What is a Prototype Machine and How Does It Work?

A prototype machine is an essential tool in product development. It serves as a model to test ideas and functionality. By creating a prototype machine, designers can visualize concepts before mass production. This process reduces errors and uncovers potential issues early.

Designing a prototype machine requires creativity and technical skill. It often involves trial and error, leading to unexpected challenges. Not every prototype will work perfectly. Some may fail to meet initial expectations. However, each setback provides valuable insights for improvement.

Understanding how a prototype machine operates is crucial for innovators. It can simulate real-world conditions and allow for adjustments based on feedback. Ultimately, it is a critical step in transforming ideas into reality. The journey can be messy, filled with reflections on what works and what doesn’t. Embracing this imperfect process fosters growth and innovation.

What is a Prototype Machine?

A prototype machine is a crucial tool in the development of products. It allows designers and engineers to test ideas before mass production. According to a recent industry report, over 70% of companies agree that prototyping significantly reduces development time. This efficiency is vital in a competitive market where time-to-market can determine success.

In essence, prototype machines simulate the functions of the final product. They can range from simple handmade models to advanced 3D-printed items. These machines help identify flaws early in the design process. A 2023 study found that nearly 60% of prototype evaluations uncovered critical design issues that may have gone unnoticed otherwise. However, some prototypes fall short of capturing real-world conditions, which can lead to misleading results.

Engineers are constantly learning from prototypes. While they are valuable, prototypes are not perfect. This feedback loop can sometimes take longer than expected. It is essential to reflect on the insights gained and continuously adapt designs. By doing so, companies can enhance their products while minimizing costly errors in the later stages of development.

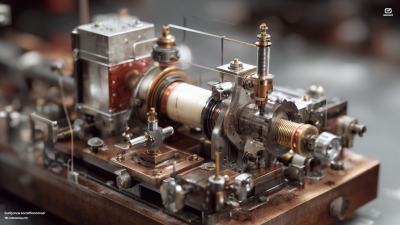

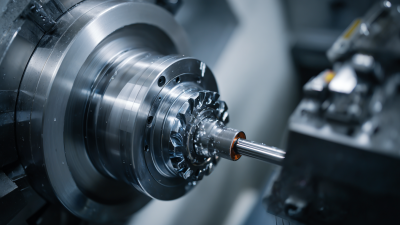

Key Components of a Prototype Machine

A prototype machine is an essential tool in product development. Its main purpose is to test concepts and refine designs. Understanding the key components of a prototype machine helps in creating effective prototypes.

The frame provides structure and stability. It needs to be sturdy yet lightweight for easy handling. The power source drives the machine. It can be electric, pneumatic, or hydraulic. Each option has its advantages and drawbacks. Control systems allow users to manage the machine’s operations. These can range from simple switches to complex programmable interfaces.

Sensors play a crucial role in gathering data. They detect various parameters like temperature, pressure, and speed. This information helps in making informed decisions. Flexible components, such as interchangeable parts, allow for quick adjustments. Designers often overlook this aspect. However, the ability to iterate is vital. Building a prototype should be about adaptability and learning from failures. Mistakes can reveal insights that lead to better designs. In the world of prototype machines, refinement is key.

Prototype Machine Performance Metrics

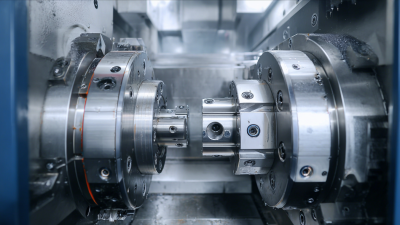

Understanding the Working Mechanism of Prototype Machines

Prototype machines play a crucial role in product development. They allow designers and engineers to test concepts quickly. This helps identify flaws early in the design process. A prototype machine often uses materials similar to the final product. However, the choice of materials can impact the testing results. Sometimes, these machines do not perfectly replicate the final version. This can lead to unexpected challenges.

