Innovative Solutions for Effective Use of Best Types of CNC Machines

In the rapidly evolving landscape of modern manufacturing, the effective utilization of various types of CNC machines has become crucial for achieving operational excellence. According to a report by MarketsandMarkets, the CNC market is projected to reach USD 105.89 billion by 2026, growing at a CAGR of 6.0% from 2021. This growth underscores the rising demand for precision, efficiency, and adaptability that CNC machines offer. As industries across the globe strive for innovation, understanding the best types of CNC machines and integrating them effectively into production lines can significantly boost productivity and enhance product quality. In this blog, we will explore innovative solutions that cater to the diverse needs of manufacturers, highlighting how excellence in manufacturing, rooted in China's strengths, can lead to global service excellence.

Exploring Cutting-Edge CNC Machine Technologies for Global Manufacturing Leadership

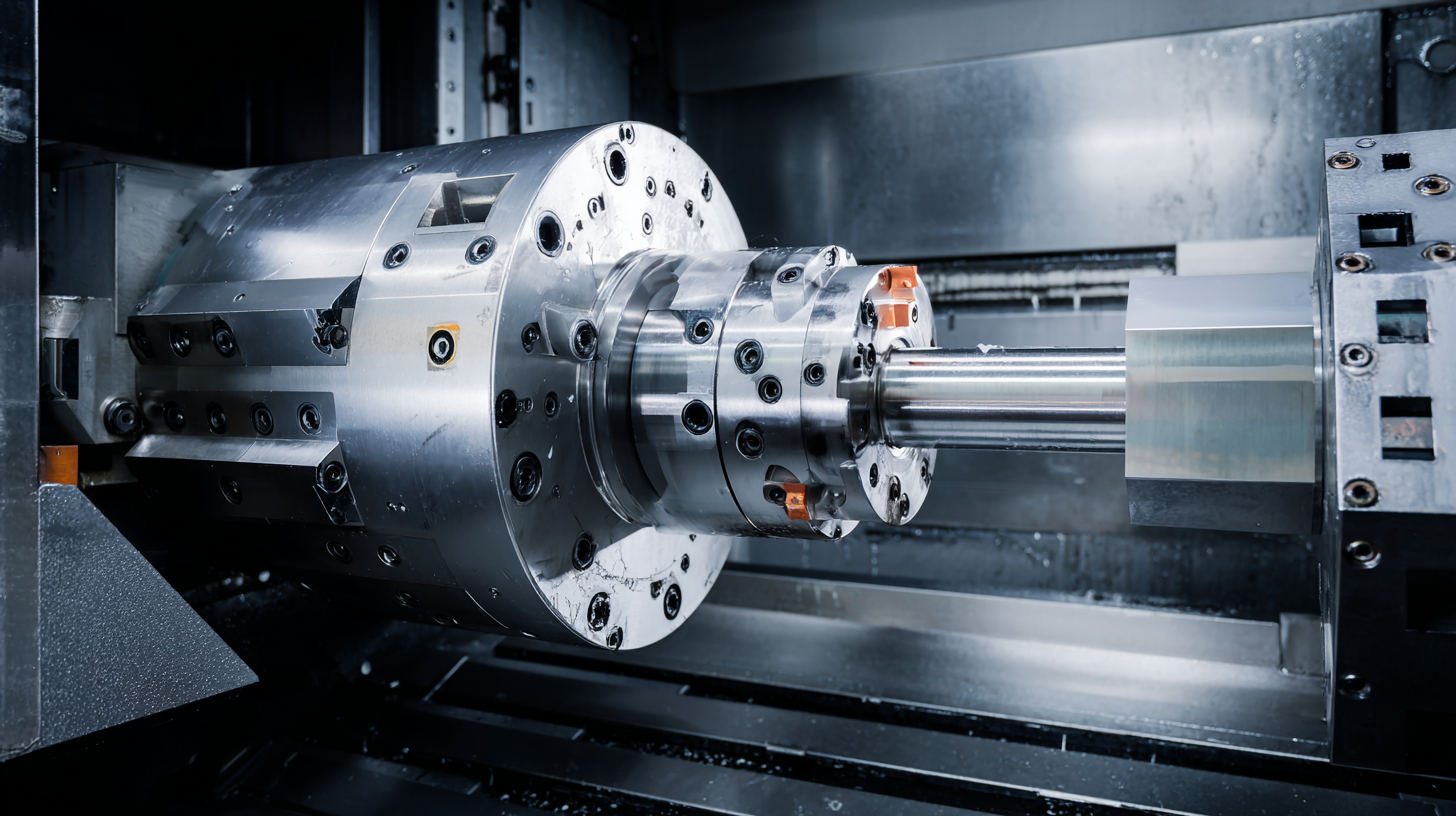

As industries worldwide strive for greater efficiency and precision, cutting-edge CNC (Computer Numerical Control) machine technologies have emerged as critical enablers for manufacturing leadership. These innovative solutions not only enhance production capabilities but also allow companies to maintain a competitive edge in a rapidly evolving marketplace. From advanced multi-axis machines that facilitate complex geometries to automated tool changers that minimize downtime, the latest CNC technologies are redefining the operational landscape for manufacturers.

