Precision Engineering in China: Elevating Global Manufacturing with the Best Metal CNC Machines

In the rapidly evolving landscape of global manufacturing, metal CNC machines have emerged as a cornerstone of precision engineering, particularly in China. As one of the largest manufacturing hubs in the world, China is not only adopting advanced technology but also innovating its methodologies to address various problems inherent in traditional manufacturing processes. This blog delves into the pivotal role of metal CNC machines in enhancing production efficiency, accuracy, and adaptability, while also tackling common challenges faced by manufacturers. From optimizing workflow to improving material utilization, the insights shared here will illuminate how Chinese precision engineering is setting new standards in the global manufacturing arena, making it imperative for industry stakeholders to understand and embrace these advancements.

The Evolution of Precision Engineering in China's Manufacturing Sector

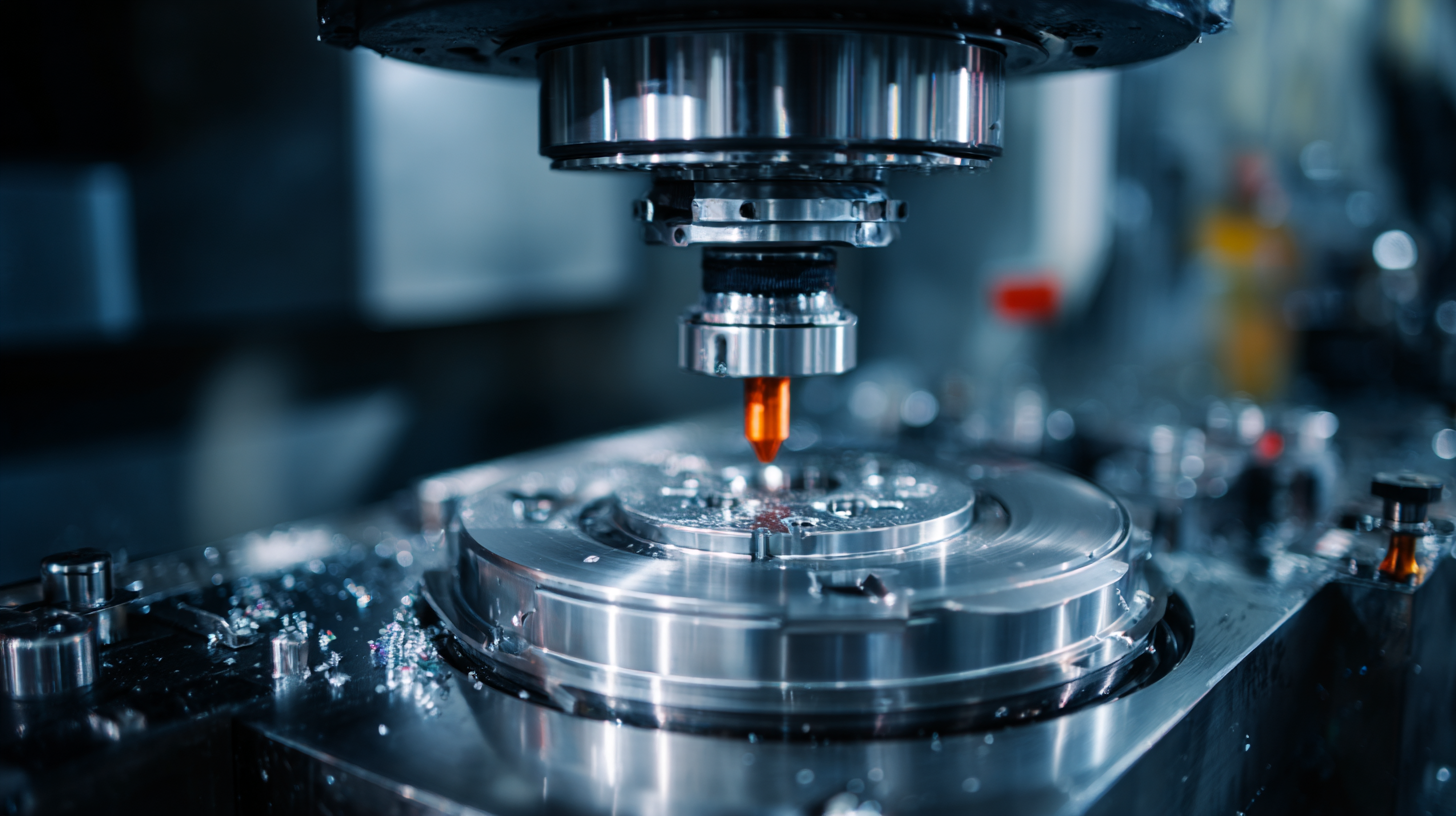

The evolution of precision engineering in China's manufacturing sector has marked a significant shift towards advanced technologies, underscoring the country's commitment to enhancing global manufacturing standards. Over the past few decades, China has transformed from a low-cost manufacturing hub to a leader in sophisticated engineering solutions, particularly in the realm of CNC machines. These machines have become indispensable in various industries, offering unparalleled accuracy and efficiency in metal cutting and forming processes.

