10 Digital Tips for Choosing the Perfect Micro CNC Milling Machine for Your Business Needs

In today's rapidly evolving manufacturing landscape, the demand for precision and efficiency has never been higher, leading to a significant rise in the popularity and use of micro CNC milling machines. According to a recent report by MarketsandMarkets, the global CNC machine market is projected to reach $117 billion by 2026, with micro CNC milling machines playing a crucial role in this growth due to their ability to produce intricate designs with minimal waste. These compact machines cater to various industries, including aerospace, medical, and electronics, where precision is paramount. As businesses seek to enhance their operational capabilities, understanding the key factors in choosing the perfect micro CNC milling machine becomes essential. This guide will provide valuable insights and digital tips that will aid manufacturers in making informed decisions tailored to their unique business needs.

Understanding Your Business Requirements for a Micro CNC Milling Machine

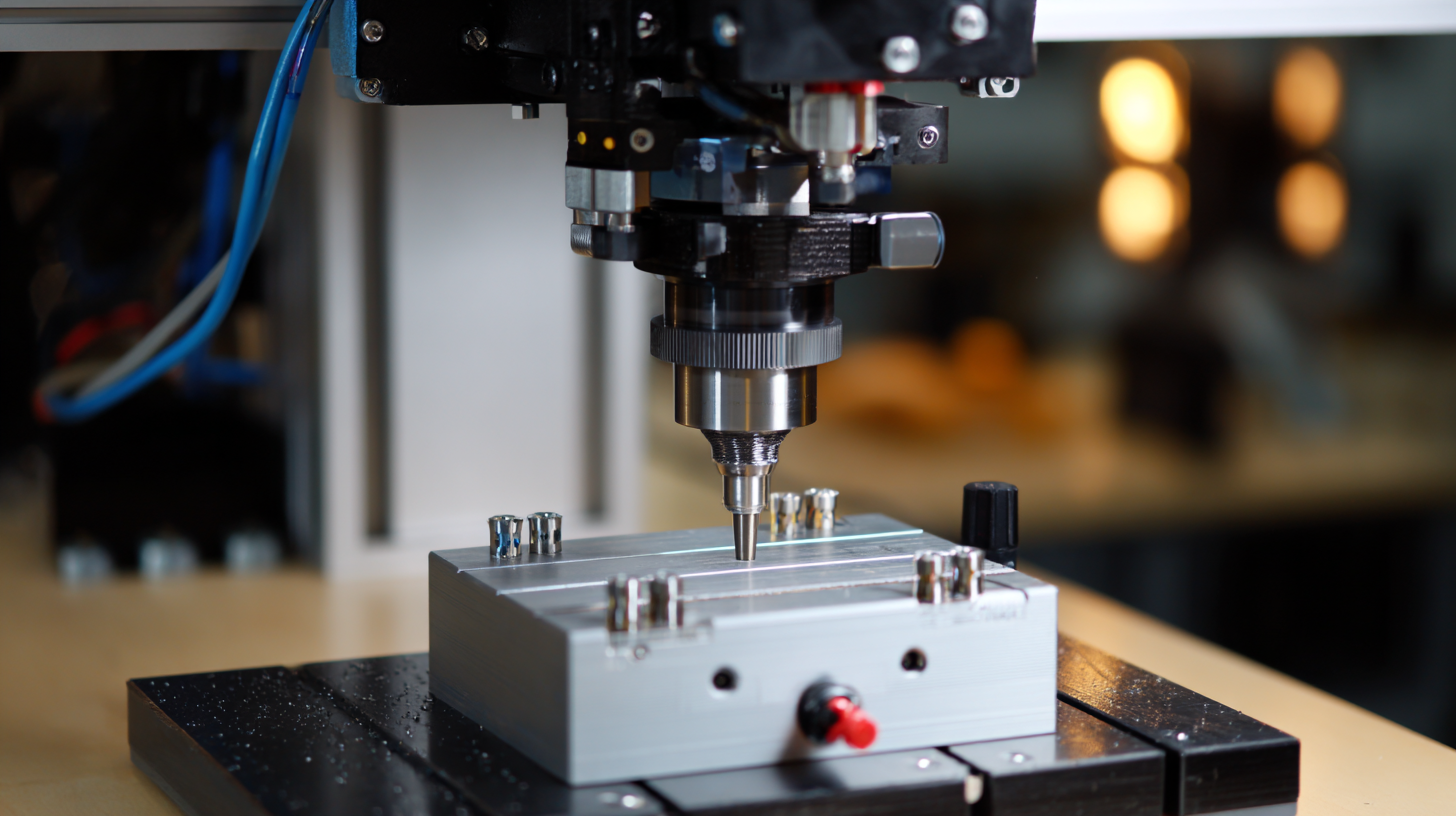

When considering the purchase of a micro CNC milling machine for your business, it’s crucial to start by thoroughly understanding your specific requirements. The type of materials you plan to work with, the complexity of the designs you aim to produce, and the volume of production are all critical factors that will influence your choice. For instance, if your business focuses on detailed prototypes or intricate parts, you may require a machine with higher precision and an advanced spindle speed. Conversely, a machine designed for bulk production may prioritize efficiency and durability over precision.

