10 Essential Tips for Maximizing Efficiency with Your CNC Lathe and Milling Machine

In today's competitive manufacturing landscape, optimizing the performance of your CNC lathe and milling machine is crucial for achieving operational excellence. According to a report by the American Society of Mechanical Engineers, nearly 60% of manufacturing companies are turning to advanced machining technologies to enhance productivity and reduce costs. CNC machines are at the forefront of this transformation, offering precision and versatility that traditional methods simply cannot match. However, many operators still fall short of fully leveraging the capabilities of their CNC lathe and milling machine. By implementing best practices and employing strategic techniques, manufacturers can not only maximize their efficiency but also significantly decrease production time and waste. In this blog, we will explore ten essential tips that can elevate your machining processes and help you stay ahead in the fast-paced manufacturing environment.

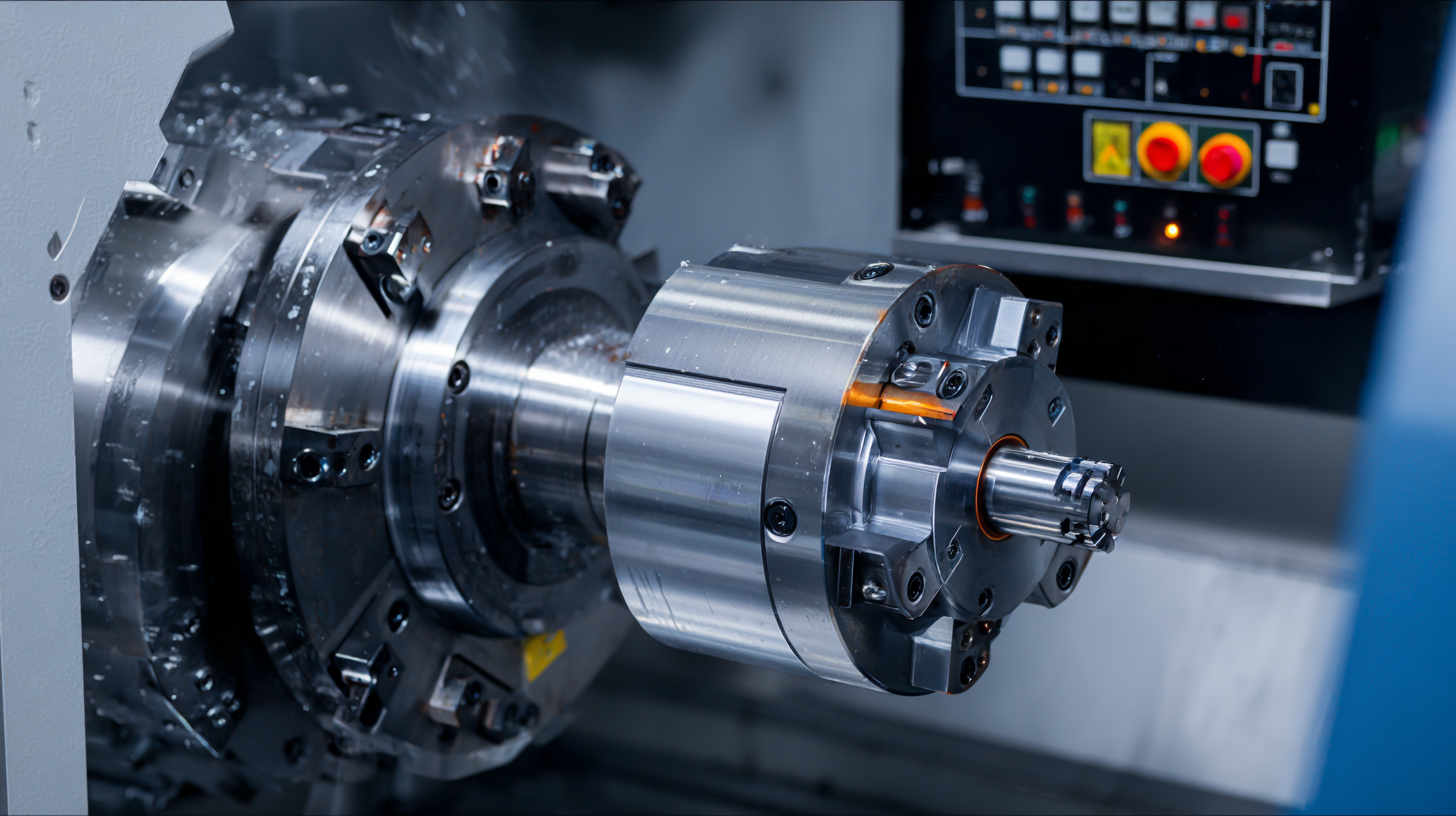

Understanding Your CNC Lathe and Milling Machine's Capabilities

Understanding the capabilities of your CNC lathe and milling machine is essential for maximizing efficiency in your machining operations. CNC machining involves the use of computer numerical control to manipulate tools and materials with high precision. According to industry reports, CNC machines can increase production efficiency by up to 25% when utilized effectively. This boost often stems from the advanced capabilities these machines offer, including multi-axis operations and the ability to create complex geometries without manual intervention.