This evolution is not only evident in the manufacturing capabilities but also in the research and development efforts that accompany them. With a focus on integrating automation and artificial intelligence, Chinese manufacturers are now poised to compete on a global scale, driving innovations that redefine productivity. As they continue to invest in cutting-edge technologies, China's role in the international market is becoming increasingly influential, setting the stage for a new era of precision engineering where efficiency and quality are paramount.

Precision Engineering in China: Elevating Global Manufacturing with the Best Metal CNC Machines

| Category | CNC Machine Type | Precision (µm) | Production Rate (units/hour) | Application Fields |

|---|---|---|---|---|

| High-Speed Machining | CNC Milling Machine | 5 | 200 | Aerospace, Automotive |

| Precision Machining | CNC Turning Machine | 1 | 150 | Medical Devices, Electronics |

| Additive Manufacturing | 3D Metal Printer | 50 | 30 | Prototyping, Aerospace |

| Advanced Fabrication | Laser Cutting Machine | 20 | 100 | Sheet Metal, Structures |

Key Technologies Driving Metal CNC Machine Advancements

Precision engineering is a pivotal force in the evolution of global manufacturing, particularly in the realm of metal CNC machines. Recent advancements in key technologies are shaping the future of metal machining, responding to the rising demands of industries such as oil and gas. As the market is projected to grow significantly from 2024 to 2028, with an estimated increase in revenue driven by these sectors, the relevance of CNC technologies becomes ever more pronounced.

Precision engineering is a pivotal force in the evolution of global manufacturing, particularly in the realm of metal CNC machines. Recent advancements in key technologies are shaping the future of metal machining, responding to the rising demands of industries such as oil and gas. As the market is projected to grow significantly from 2024 to 2028, with an estimated increase in revenue driven by these sectors, the relevance of CNC technologies becomes ever more pronounced.

Among the leading innovations are AI-powered CNC machines, which are enhancing precision and efficiency in production processes. The integration of artificial intelligence into machining not only streamlines operations but also significantly reduces the margin for error. Moreover, advancements in rapid prototyping processes, including laser cutting and 3D printing, are transforming how manufacturers approach product design and development, enabling quicker iterations and flexibility.

Tips for manufacturers: To stay competitive, consider investing in AI-driven CNC machines that optimize production. Regularly updating your machinery with the latest technologies will not only enhance precision but also improve overall productivity. Lastly, embrace sustainable machining practices to minimize environmental impacts, ensuring compliance with regulatory standards while appealing to eco-conscious consumers.

Comparative Analysis: China’s CNC Machines vs. Global Competitors

China's CNC machines have positioned themselves as formidable contenders on the global stage, prompting a detailed comparative analysis against their international counterparts. The global stone processing machine market, valued at $7.56 billion in 2022, is projected to escalate to $11.45 billion by 2030, indicating a significant shift in manufacturing dynamics. China's advancements in precision engineering and manufacturing technologies are a critical factor behind this growth, creating competitive pressures particularly in industries like automotive and chemicals where China has made substantial inroads.

When considering the advantages of Chinese CNC machines, one notable aspect is their cost-efficiency and scalability. For manufacturers looking to optimize their production processes, investing in high-quality CNC equipment from China can lead to increased productivity without compromising on precision.

Tip: Businesses should evaluate their specific manufacturing needs and potential return on investment when considering CNC machine options.

Furthermore, the ongoing globalization of supply chains suggests that integrating advanced CNC capabilities can enhance operational flexibility and responsiveness to market demands. Extra measures should be taken to stay abreast of technological advancements, especially as China continues to innovate and shape global manufacturing trends.

Tip: Regularly analyze market reports and technological advancements to stay competitive; knowledge is key in leveraging the best machinery for your business needs.