Another essential aspect to consider is the space and infrastructure available in your workspace. Micro CNC milling machines come in various sizes, and ensuring that your chosen model fits comfortably in your production area is key. Additionally, it's vital to assess your team’s skill level and training needs. A more sophisticated machine might offer advanced features but could also require more expertise to operate effectively. Thus, balancing the machine’s capabilities with your team’s proficiency will help you make an informed decision that aligns with your business goals.

Key Features to Look for in a Micro CNC Milling Machine

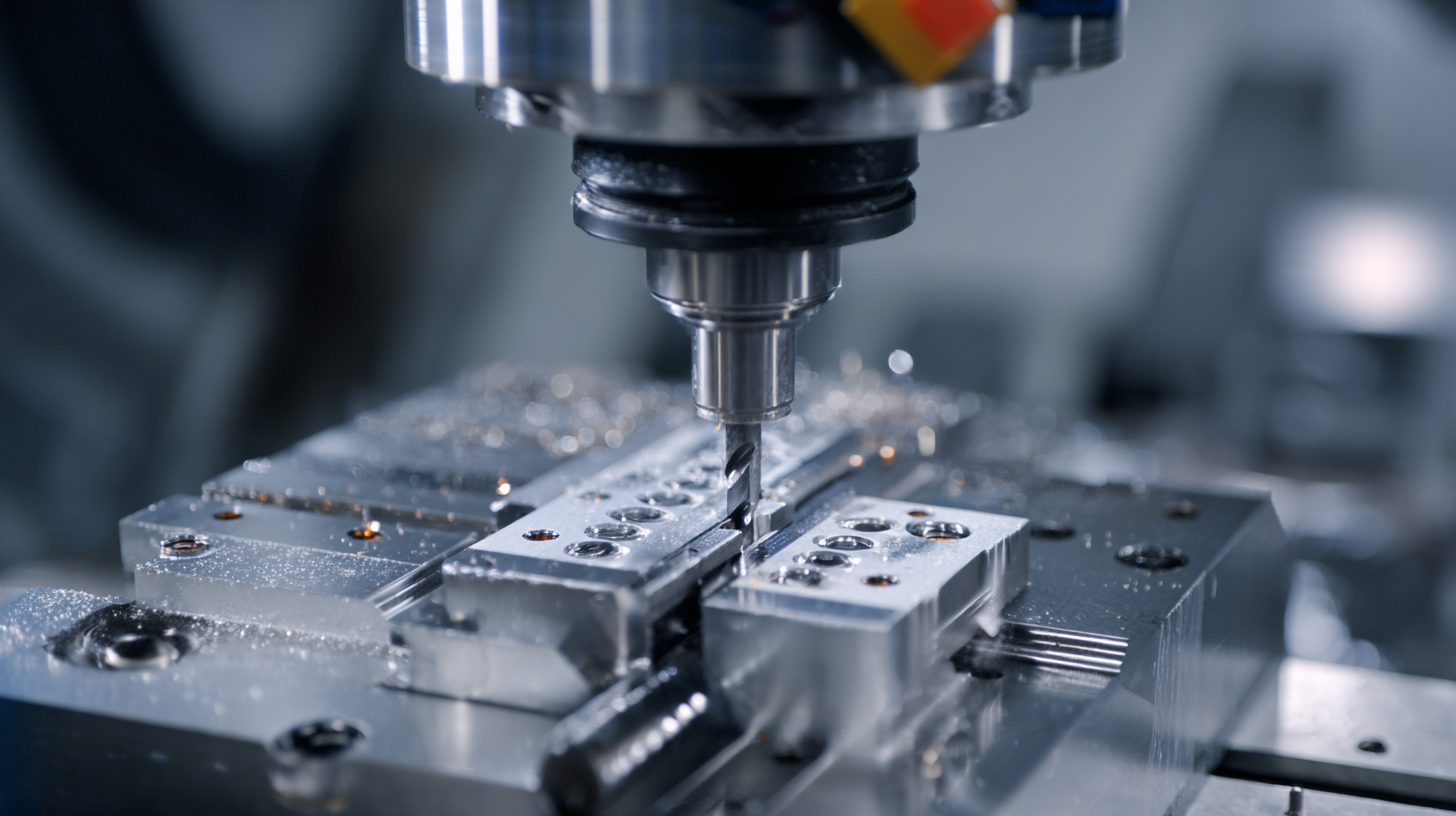

When selecting the perfect micro CNC milling machine for your business, it's essential to understand the key features that can significantly impact your machining processes. One crucial aspect to consider is the machine's rigidity and construction materials. A robust design ensures stability during operations, which translates to higher precision and better surface finishes. Look for machines that feature high-quality metal bodies and reinforced components to minimize vibrations.

Another vital feature is the control system used by the micro CNC milling machine. An intuitive and easy-to-use control interface can drastically reduce setup time and increase productivity. Advanced systems that include touchscreen capabilities and customizable software options can greatly enhance your machine’s usability, making it easier to program complex machining tasks.

