The Future of Innovative Aluminium Milling Machines in Global Manufacturing

As the global manufacturing landscape continues to evolve, the significance of advanced machinery is increasingly apparent, particularly with regards to aluminium milling machines. According to a recent report by MarketsandMarkets, the global aluminium machining market is projected to reach USD 11.57 billion by 2026, driven by the rising demand for lightweight materials in industries such as automotive and aerospace.

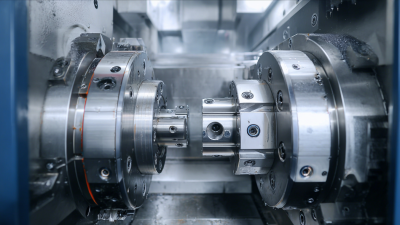

Aluminium milling machines play a crucial role in this growth, offering precision, efficiency, and versatility for milling complex components. Moreover, the shift towards automation and Industry 4.0 practices has further ignited interest in innovative milling technologies, paving the way for smarter, more efficient manufacturing processes. This ultimate guide will explore the future of aluminium milling machines, highlighting key trends, technological advancements, and the overarching impact they will have on global manufacturing operations.

The Evolution of Aluminium Milling Machines in the Digital Age

The digital age is reshaping the landscape of aluminium milling machines, driving significant advancements in efficiency and precision. As manufacturing processes become increasingly digitized, the integration of smart technologies is a pivotal factor in enhancing operational productivity. According to a recent report by market analysts, the global demand for aluminium is projected to reach 80 million tons by 2025, reflecting a compound annual growth rate (CAGR) of 5.1%. This surge underscores the critical need for advanced milling machines that can meet growing production demands while adhering to stringent quality standards.

Innovative aluminium milling machines are now equipped with sophisticated features such as AI-driven automation, real-time monitoring systems, and enhanced user interfaces. These advancements not only streamline operations but also minimize waste and reduce lead times. For instance, the adoption of digital factories has demonstrated productivity enhancements of up to 25%, enabling firms like notable players in the aluminium sector to optimize resource allocation and improve overall manufacturing throughput. As the industry progresses towards greener practices, sustainable milling technologies are becoming essential, reinforcing the importance of innovation in maintaining competitiveness in the global market.

Key Innovations Shaping the Future of Aluminium Milling Technology

The aluminium milling technology landscape is rapidly evolving, driven by a series of key innovations that are reshaping global manufacturing. According to a report by Research and Markets, the global aluminium machining market is expected to grow at a CAGR of 5.6% from 2022 to 2027, indicating a strong demand for advanced milling machines. These machines are increasingly equipped with smart technologies, including IoT and AI, which enhance precision and reduce operational costs. Integration of data analytics allows for real-time monitoring and predictive maintenance, leading to less downtime and greater overall efficiency in production lines.

Another significant innovation is the advancement of multi-axis milling capabilities, which facilitate complex geometries and tighter tolerances crucial for industries such as aerospace and automotive. A report from Technavio projects that advancements in multi-axis technology will contribute significantly to a projected market growth of over $1 billion by 2025. Furthermore, the development of high-speed milling techniques and improved cutting tool materials, such as coated carbide and ceramic options, enhances the speed and quality of aluminium machining processes. These innovations not only meet the growing needs of manufacturers but also align with sustainability goals by reducing material waste and energy consumption.

The Future of Innovative Aluminium Milling Machines in Global Manufacturing

The Role of Automation and AI in Enhancing Milling Efficiency

In the realm of global manufacturing, the integration of

automation and

artificial intelligence (AI)

into aluminium milling machines is poised to revolutionize production efficiency.

Recent insights indicate that the automation in feed mill control systems can optimize

production processes, driving unprecedented levels of accuracy and output.

For instance, the

rice milling machine market

is projected to grow from

USD 1.2 billion in 2024,

with a compound annual growth rate (CAGR) exceeding

4.1% through 2034.

This growth is largely attributed to the rising demand for automated solutions that enhance

milling capabilities.

Furthermore, innovative technologies like

AI-powered grinding robots

are setting new benchmarks in the industry. The installation of such robotics not only

boosts precision but also significantly enhances operational efficiency in metal part production.