Real-World Applications of CNC Machining in Various Industries

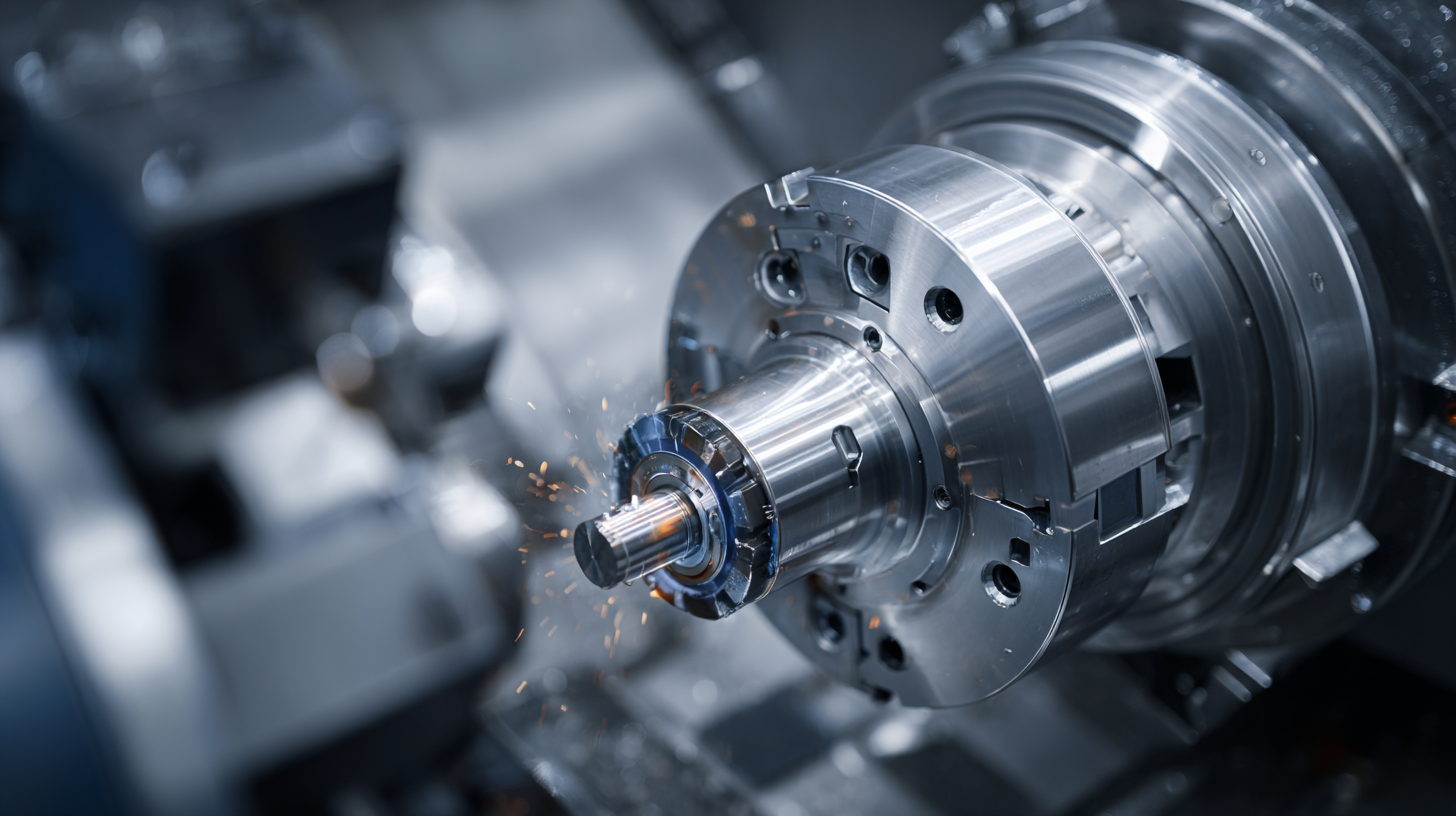

CNC (Computer Numerical Control) machining has revolutionized manufacturing across diverse industries, enhancing precision and efficiency in production processes. According to a report from Grand View Research, the global CNC machines market size was valued at approximately $67 billion in 2021 and is projected to expand at a compound annual growth rate (CAGR) of 6.5% from 2022 to 2030. This growth underscores the transformative role that CNC technology plays in sectors such as aerospace, automotive, and medical device manufacturing.

In the aerospace industry, for instance, CNC machining is crucial for producing intricate components, ensuring that parts meet stringent safety and quality standards. A study by Frost & Sullivan indicates that the demand for lightweight structures in aerospace applications has accelerated the use of advanced CNC machines, projected to account for over 25% of the market by 2025. Similarly, in the medical field, hospitals and manufacturers are increasingly turning to CNC technology to create customized surgical instruments and implants, enabling more accurate and efficient patient care while adhering to rigorous regulatory requirements. This trend reflects a broader movement towards automation and precision in manufacturing, which is essential for maintaining competitiveness in the global market.

Future Trends in Precision Engineering and Metal CNC Manufacturing in China

Precision engineering is rapidly transforming the metal manufacturing landscape in China, fueled by advancements in CNC (Computer Numerical Control) technology. As the global CNC machine market is projected to grow from $101.2 billion in 2025 to an astounding $195.6 billion by 2032, with a compound annual growth rate (CAGR) of 9.9%, China is positioning itself as a key player in this sector. The demand for high-precision metal components in industries such as automotive and aerospace is driving investments in state-of-the-art CNC machines, elevating manufacturing standards and efficiency.

Furthermore, the desktop CNC machine market is anticipated to witness significant growth, with projections reaching $36.9 billion by 2032. This rise is attributed to the increasing adoption of desktop solutions for both hobbyists and small businesses, enabling more accessible entry into precision manufacturing. As China's manufacturing capabilities continue to expand, the integration of advanced technologies, including 3D printing and titanium metal processing, is expected to open new avenues for innovative applications and redefine traditional manufacturing boundaries. With these trends, China is not just enhancing its domestic production capabilities but is also set to influence global manufacturing paradigms significantly.