| Cost-effectiveness | Lower labor costs and reduced material waste | Increased profitability for manufacturers | Focus on lean manufacturing practices |

| Innovation | Integration of advanced technologies such as IoT and AI | Enhancement of production processes | Use of predictive maintenance and real-time monitoring |

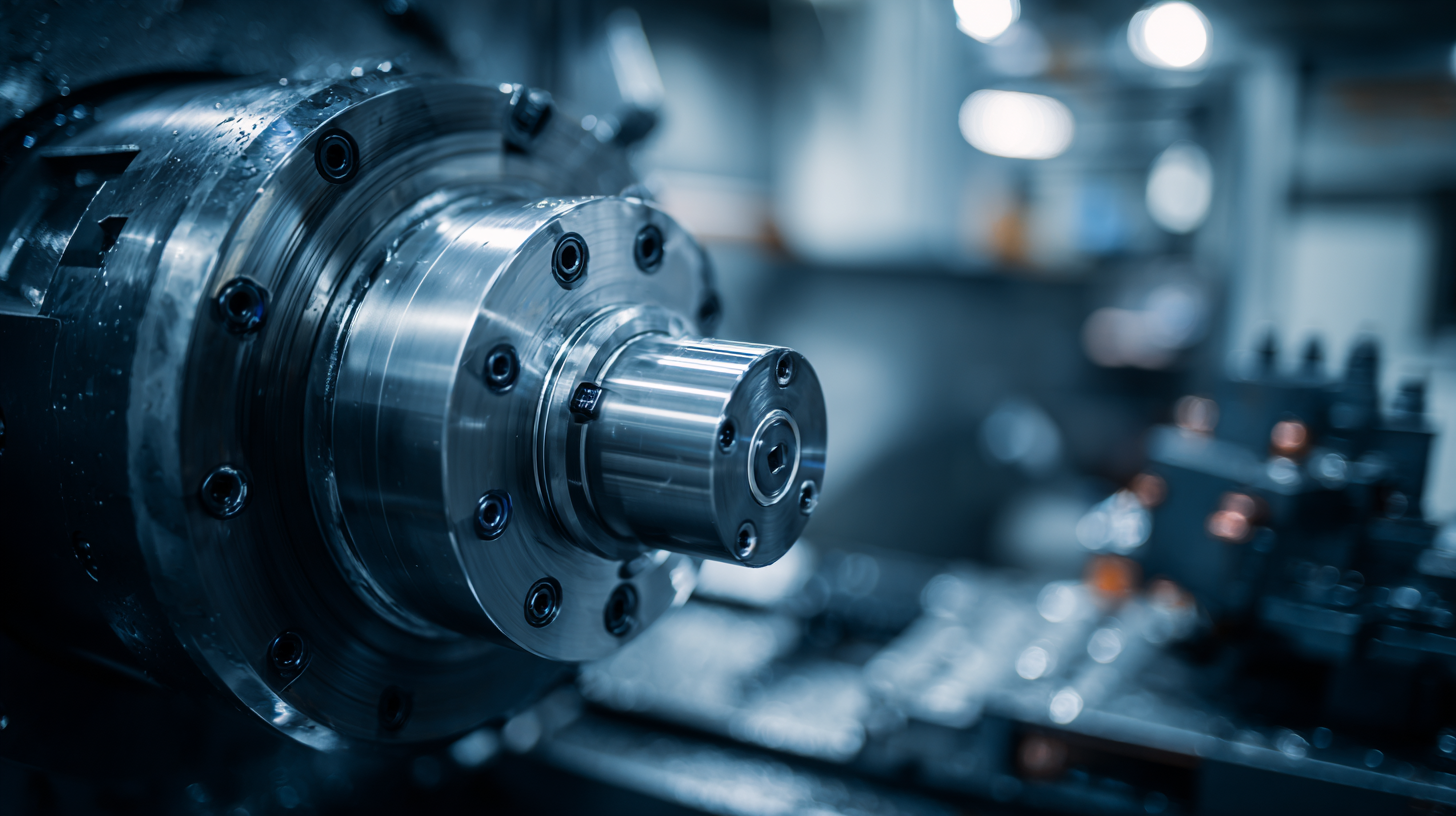

Key Features of CNC Turning Technology: Precision and Efficiency

CNC turning technology has transformed modern manufacturing by enhancing precision and efficiency in the production process. At the heart of this revolution is the ability of CNC (Computer Numerical Control) machines to produce intricate components with exceptionally tight tolerances. This level of accuracy is crucial for industries such as aerospace, automotive, and medical devices, where even the slightest deviation can lead to significant functional failures or safety issues. The automation provided by CNC turning machines minimizes human error, ensuring consistency and superior quality in each production cycle.