Additionally, consider the range of compatible tools and accessories that your micro CNC milling machine supports. The versatility in tooling options allows for a broader range of materials and shapes to be processed, which is especially beneficial for businesses that require flexibility in their operations. Choosing a machine with an extensive selection of compatible tools ensures that you can adapt to your production needs over time.

Key Features of Micro CNC Milling Machines

This bar chart illustrates the importance of key features when choosing a micro CNC milling machine for business needs. The data reflects the percentage of businesses that prioritize each feature based on industry surveys.

Evaluating the Best Brands and Models for Your Needs

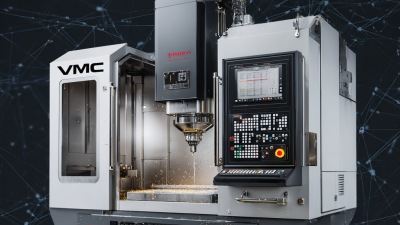

When selecting the perfect micro CNC milling machine for your business, it’s crucial to start by evaluating the best brands and models that align with your specific needs. Leading brands like Tormach, Haas, and Roland have established a reputation for delivering precision and reliability. Investigate the range of options available from these manufacturers, focusing on their unique features such as build quality, software compatibility, and ease of use. A model that excels in precision but lacks user support may hinder your operations, so make sure to consider the manufacturer's customer service reputation as well.

In addition to brand reputation, compare different models by assessing key specifications like spindle speed, feed rates, and the variety of materials they can handle. Detailed reviews from industry experts and user testimonials can provide invaluable insights into each model's performance. Pay attention to the versatility of the machine; a micro CNC milling machine that can accommodate various machining techniques will offer greater adaptability for your projects. By carefully weighing these factors, you can make an informed decision that leverages the strengths of the best brands and models tailored to your business objectives.

Budgeting for Your Micro CNC Milling Machine Purchase

When considering the purchase of a micro CNC milling machine, budgeting is a critical step that often determines the overall success of your investment. Recent industry studies indicate that micro CNC machines can range from $1,000 to over $10,000, depending on functionality and precision. According to a report by Research and Markets, the global CNC market is expected to reach $100 billion by 2028, highlighting the growing demand for advanced machining technologies that cater to small and medium-sized enterprises. Businesses need to assess their needs carefully, as sacrificing quality for a lower price can lead to increased long-term costs due to maintenance and production errors.

Incorporating a detailed budget means not only accounting for the initial cost of the machine but also considering ancillary costs such as tooling, software, and training. A study published by the National Institute of Standards and Technology (NIST) emphasizes that equipment costs can represent up to 35% of total operational expenses in manufacturing. Therefore, while a lower-priced model might seem appealing, it's essential to evaluate the total cost of ownership to ensure that your micro CNC milling machine serves your business needs effectively and contributes to your bottom line.

10 Digital Tips for Choosing the Perfect Micro CNC Milling Machine for Your Business Needs - Budgeting for Your Micro CNC Milling Machine Purchase

| Feature | Specification | Price Range ($) | Best Use Case |

|---|---|---|---|

| Cutting Area | 200 x 200 x 150 mm | $1,200 - $1,800 | Small Parts Production |

| Spindle Speed | 40,000 RPM | $1,500 - $2,200 | High Precision Machining |

| Material Compatibility | Aluminum, Plastics, Wood | $1,000 - $2,500 | Versatile Applications |

| Control System | CNC Software Compatible | $800 - $1,600 | Complex Designs |

| Power Requirement | 220V | $1,000 - $2,000 | Standard Industrial Use |

Maintenance Tips for Longevity and Performance of Your Micro CNC Milling Machine

When investing in a micro CNC milling machine, maintenance is key to ensuring longevity and optimal performance. Regular cleaning of the machine components is essential; dust and debris can accumulate, affecting precision and efficiency. Utilize compressed air to blow away chips and particles, and wipe down surfaces with appropriate cleaning agents to avoid corrosion and wear. Establishing a consistent cleaning routine can significantly prolong the lifespan of your equipment.

Lubrication is another critical aspect of maintenance that should not be overlooked. Regularly check the lubrication levels of all moving parts, including the spindle and linear guides. Using the manufacturer-recommended lubricants will prevent friction and overheating, ensuring smooth operation. Additionally, it’s important to inspect the machine for any signs of wear or misalignment. Early detection of issues can save time and costly repairs down the line, allowing your business to maintain optimal productivity. By prioritizing these maintenance tips, you can enhance the performance of your micro CNC milling machine and ensure it serves your business needs effectively for years to come.

Related Posts

-

Innovative Trends for Best CNC Machine Milling Machine in 2025 Shaping the Future of Manufacturing

-

Unleashing Global Excellence in CNC Milling Machines with Premium Quality from China

-

Top Strategies for Choosing the Best CNC Milling Machine for Your Business Needs

-

Innovative Solutions for Enhancing Precision with CNC Lathe and Milling Machine Technology

-

Solutions for Selecting the Best VMC Milling Machine for Your Manufacturing Needs

-

Ultimate Guide to Selecting the Best CNC Lathe Machine for Your Business Needs