One critical component in optimizing CNC machining processes is the use of post processors. These software tools translate CAD models into machine-specific coded instructions, ensuring that the CNC machines can execute operations accurately. Industry data suggests that using appropriate post processors can reduce setup times by approximately 30%, further enhancing productivity. By understanding the unique features and programming requirements of your equipment, operators can leverage these tools to unlock their machines' full potential, leading to improved output quality and reduced operational costs.

10 Essential Tips for Maximizing Efficiency with Your CNC Lathe and Milling Machine

| Tip Number | Tip Description | Expected Outcome |

|---|---|---|

| 1 | Understand Machine Capabilities | Increased productivity through optimized use of machine features |

| 2 | Proper Tool Selection | Reduced wear and tear, enhanced cutting efficiency |

| 3 | Regular Maintenance | Minimized downtime and prolonged machine lifespan |

| 4 | Optimize Cutting Parameters | Improved surface finish and reduced cycle time |

| 5 | Utilize CAM Software | Enhanced programming efficiency and precision |

| 6 | Stay Updated on Technology | Access to advanced features and better processing capabilities |

| 7 | Effective Workflow Design | Streamlined operations and reduced waste |

| 8 | Implement Quality Control | Higher quality outputs and less rework required |

| 9 | Train Your Operators | Increased operational efficiency and safer working environment |

| 10 | Monitor Performance Metrics | Data-driven decisions for continuous improvement |

