Discovering Precision CNC Milling Machine Alternatives for Enhanced Manufacturing Solutions

In the ever-evolving landscape of manufacturing, the demand for precision and efficiency has never been greater. According to a recent industry report by MarketsandMarkets, the global CNC machining market is projected to reach USD 102.2 billion by 2025, growing at a CAGR of 6.5%. This surge underscores the critical importance of precision CNC milling machines in modern production processes. However, manufacturers are increasingly exploring alternatives that offer enhanced functionalities, reduced costs, and improved adaptability. As companies strive to optimize their manufacturing solutions, understanding the benefits of various milling machine types becomes essential for staying competitive. By investigating these alternatives, businesses can leverage the latest advancements in technology to achieve better precision, reduced lead times, and greater overall productivity.

Understanding the Basics of CNC Milling and Its Importance in Manufacturing

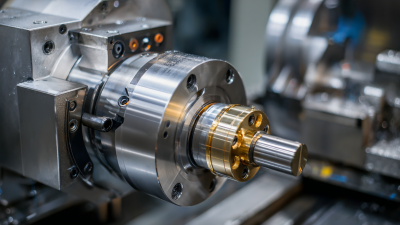

CNC milling is a pivotal process in modern manufacturing, enabling precision and efficiency in the creation of intricate components. At its core, CNC (Computer Numerical Control) milling utilizes computerized controls to guide machinery in shaping materials such as metal, plastic, and wood. This technology allows for high levels of accuracy and repeatability, reducing the risk of human error and ensuring that each part meets stringent specifications.

Understanding the fundamentals of CNC milling is crucial for manufacturers seeking to enhance their production capabilities. The process involves various techniques, from basic cutting and drilling to more complex operations like contouring and pocketing. The ability to manipulate multiple axes simultaneously further amplifies the versatility of CNC milling machines. As industries continue to evolve, exploring alternative solutions alongside traditional CNC milling can lead to innovative manufacturing strategies that improve efficiency and reduce costs. Embracing this shift not only fosters adaptability but also positions businesses to meet the growing demands of the market.

Manufacturing Solutions: CNC Milling Machine Alternatives

This bar chart illustrates the market share of various manufacturing methods, highlighting CNC milling as the dominant approach. Alternatives such as manual milling and 3D printing are also represented, showcasing the diverse landscape of manufacturing solutions.

Exploring the Benefits of Alternative Milling Technologies

The world of manufacturing is continually evolving, and with this evolution comes the need for innovative solutions that can meet the diverse demands of production. Alternative milling technologies offer manufacturers a unique way to enhance their machining processes while addressing limitations associated with traditional CNC milling machines. Options such as additive manufacturing, laser cutting, and water jet machining provide distinctive advantages, particularly in precision and material versatility.

One of the primary benefits of these alternative milling technologies is their ability to work with a broader range of materials, including both metals and composites. For instance, laser technology allows for intricate designs and high precision, making it ideal for projects that require detailed work with minimal waste. Furthermore, water jet cutting is known for its capability to handle thick materials without introducing heat, preserving the integrity of the substrate and offering a clean finish that traditional milling methods may not achieve.

One of the primary benefits of these alternative milling technologies is their ability to work with a broader range of materials, including both metals and composites. For instance, laser technology allows for intricate designs and high precision, making it ideal for projects that require detailed work with minimal waste. Furthermore, water jet cutting is known for its capability to handle thick materials without introducing heat, preserving the integrity of the substrate and offering a clean finish that traditional milling methods may not achieve.

Adopting these alternatives not only enhances manufacturing flexibility but also improves overall efficiency. With lower operational costs and reduced setup times, manufacturers can respond quickly to market changes and customer demands. This adaptability is essential for staying competitive in a fast-paced industry. Ultimately, exploring these milling alternatives empowers manufacturers to optimize their production processes, innovate new products, and drive growth in their organizations.

Comparative Analysis: CNC Milling vs. 3D Printing and Additive Manufacturing

As manufacturers seek greater efficiency and innovation, the debate between traditional CNC milling and modern 3D printing, or additive manufacturing, becomes increasingly pertinent. CNC milling, a subtractive manufacturing process, offers precision and reliability, making it ideal for creating intricate components from a variety of materials. However, this process can be limited by tooling costs and the need for extensive setup time. In contrast, 3D printing enables rapid prototyping and design flexibility, allowing for complex geometries that CNC milling may struggle to achieve without significant time and financial investment.

When it comes to material usage, CNC milling typically generates waste, as material is cut away from a solid block. On the other hand, additive manufacturing builds parts layer by layer, meaning that only the necessary material is utilized. This aspect not only reduces waste but also opens the door to more sustainable practices within manufacturing. Furthermore, as 3D printing technologies continue to evolve, they are expanding the range of materials that can be used, from plastics to metals, challenging the traditional domains of CNC milling. Each method offers distinct advantages and limitations, making the choice between them essential based on the specific needs of a project.

Identifying Key Features to Look for in CNC Milling Machine Alternatives

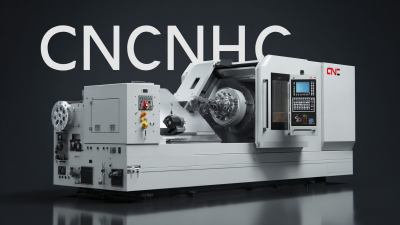

When searching for CNC milling machine alternatives, it's essential to identify key features that can enhance your manufacturing solutions. First and foremost, consider the machine's precision and accuracy. Precision machining can significantly reduce waste and rework, making it critical to choose an alternative that maintains tight tolerances. Look for machines that offer advanced control systems and superior spindle performance, as these attributes can lead to improved part quality and efficiency.

Another vital aspect to evaluate is the versatility of the CNC milling machine alternative. A machine capable of performing various operations—such as drilling, tapping, and contouring—can optimize your workflow and reduce the need for multiple setups. Additionally, assess the ease of programming, as user-friendly interfaces and compatibility with different CAD/CAM software can enhance productivity.

Lastly, consider the machine's build quality and support services. Investing in a durable machine backed by strong customer support can ensure uninterrupted operations and minimize downtime in your manufacturing process.

Future Trends in Milling Technology: What Manufacturers Should Anticipate

As the manufacturing landscape evolves, the future of milling technology promises significant advancements that manufacturers must embrace. One of the most notable trends is the integration of smart technology and automation into milling operations. IoT-enabled CNC machines can provide real-time data analytics, allowing manufacturers to monitor performance and predict maintenance needs. This not only minimizes downtime but also enhances overall operational efficiency, helping businesses stay competitive in a rapidly changing market.

Another critical trend is the rise of additive manufacturing techniques being combined with traditional milling processes. These hybrid approaches enable manufacturers to create complex geometries and reduce material waste, leading to more sustainable practices. Additionally, as the demand for customized products grows, milling technology will increasingly focus on flexibility and adaptability. Manufacturers that invest in diverse milling solutions will find themselves better equipped to meet the unique needs of their clientele, paving the way for innovation and growth in the years to come.

Related Posts

-

Discover How Top Chinese Factories Redefine Excellence in Precision CNC Milling Machines

-

Top Strategies for Choosing the Best CNC Milling Machine for Your Business Needs

-

2025 Precision CNC Milling Machine Innovations: Your Ultimate Checklist for Success

-

China's Best Precision CNC Milling Machines Deliver Global Quality You Can Trust

-

Unveiling the Specifications: The Ultimate Guide to the Best CNC Lathe Machine for Global Buyers

-

Innovative Solutions for Effective Use of Best Types of CNC Machines