How to Maximize Productivity with CNC Lathe Machine Techniques

In today's fast-paced manufacturing environment, maximizing productivity is crucial for staying competitive, and one of the key tools to achieve this is the CNC lathe machine. According to a report by the International Federation of Robotics, the use of CNC machining in production lines has increased efficiency by over 30% in recent years.

By implementing advanced techniques such as optimized tool paths, automated tool changers, and efficient spindle speed adjustments, facilities can significantly reduce cycle times and material waste.

Moreover, a study from the Association for Manufacturing Technology indicates that manufacturers who leverage CNC lathe machines effectively can achieve up to 50% reduction in operational costs.

This blog will explore practical strategies to enhance productivity using CNC lathe machines, providing insights that can help businesses harness their full potential in the evolving manufacturing landscape.

By implementing advanced techniques such as optimized tool paths, automated tool changers, and efficient spindle speed adjustments, facilities can significantly reduce cycle times and material waste.

Moreover, a study from the Association for Manufacturing Technology indicates that manufacturers who leverage CNC lathe machines effectively can achieve up to 50% reduction in operational costs.

This blog will explore practical strategies to enhance productivity using CNC lathe machines, providing insights that can help businesses harness their full potential in the evolving manufacturing landscape.

Understanding CNC Lathe Machines: Key Components and Functions

CNC lathe machines are pivotal in modern manufacturing, offering precision and efficiency. These machines transform raw materials into components with varying geometries, thanks to their key components: the spindle, tailstock, and tool post. The spindle rotates the workpiece at high speeds, allowing for intricate shaping and cutting.

According to a report from the International Federation of Robotics, CNC technologies have led to a productivity increase of over 30% in manufacturing sectors that utilize these machines.

CNC lathe machines are pivotal in modern manufacturing, offering precision and efficiency. These machines transform raw materials into components with varying geometries, thanks to their key components: the spindle, tailstock, and tool post. The spindle rotates the workpiece at high speeds, allowing for intricate shaping and cutting.

According to a report from the International Federation of Robotics, CNC technologies have led to a productivity increase of over 30% in manufacturing sectors that utilize these machines.

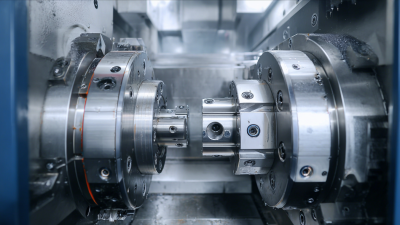

Understanding the functions of each component is essential for maximizing productivity. The tailstock aids in securing the workpiece and can also support tools for drilling operations, enhancing the versatility of the machine. Meanwhile, the tool post holds multiple cutting tools, enabling seamless transitions between operations. In a study published by the Manufacturing Institute, companies that employ advanced CNC machining saw a significant reduction in machine downtime, achieving an average operational efficiency improvement of 40%. By leveraging these key components and capabilities, manufacturers can significantly enhance their productivity and product quality in today’s competitive landscape.

Essential Techniques for Enhancing CNC Lathe Efficiency

Maximizing productivity in CNC lathe machining involves adopting essential techniques that enhance efficiency and output. One key approach is to optimize tool selection and maintenance. Ensuring that the right tools are available and regularly maintained can significantly reduce downtime, allowing for uninterrupted production cycles.

Furthermore, employing real-time monitoring technologies can help identify potential issues before they escalate, enabling proactive adjustments to keep operations running smoothly.

Another crucial technique is the implementation of advanced programming strategies, such as simulation software and adaptive control systems. These tools can streamline machining processes by predicting and adjusting for variations, ultimately improving precision and reducing waste. As highlighted in recent industry developments, the expansion of CNC machine capabilities, including integrated manufacturing systems, showcases the evolving landscape where efficiency loves innovation. By embracing these techniques, machinists can stay ahead in an increasingly competitive market.

