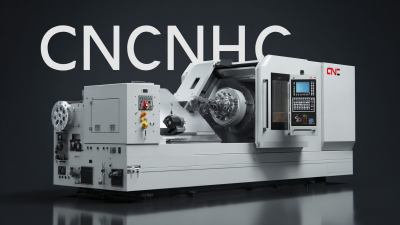

Innovative Solutions for Enhancing Precision with CNC Lathe and Milling Machine Technology

In the ever-evolving landscape of manufacturing, the integration of advanced technology has become paramount for achieving precision and efficiency. This blog delves into the innovative solutions that enhance the capabilities of CNC lathe and CNC milling machines, two pivotal tools in modern machining processes. By employing cutting-edge techniques and technologies, manufacturers are not only improving precision but also optimizing production times and reducing waste. In this comparison-focused discussion, we will explore various strategies, technologies, and best practices that drive improvements in CNC lathe and milling machine performance. With a growing demand for high-quality components across diverse industries, understanding these advancements is crucial for professionals seeking to elevate their machining operations to meet the challenges of the future.

Innovative Software Solutions for Real-Time CNC Machine Monitoring and Analysis

In today’s fast-paced manufacturing environment, real-time monitoring and analysis of CNC machines have become crucial for maximizing efficiency and precision. Innovative software solutions now allow operators to track performance metrics, detect anomalies, and predict maintenance needs, all in real-time. This instant data access empowers manufacturers to make informed decisions that can drastically reduce downtime and enhance overall productivity.

Advanced software tools integrate seamlessly with CNC lathe and milling machines, providing visual dashboards that display critical information at a glance. These dashboards can track parameters such as tool wear, spindle speed, and temperature, offering insights that lead to optimized machining processes. Furthermore, leveraging data analytics enables the identification of patterns that help refine operations and improve product quality. As the manufacturing landscape evolves, embracing these innovative software solutions will be imperative for staying competitive and achieving operational excellence.

Innovative Solutions for Enhancing Precision with CNC Lathe and Milling Machine Technology - Innovative Software Solutions for Real-Time CNC Machine Monitoring and Analysis

| Machine Type | Monitoring Software | Precision Level (%) | Real-Time Data Updates (seconds) | User Interface Rating (1-5) |

|---|---|---|---|---|

| CNC Lathe | LatheMonitor Pro | 99.5 | 5 | 4 |

| CNC Milling Machine | MillMaster Analytics | 98.9 | 3 | 5 |

| CNC Lathe | CNC Insight | 97.2 | 4 | 3 |

| CNC Milling Machine | MillingMax Suite | 99.0 | 2 | 4 |

| CNC Lathe | TurnTrack 360 | 96.5 | 6 | 3 |

Leveraging AI and Machine Learning for Enhanced CNC Lathe Precision

The advancement of AI and machine learning technologies is significantly transforming the CNC lathe and milling machine landscape. As these technologies are integrated, they empower manufacturers to enhance precision in machining operations, leading to improved product quality and efficiency. Current estimates project that the global CNC machine market will see substantial growth, from $101.22 billion in 2025 to $195.59 billion by 2032, driven largely by the increasing adoption of automation in manufacturing processes.

To fully leverage these advancements, manufacturers should focus on adopting AI-driven algorithms that can analyze real-time data. This allows for continuous adjustments during the machining process, significantly reducing errors and waste. Additionally, investing in training programs for employees to understand these technologies is crucial. By creating a workforce adept in both CNC technology and AI applications, companies can ensure they remain competitive in the evolving market.

Emphasizing precision is not only beneficial for operational efficiency but also enhances product development timelines. Implementing smart sensors that feed data back to the CNC machines can help monitor tool wear and predict maintenance needs, ensuring machines operate at peak performance. This proactive approach can lead to substantial cost savings and a reduction in downtime, reinforcing the importance of innovation in the manufacturing sector.

Optimizing Tool Path Strategies to Minimize Cycle Times and Improve Accuracy

The optimization of tool path strategies in CNC lathe and milling machine operations plays a crucial role in minimizing cycle times and enhancing accuracy. According to a market report by Technavio, the global CNC machine tools market is expected to grow by over $7 billion between 2021 and 2025. This growth is driven by advancements in machining technologies, which highlight the importance of efficient tool path strategies that allow manufacturers to stay competitive.

Implementing innovative algorithms such as adaptive tool path generation and predictive modeling can significantly reduce machining time while increasing precision. A study published in the International Journal of Advanced Manufacturing Technology indicated that employing optimized tool paths can reduce cycle times by up to 30%. Such innovations not only improve operational efficiency but also minimize material waste, reinforcing the economic sustainability of CNC operations. As the industry moves toward Industry 4.0, companies embracing these technological enhancements will likely see improved performance metrics, aligning with the ongoing trend towards automation and precision fabrication.

Implementing IoT in CNC Machining for Predictive Maintenance and Downtime Reduction

The integration of the Internet of Things (IoT) in CNC machining represents a significant advancement in the manufacturing industry. By embedding smart sensors and devices into CNC lathe and milling machines, manufacturers can achieve real-time monitoring of equipment performance. This technology enables the collection of valuable data that can be analyzed to predict potential machine failures before they occur. As a result, companies can implement predictive maintenance strategies, ensuring that machinery is serviced at optimal times, thereby minimizing unexpected downtimes.

Moreover, IoT implementation enhances overall operational efficiency by facilitating better decision-making through data-driven insights. Manufacturers can identify patterns in machine usage and wear, allowing them to optimize production schedules and maintenance routines. This proactive approach not only reduces costs associated with emergency repairs but also extends the lifespan of the machinery. As industries continue to embrace digital transformation, the synergy between IoT and CNC machining will play a crucial role in elevating precision, reliability, and productivity in modern manufacturing processes.

CNC Machining Precision Enhancement Over Years

This chart illustrates the improvement in machining precision over the years with the implementation of IoT for predictive maintenance.

The Role of Advanced Materials in Increasing CNC Machining Efficiency and Product Quality

The integration of advanced materials in CNC machining has revolutionized the capabilities of CNC lathe and milling machines, significantly enhancing efficiency and product quality. According to a report by MarketsandMarkets, the global advanced materials market is expected to grow from $75.2 billion in 2020 to $109.9 billion by 2025, driven by innovations in industries that demand high precision and durability. Materials such as titanium alloys and carbon fiber composites not only reduce the weight of machined components but also increase their resistance to wear and corrosion, allowing CNC machines to operate at higher speeds and with greater accuracy.

Furthermore, the use of advanced materials contributes to a reduction in production costs. A study by the NIST highlighted that incorporating advanced materials can lead to a 20% increase in machining efficiency, thanks to their superior machinability and longer lifespan. This efficiency translates into less downtime and lower maintenance costs, enabling manufacturers to meet the growing demands for precision components in various sectors, including aerospace, automotive, and medical devices. As such, the adoption of advanced materials is essential for businesses looking to enhance their competitive edge in the fast-evolving manufacturing landscape.

Related Posts

-

Navigating the Future: 2025 Market Insights and How to Choose the Best Basic CNC Machine

-

Innovative Trends for Best CNC Machine Milling Machine in 2025 Shaping the Future of Manufacturing

-

Top Strategies for Choosing the Best CNC Milling Machine for Your Business Needs

-

Unveiling the Specifications: The Ultimate Guide to the Best CNC Lathe Machine for Global Buyers

-

Chinese Smart Manufacturing Leading the World with the Best Basic CNC Machine Quality Assurance

-

Discover How Top Chinese Factories Redefine Excellence in Precision CNC Milling Machines