Predictive maintenance, fueled by AI, is reshaping the landscape

of feed mills by transforming them from reactive to proactive entities, thereby minimizing downtime

and reducing operational costs. As enterprises increasingly adopt

intelligent automation,

the potential for streamlined operations and improved production metrics continues to expand, marking

a pivotal shift in manufacturing paradigms.

Sustainability Trends in Aluminium Milling: A Global Perspective

The aluminium milling industry is witnessing a significant transformation driven by sustainability trends that align with global manufacturing goals. Recent reports indicate that the CNC metal cutting machine tools market is expanding, with a notable increase in demand as companies adopt advanced technologies to optimize resource use. Specifically, the global CNC router machine market is projected to grow at a CAGR of 3.5%, reaching an estimated value of USD 691 million by 2030. This growth reflects a broader commitment to sustainable manufacturing practices, where innovation in aluminium milling machines is pivotal.

Moreover, industry experts have identified a critical shift towards secondary aluminium production as a sustainable alternative that minimizes environmental impact. Technological advancements and digitalization in the aluminium sector are expected to play significant roles in achieving sustainability targets, especially in light of the challenges posed by global climate goals. With pressures from initiatives like the Paris Agreement, manufacturers are increasingly looking to enhance their processes through recycling and efficient resource management. This trend not only supports the circular economy but also positions the aluminium milling sector as a key player in the transition to sustainable manufacturing practices.

The Future of Innovative Aluminium Milling Machines in Global Manufacturing - Sustainability Trends in Aluminium Milling: A Global Perspective

| Region | Production Volume (Tons) | Growth Rate (%) | Sustainable Practices Implemented | Recycling Rate (%) | Energy Consumption (kWh/Ton) |

|---|---|---|---|---|---|

| North America | 1,200,000 | 4.5 | Use of renewable energy sources, waste minimization | 75 | 200 |

| Europe | 1,500,000 | 5.2 | Closed-loop production systems, eco-design | 85 | 180 |

| Asia-Pacific | 2,000,000 | 6.0 | Energy-efficient technologies, recycling initiatives | 65 | 220 |

| Latin America | 800,000 | 3.5 | Adoption of cleaner production methods | 55 | 250 |

| Middle East & Africa | 600,000 | 2.8 | Investments in resource-efficient technologies | 40 | 300 |

Challenges and Opportunities in the Aluminium Milling Industry Ahead

The aluminium milling industry is currently facing a complex landscape characterized by both significant challenges and unique opportunities. With the recent US tariffs affecting Vietnamese aluminium and steel exports, manufacturers in Vietnam, despite not being the largest exporters, must navigate a challenging environment that impacts cost structures and competitiveness. This situation highlights the necessity for companies to innovate in process efficiency and robotics to sustain their market position. Recent studies suggest a growing emphasis on high-precision and efficiency in robotic milling for complex parts, indicating that advancements in technology can help mitigate some of these challenges.

Moreover, the aluminium powder market is projected to experience a compound annual growth rate of approximately 4% from 2025 to 2034, reflecting a robust demand that presents opportunities for milling machine manufacturers. The exploration of advanced cutting tools and innovation in machining techniques will be paramount. For instance, the ongoing development in cutting technologies indicates a shift towards handling more challenging materials, which could redefine manufacturing standards. As seen in industry reports, the future of aluminium milling machines hinges not only on addressing current adversities, such as tariffs and toxic exposure, but also on embracing innovative solutions that fulfill the evolving demands of global manufacturing.

Related Posts

-

Unleashing Global Excellence in CNC Milling Machines with Premium Quality from China

-

Navigating the Future: 2025 Market Insights and How to Choose the Best Basic CNC Machine

-

Unlocking Innovation with the Best CNC Machine Milling Machine Options for Global Buyers

-

Top Strategies for Choosing the Best CNC Milling Machine for Your Business Needs

-

2024 Ultimate Guide to Best Mill Turn Machines for Global Buyers

-

Navigating Global Trade: Understanding Import and Export Certifications for the Best Types of CNC Machines