Best Practices for Tool Setup and Maintenance on CNC Lathes

When it comes to maximizing productivity with CNC lathe machines, proper tool setup and maintenance are paramount. Effective tool setup begins with selecting the appropriate cutting tools for the specific materials and geometries being machined. Implementing precise tool setting techniques is essential, as it minimizes setup time and maximizes efficiency. It’s also crucial to consider the application of coolant directly to the cutting edge. This practice not only aids in heat management but also enhances chip evacuation and improves overall surface finish, contributing to higher quality outputs.

Maintenance of CNC lathes plays a critical role in sustaining productivity levels. Regular checks on tool wear and machine calibration ensure systems operate at peak performance. Moreover, embracing emerging technologies like digitalization, IoT, and AI can significantly streamline maintenance routines through predictive analytics. Such advancements help to foresee potential issues before they arise, reducing downtime and maintaining consistent production levels. Therefore, shops that prioritize both tool setup and maintenance, along with integrating cutting-edge technology, stand to gain a competitive advantage in today’s rapidly evolving manufacturing landscape.

Optimizing Workpieces: Strategies for Precision Machining

Maximizing productivity in precision machining requires a comprehensive strategy focused on optimizing workpieces. Recent trends indicate that advancements in CNC lathe techniques can significantly enhance efficiency and precision. For instance, implementing cutting-edge tooling technology has been shown to improve production rates by up to 30%, while also extending tool life and minimizing downtime. This is especially critical in today's competitive landscape, where manufacturers must adapt swiftly to changing demands and technological advancements.

**Tips for Optimizing Workpieces:**

1. **Employ Advanced Tooling:** Utilizing high-performance cutting tools can drastically reduce cycle times and improve surface finish quality. Invest in tools designed for specific materials to maximize efficiency.

2. **Regular Calibration:** Ensure your CNC lathe is calibrated regularly to maintain accuracy and precision. Even small deviations can lead to significant losses in quality and productivity.

3. **Data-Driven Decision Making:** Leverage data analytics to monitor machine performance and production metrics. Insights obtained can guide adjustments that optimize workflow and enhance overall productivity.

In light of recent innovations in the machining sector, continuous improvement in processes and technologies proves crucial. As the industry faces challenges such as supply chain disruptions, strategic investments in CNC lathes and precision tools can position manufacturers for long-term success.

Leveraging CNC Software for Workflow Automation and Analysis

In today's fast-paced manufacturing landscape, leveraging CNC software for workflow automation and analysis is essential for maximizing productivity. By integrating advanced CNC software solutions, businesses can significantly streamline their operations, reduce manual intervention, and enhance precision. One of the key advantages of using automated software is its ability to minimize human error, ensuring that each machining process is executed with consistent quality and accuracy.

Additionally, effective CNC software can facilitate real-time data analysis, allowing manufacturers to monitor performance metrics and adjust parameters on-the-fly. This capability not only helps in identifying bottlenecks in the production process but also enables predictive maintenance, reducing downtime and increasing overall efficiency.

As the CNC machine market continues to expand—projected to reach $195.59 billion by 2032—investing in cutting-edge software solutions becomes increasingly vital for businesses striving to stay competitive and responsive to market demands. Embracing these technologies can transform how companies operate, driving significant improvements in productivity and profitability.

Related Posts

-

Discover the Unique Features of Best CNC Lathe Machines and How to Choose the Right One

-

Ultimate Guide to Selecting the Best CNC Lathe Machine for Your Business Needs

-

Unveiling the Specifications: The Ultimate Guide to the Best CNC Lathe Machine for Global Buyers

-

Exploring the Future of Precision Manufacturing: Best CNC Lathe and Milling Machines for Global Buyers

-

Innovative Solutions for Enhancing Precision with CNC Lathe and Milling Machine Technology

-

2024 Ultimate Guide to Best Mill Turn Machines for Global Buyers