The integration of smart technologies, such as IoT (Internet of Things) and AI (Artificial Intelligence), is further revolutionizing CNC machining. These technologies allow for real-time monitoring and predictive maintenance, leading to improved productivity and reduced operational costs. By leveraging data analytics, manufacturers can optimize their processes and make informed decisions, positioning themselves at the forefront of global manufacturing innovation. As we delve deeper into these advancements, it becomes clear that embracing the best types of CNC machines is not just a trend but a necessity for those aiming to lead in a fiercely competitive global environment.

Innovative Solutions for Effective Use of Best Types of CNC Machines

| CNC Machine Type | Cutting Technology | Max Speed (RPM) | Precision (Microns) | Applications |

|---|---|---|---|---|

| Milling Machine | End Mill Cutting | 10000 | 5 | Aerospace, Automotive |

| Laser Cutter | CO2 Laser Cutting | 20000 | 10 | Metal Fabrication, Signage |

| Plasma Cutter | Plasma Arc Cutting | 15000 | 20 | Shipbuilding, Construction |

| Water Jet Cutter | High Pressure Water Jet | 5000 | 25 | Stone, Glass, Metal |

| EDM Machine | Wire EDM | 1200 | 1 | Tooling, Molds |

Maximizing Efficiency: Key Strategies for Optimal CNC Machine Utilization

Maximizing efficiency in CNC machine utilization requires a strategic approach that integrates both advanced tools and thoughtful operational practices. One significant method of achieving this is through the adoption of automatic nesting tools, which substantially reduce raw material wastage during cutting processes. By optimizing the layout of parts to be cut from large sheets of material, these tools ensure that every inch is utilized effectively, resulting in cost savings and a decreased environmental footprint.

Moreover, employing high-speed milling techniques can further enhance manufacturing efficiency. Utilizing multi-flute, solid-carbide end mills coupled with advanced machining strategies not only boosts Material Removal Rate (MRR) in challenging materials like titanium and Inconel but also improves overall production timelines. Such strategies not only streamline the machining process but also extend tool life and reduce wear, contributing to a more sustainable manufacturing operation. By prioritizing these innovative solutions, manufacturers can maximize output while minimizing waste, ultimately leading to a more profitable and eco-friendly production environment.

The Role of Automation in Revolutionizing CNC Machining Processes

The integration of automation in CNC machining is transforming the manufacturing landscape, enabling businesses to achieve unparalleled precision and efficiency. With the advent of advanced robotics and AI, CNC machines are now equipped with predictive maintenance capabilities and automated programming. This revolution allows manufacturers to minimize downtime, adapt quickly to design changes, and optimize production processes seamlessly. By leveraging these automated systems, companies can create more intricate designs with higher fidelity, thus meeting the rising demands of rapid prototyping and custom production.

Moreover, the emergence of collaborative robots, or cobots, enhances the flexibility of CNC machining environments. These innovative machines work alongside human operators, providing augmented support that increases reliability while reducing the risk of human error. The synergy between automation and skilled labor results in a harmonious workflow that not only boosts productivity but also elevates the level of craftsmanship in production. As automation continues to shape the future of CNC machining, manufacturers are poised to gain a competitive edge in a rapidly evolving marketplace.

Comparison of Different CNC Machine Types: Which One Suits Your Needs?

When it comes to selecting the right CNC machine for your projects, understanding the different types available is crucial. CNC machining encompasses various styles, including CNC mills, lathes, routers, and plasma cutters, each designed for specific tasks.

CNC mills, for instance, excel in producing complex shapes with high precision, making them ideal for intricate component manufacturing. Meanwhile, CNC lathes are perfect for turning processes, allowing you to create cylindrical parts with a smooth finish.

Choosing the most suitable CNC machine for your needs involves evaluating your project requirements and material types. If your work involves woodworking, a CNC router might be your best bet due to its ability to handle softer materials and create intricate designs. For metalwork, a CNC plasma cutter offers distinct advantages by providing speedy cuts and the ability to work with thicker materials. Ultimately, understanding these differences will enable you to make an informed decision, ensuring that your CNC machine selection aligns with your operational goals and boosts productivity.

Case Studies: Successful Implementation of CNC Solutions in Leading Factories

The integration of CNC machines in manufacturing has become a game-changer, significantly enhancing productivity across multiple sectors. Successful case studies from leading factories illustrate this impact clearly. For instance, companies embracing CNC solutions have reported an average productivity increase of 20-30%, thanks to streamlined operations and reduced manual errors. In industries such as automotive and aerospace, the precision offered by advanced CNC machines ensures superior quality control, crucial for meeting demanding regulatory standards.

Tip: To maximize the benefits of CNC implementation, focus on employee training and development. A well-trained workforce can leverage the full potential of these machines, leading to decreased downtime and enhanced efficiency.

China’s rapid emergence as a leader in advanced manufacturing highlights the crucial role of innovation within its factories. With universities and research institutions driving the development of cutting-edge technologies, Chinese manufacturers are increasingly utilizing IoT systems to connect and optimize CNC operations. This convergence results in a complete digital ecosystem that not only boosts productivity but also enhances overall equipment effectiveness (OEE) by integrating Total Productive Maintenance (TPM) practices.

Tip: Regularly assess and update your manufacturing processes. Implementing a continuous improvement culture can significantly enhance your CNC machine's performance and adaptability in a fast-evolving industrial landscape.