The working mechanism of prototype machines varies. Typically, they integrate components that simulate functionality. A common example is a 3D printer, which creates physical models from digital designs. This process offers immediate feedback. Issues may arise, such as misalignment or material limitations. These imperfections are valuable learning opportunities. Designers must adapt and refine their ideas based on these insights.

In some cases, immediate production is not feasible. Iterations may result in several prototypes before reaching a final design. This trial and error can be time-consuming. Yet, it often leads to better end products. Each prototype tests a specific aspect, like ergonomics or durability. Despite these efforts, there are always unforeseen variables. These can derail timelines and budgets, reminding teams to remain flexible.

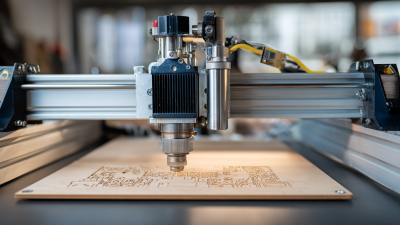

Applications of Prototype Machines in Various Industries

Prototype machines play a crucial role across various industries. In manufacturing, they help design and test products before full-scale production. For instance, a prototype of a consumer gadget can reveal flaws early. This can save time and reduce costs. Often, the first version may not meet expectations. Engineers tweak designs based on feedback and testing results.

In the automotive sector, prototype machines are essential. They allow for the development of new vehicle designs. By creating a prototype, engineers can assess aerodynamics and safety features. Early tests may show unexpected issues, requiring adjustments. This iterative process ensures the final product is reliable and safe.

Healthcare also benefits significantly from prototype machines. Medical devices undergo rigorous prototyping to ensure effectiveness. A prototype of a surgical tool might reveal design limitations. Refining these tools leads to better patient outcomes. In many cases, initial designs need reconsideration. This constant refinement underpins innovation in healthcare technology.

What is a Prototype Machine and How Does It Work? - Applications of Prototype Machines in Various Industries

| Industry | Prototype Machine Type | Application | Material Used | Benefits |

|---|---|---|---|---|

| Automotive | 3D Printer | Prototype car parts | Plastic, Metal | Cost-effective, Rapid production |

| Consumer Electronics | CNC Machine | Prototype housing | Aluminum, ABS | Precision, High quality |

| Aerospace | Stereolithography | Prototype wing components | Resin | Lightweight, Complex shapes |

| Medical | Laser Cutting | Prototype surgical tools | Stainless Steel | Sterilizable, Durable |

| Architecture | 3D Modeling Software | Building models | Various materials | Visual representation, Improved design |

Benefits of Using Prototype Machines in Product Development

Prototype machines play a crucial role in product development. These tools enable designers and engineers to create tangible versions of their ideas. This hands-on approach promotes better understanding and refinement of concepts. According to a report from the National Institute of Standards and Technology, organizations that incorporate prototype machines reduce their time-to-market by 20%.

Using prototype machines can significantly enhance collaboration within teams. When everyone can interact with a physical model, communication becomes clearer. Designers can gather instant feedback. This immediacy helps identify flaws early in the process. However, the initial costs related to prototype machines can be a barrier for some companies.

Despite these challenges, the benefits are substantial. Prototyping helps to visualize complex ideas, making it easier to verify features and functionalities. A study from McKinsey indicates that teams using prototype machines see a 30% increase in innovation speed. While some may overlook prototyping, its strategic importance in product development should not be underestimated. Each prototype iteration leads to a more refined final product.

Related Posts

-

Unlocking the Full Potential of the Best Prototype Machine with Detailed Specifications and Usage Guide

-

How to Choose the Best Home CNC Machine for Your DIY Projects

-

Unlocking Your CNC Aluminium Machine Potential 5 Essential Tips for Global Buyers

-

2024 Ultimate Guide to Best Mill Turn Machines for Global Buyers

-

Revolutionizing Precision with CNC Metal Milling Machines for Modern Manufacturing

-

The Future of Innovative Aluminium Milling Machines in Global Manufacturing