Optimizing Tool Selection for Enhanced Machining Performance

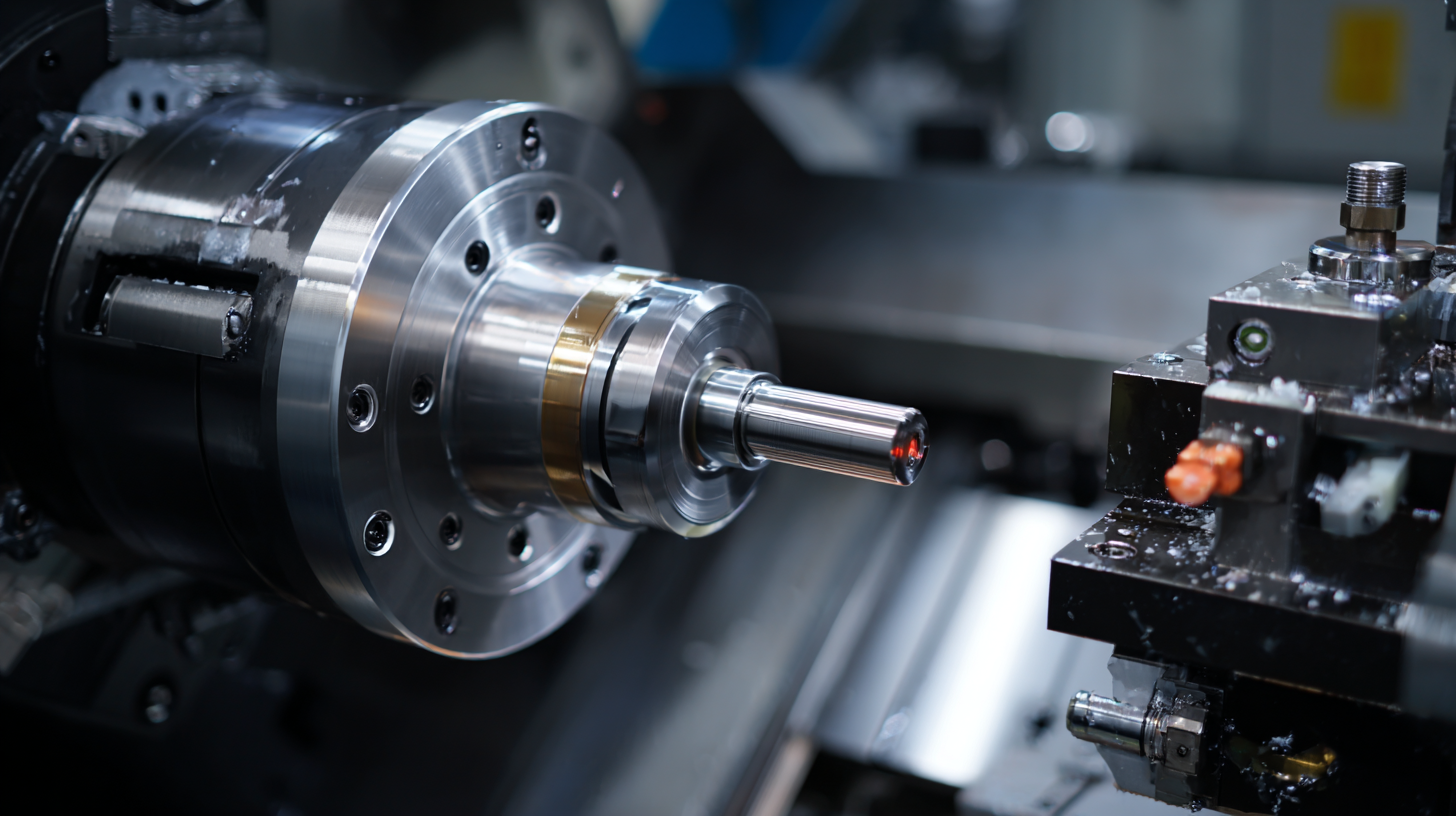

When it comes to enhancing machining performance with your CNC lathe and milling machine, optimizing tool selection is paramount. The right tooling can make a significant difference not only in the quality of your finished product but also in the efficiency of your operations. Begin by assessing the materials you will be working with, as different materials require specific tool geometries and coatings to achieve optimal cutting performance. For instance, carbide tools are often recommended for machining harder materials due to their superior hardness and wear resistance.

In addition to material considerations, understanding the various types of cutting tools available, such as end mills and turning tools, will allow you to choose the most effective options for your specific tasks. Selecting the appropriate tool diameter, cutting speed, and feed rate can lead to reduced cycle times and improved surface finishes. Moreover, regularly maintaining and replacing worn tools is crucial to prevent subpar performance and ensure consistent output quality. By focusing on these aspects of tool selection, you can significantly elevate the efficiency and productivity of your CNC machining operations.