CNC turning technology has transformed modern manufacturing by enhancing precision and efficiency in the production process. At the heart of this revolution is the ability of CNC (Computer Numerical Control) machines to produce intricate components with exceptionally tight tolerances. This level of accuracy is crucial for industries such as aerospace, automotive, and medical devices, where even the slightest deviation can lead to significant functional failures or safety issues. The automation provided by CNC turning machines minimizes human error, ensuring consistency and superior quality in each production cycle.

Another key feature of CNC turning technology is its efficiency in terms of time and resources. Traditional machining methods often require extensive manual setup and adjustments, whereas CNC machines can be programmed to run complex operations with minimal intervention. This capability not only accelerates the manufacturing process but also allows for greater flexibility in production runs. Manufacturers can swiftly change designs or specifications without significant downtime, making it an ideal solution for both mass production and custom projects. Furthermore, CNC turning machines optimize material use, reducing waste and lowering production costs while maintaining high standards of quality.

Comparative Analysis: CNC Turning vs. Traditional Machining Methods

CNC turning machines have significantly transformed the landscape of modern manufacturing, offering advantages that traditional machining methods often struggle to match. One of the critical distinctions lies in precision and consistency; CNC turning utilizes computer numerical control, allowing for intricate designs to be produced with astonishing accuracy. This level of precision minimizes human error, leading to higher-quality parts and components, which is essential in industries where even the slightest deviation can have dire consequences.

In contrast, traditional machining methods, which often rely on manual inputs and adjustments, can face limitations in achieving the same level of precision consistently. While skilled machinists bring valuable expertise, their work is still subject to variability due to fatigue, the manual setup process, and the intricacies of machine operation. Additionally, CNC turning machines can operate continuously without breaks, facilitating increased production rates and efficiency. This technology not only ramps up output but also allows for complex parts to be made in shorter time frames, thereby enhancing competitiveness in a fast-paced market.

The Role of CNC Turning in Industry 4.0 and Smart Manufacturing

CNC turning machines are at the forefront of the evolution of manufacturing, playing a crucial role in Industry 4.0 and smart manufacturing. These advanced machines utilize computer numerical control to ensure high levels of precision and efficiency, streamlining production processes across various sectors. As industries adopt these technologies, they experience significant boosts in productivity, enhancing their capabilities to meet the growing demands of today's market.

Tips for maximizing the benefits of CNC turning machines include investing in training for operators to ensure they can leverage the technology effectively. Additionally, regularly updating software and maintaining equipment can prevent downtime and extend machinery life. Companies should also consider integrating data analytics to monitor performance and optimize production, driving further improvements in efficiency and output.

The CNC machine market is projected to see substantial growth, with expectations to reach USD 170.4 billion by 2033. This reflects a broader trend where automation and digital solutions are reshaping how companies approach manufacturing. As the Industrial and Manufacturing Engineering Departments, like the one at Cal Poly Pomona, promote innovation through new labs and resources, industries must continue to embrace these changes to maintain competitiveness in an ever-evolving landscape.

Impact of CNC Turning Machines on Manufacturing Productivity

This chart illustrates the productivity gains achieved through the adoption of CNC turning machines across various sectors in modern manufacturing. The data reflects time savings in hours per unit across three key industries: Automotive, Aerospace, and Electronics.

Future Trends: Innovations Shaping the Next Generation of CNC Turning Machines

The future of CNC turning machines is being shaped by groundbreaking innovations that enhance efficiency and precision in manufacturing processes. These advancements are driven by the increasing adoption of digital technologies, which allow for better integration and automation within production systems. As manufacturers strive for higher productivity and lower operational costs, cutting-edge features such as advanced sensor technology and AI-driven analytics are becoming essential. These innovations not only streamline processes but also enable real-time monitoring and adjustments, ensuring optimal performance across various applications.

Upcoming events like DISCOVER 2025 and DIMF 2025 underscore the industry's commitment to showcasing these transformative technologies. By highlighting the latest developments, these exhibitions provide a platform for industry leaders to share insights and innovations that will define the next generation of CNC turning machines. The focus on multi-axis machining centers and high-precision capabilities indicates a shift towards more complex manufacturing solutions, meeting the demand for versatility in production while enhancing the accuracy of finished products.

Related Posts

-

Discover World-Class Manufacturing: Elevate Your Production with the Best CNC Turning Machine from China

-

What is the Best CNC Turning Machine for Your Manufacturing Needs?

-

Ultimate Guide to Selecting the Best CNC Lathe Machine for Your Business Needs

-

Navigating Global Trade: Understanding Import and Export Certifications for the Best Types of CNC Machines

-

Chinese Smart Manufacturing Leading the World with the Best Basic CNC Machine Quality Assurance

-

Ultimate Guide to Choosing the Best Types of CNC Machines for Your Business Needs