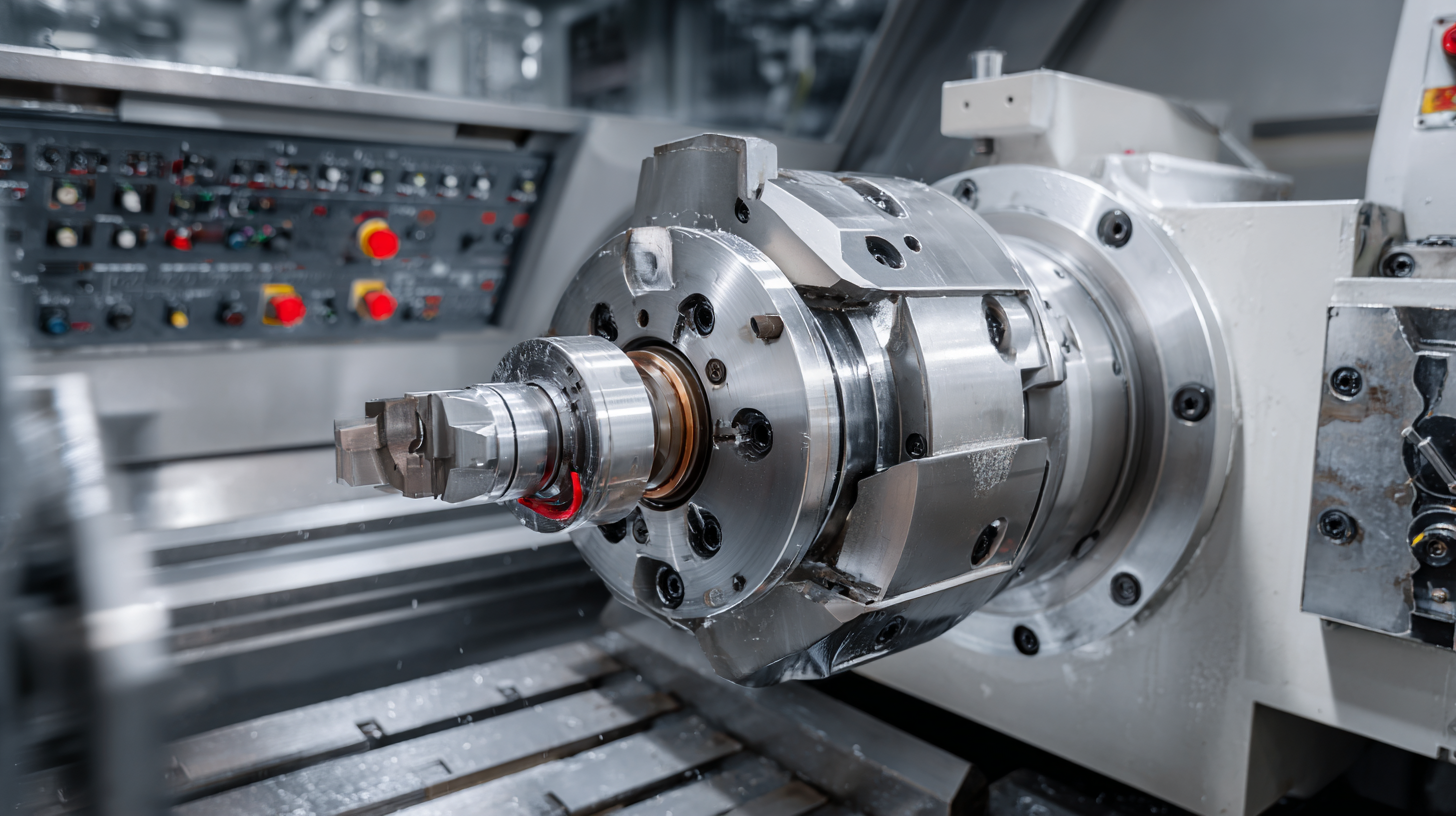

Implementing Effective Maintenance Routines for Longevity

Implementing effective maintenance routines is crucial for ensuring the longevity and efficiency of your CNC lathe and milling machine. Regular maintenance not only helps in identifying potential issues before they escalate into costly repairs but also enhances the overall performance of your equipment. Establishing a scheduled maintenance plan, which includes routine inspections, cleaning, and lubrication, can significantly reduce downtime and improve productivity. Monitoring critical components such as bearings, belts, and motors will provide insights into wear and tear, allowing for timely replacements and adjustments.

In addition to routine checks, it's important to educate operators on the best practices for using the machines. Proper training can prevent mishandling and excessive wear, ultimately extending the lifespan of your CNC equipment. Incorporating digital tools to track maintenance history and performance metrics can help streamline your processes, making it easier to predict future maintenance needs. By fostering a culture of proactive care and attention to detail, you can ensure that your machines operate at peak efficiency, driving down costs and increasing output over time.

Efficiency Metrics of CNC Lathe and Milling Machine Maintenance

Utilizing Software Solutions for Precision and Efficiency

Utilizing software solutions is a game-changer for achieving precision and efficiency in CNC lathe and milling operations. The integration of advanced software can streamline the entire machining process, minimizing human errors and enhancing productivity. From CAD/CAM systems that allow for intricate design and simulation to real-time monitoring software, these tools equip machinists with the ability to plan, execute, and analyze their work with unparalleled accuracy. Adopting such software not only simplifies complex tasks but also ensures that every cut and detail is optimized for the best possible outcome.

In addition to design and simulation, software solutions facilitate improved communication and data management on the shop floor. Many modern CNC machines come with built-in software that can communicate directly with enterprise resource planning (ERP) systems, enabling seamless tracking of materials, production schedules, and machine performance. This connectivity helps in making informed decisions, reducing downtime, and adjusting workflows to enhance overall operational efficiency. By leveraging these software tools, organizations can transform their CNC operations into a more agile and responsive environment, ultimately leading to higher quality output and increased customer satisfaction.

Adopting Best Practices for Workflow Management in the Shop

Maximizing efficiency in a machine shop requires a keen focus on workflow management. Implementing best practices can lead to significant improvements, as studies show that optimizing workflow can increase productivity by as much as 30% (Industry Week, 2020). One essential tip is to organize your workspace. By ensuring that tools and materials are easily accessible, operators can reduce setup times and enhance operational flow.

Another critical aspect is effective scheduling. Data from the Association for Manufacturing Technology reveals that better scheduling can reduce idle machine time by up to 25%. Incorporating advanced software solutions for job scheduling helps in aligning workloads with machine capabilities. Additionally, consider cross-training employees. This increases flexibility in staffing and ensures that the workflow remains uninterrupted even when there are staff shortages. By promoting a culture of collaboration and adaptability, shops can optimize their resources.

Regular maintenance of CNC lathes and milling machines is also vital for maintaining workflow efficiency. Scheduled maintenance can prevent costly downtime, leading to a reduction in lost production time. According to a report by the American National Standards Institute, routine maintenance can decrease breakdown incidents by up to 50%. Combining these practices will create a streamlined, efficient environment that can significantly enhance overall productivity in the shop.

Related Posts

-

Navigating the Future: 2025 Market Insights and How to Choose the Best Basic CNC Machine

-

Innovative Trends for Best CNC Machine Milling Machine in 2025 Shaping the Future of Manufacturing

-

Exploring the Future of Precision Manufacturing: Best CNC Lathe and Milling Machines for Global Buyers

-

Chinese Smart Manufacturing Leading the World with the Best Basic CNC Machine Quality Assurance

-

Innovative Solutions for Enhancing Precision with CNC Lathe and Milling Machine Technology

-

Navigating Global Trade: Understanding Import and Export Certifications for the Best Types of CNC Machines