Unlocking Precision: How CNC Milling Machines Revolutionize Modern Manufacturing

In the landscape of modern manufacturing, the advent of advanced technologies has paved the way for unprecedented precision and efficiency. Among these technological marvels, the CNC milling machine stands out as a pivotal innovation, transforming traditional production methods into streamlined processes characterized by accuracy and speed. By automating various milling operations, CNC milling machines not only enhance the quality of the finished products but also significantly reduce the margin for human error. This evolution in manufacturing techniques prompts the question: why are CNC milling machines essential in today’s industrial arena? As we delve into the mechanics and benefits of these machines, we will explore how they are not just tools for cutting and shaping materials but rather key enablers of growth, adaptability, and competitiveness in an increasingly demanding market.

In the landscape of modern manufacturing, the advent of advanced technologies has paved the way for unprecedented precision and efficiency. Among these technological marvels, the CNC milling machine stands out as a pivotal innovation, transforming traditional production methods into streamlined processes characterized by accuracy and speed. By automating various milling operations, CNC milling machines not only enhance the quality of the finished products but also significantly reduce the margin for human error. This evolution in manufacturing techniques prompts the question: why are CNC milling machines essential in today’s industrial arena? As we delve into the mechanics and benefits of these machines, we will explore how they are not just tools for cutting and shaping materials but rather key enablers of growth, adaptability, and competitiveness in an increasingly demanding market.

The Evolution of CNC Milling: From Traditional Methods to Advanced Automation

The evolution of CNC milling technology marks a significant shift from traditional manufacturing methods to advanced automated processes. As the global CNC machine market is projected to grow from $101.22 billion in 2025 to $195.59 billion by 2032, with a CAGR of 9.9%, it is clear that industries are increasingly embracing automation and precision. This transition is being further accelerated by the integration of artificial intelligence in CNC machining, transforming traditional paradigms and enhancing overall efficiency and accuracy.

Tips: When investing in CNC technology, consider the scalability of the machinery. This not only allows for adaptability to evolving manufacturing needs but also ensures long-term value. Additionally, prioritize machines with advanced automation features to streamline production processes and minimize human error.

The milling machine market, specifically, is expected to reach approximately $116,722.7 million by 2035, driven primarily by advancements in CNC technology and smart automation systems. This growth highlights the critical role that CNC milling plays in meeting the demands for high-precision parts across various sectors. Embracing these advancements can significantly improve manufacturing capabilities and reduce lead times.

Unlocking Precision: How CNC Milling Machines Revolutionize Modern Manufacturing

| Aspect | Traditional Methods | CNC Milling Machines | Benefits of CNC |

|---|---|---|---|

| Precision | Low | High | Enhanced product quality |

| Production Speed | Slow | Fast | Increased efficiency |

| Labor Requirement | High | Low | Reduced labor costs |

| Flexibility | Limited | High | Ability to handle complex designs |

| Setup Time | Long | Short | Quicker project turnaround |

| Maintenance | Manual | Automated | Lower risk of errors |

Key Metrics: The Impact of CNC Milling on Production Efficiency and Cost Reduction

CNC milling machines have fundamentally transformed the landscape of modern manufacturing by significantly enhancing production efficiency and reducing costs. By leveraging precise computer-controlled operations, these machines minimize material waste and optimize cutting processes. This level of accuracy allows manufacturers to produce complex components with minimal human intervention, leading to a remarkable decrease in labor costs and time spent on manual setups.

Moreover, CNC milling contributes to improved production efficiency through faster turnaround times and consistent quality. With the ability to run unattended for extended periods, these machines can operate around the clock, greatly increasing output without sacrificing precision. The integration of advanced software for design and programming further streamlines operations, enabling manufacturers to respond swiftly to market demands. Ultimately, the strategic adoption of CNC milling not only elevates productivity but also plays a crucial role in maintaining competitive pricing in an ever-evolving industrial landscape.

Unlocking Precision: The Impact of CNC Milling on Production Efficiency and Cost Reduction

This bar chart illustrates the impact of CNC milling machines on production efficiency, which achieves an impressive 85% improvement, and cost reduction, which results in a decrease of 30%. These metrics highlight the transformative role of CNC technology in modern manufacturing contexts.

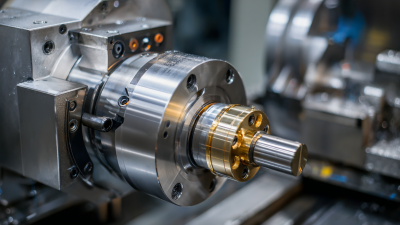

Precision Engineering: How CNC Milling Machines Achieve Tolerances of ±0.001 Inches

CNC milling machines are transforming the landscape of modern manufacturing by achieving remarkable precision in engineering. With tolerances of ±0.001 inches, these machines enable manufacturers to produce intricate parts with accuracy that was once thought unattainable. This level of precision is critical in industries such as aerospace, medical devices, and automotive, where even the smallest deviation can lead to significant failures. The combination of advanced software and high-quality cutting tools allows CNC milling to maintain these tight tolerances while improving efficiency and reducing waste.

Tip: To optimize the performance of CNC milling machines, manufacturers should regularly calibrate equipment and maintain sharp cutting tools. This not only enhances the precision of the output but also prolongs the lifespan of the machinery, ensuring a consistent quality of production.

Moreover, the adaptability of CNC milling machines supports a wide range of materials, from metals to plastics, making them indispensable in today’s manufacturing processes. This versatility, paired with precise engineering capabilities, empowers businesses to innovate and respond swiftly to market demands.

Tip: Always consider conducting regular training sessions for operators. Skilled personnel who understand the intricacies of CNC technology can greatly improve both the effectiveness and precision of the manufacturing process.

Industry Applications: Leveraging CNC Milling for Aerospace, Automotive, and Medical Manufacturing

CNC milling machines have emerged as a game-changer in various industries, particularly in aerospace, automotive, and medical manufacturing. According to a report by ResearchAndMarkets, the global CNC machining market is projected to reach USD 100.64 billion by 2025, demonstrating an increasing reliance on this technology. In the aerospace sector, CNC milling is instrumental in producing complex components such as turbine blades and airframes with high precision, enabling manufacturers to meet stringent safety and performance standards.

In the automotive industry, CNC milling facilitates the quick production of prototypes and custom parts, significantly reducing the time-to-market for new vehicles. A study from Deloitte indicates that CNC technology can lower production costs by up to 30%, which is crucial for maintaining a competitive edge in a market where innovation is key. Furthermore, in the medical field, CNC milling provides the ability to create intricate designs for implants and surgical instruments, ensuring each piece matches exact specifications for enhanced patient outcomes.

Tips: When leveraging CNC milling technology, prioritize training your workforce to maximize machine capabilities. Regular maintenance of CNC equipment is vital to maintain precision and efficiency. Lastly, explore software solutions that can optimize machining processes, as this can significantly improve productivity and reduce waste.

Future Trends: The Role of AI and IoT in Enhancing CNC Milling Processes and Capabilities

Artificial Intelligence (AI) is rapidly reshaping the manufacturing landscape by enhancing efficiency and precision in production processes. With the integration of AI, manufacturers are now able to analyze vast amounts of data to optimize workflows, predict maintenance needs, and streamline operations. This not only reduces downtime but also increases the overall adaptability of production systems, enabling companies to respond swiftly to market changes and consumer demands. Advanced algorithms facilitate real-time monitoring and adjustments, ensuring that machining processes are consistently aligned with the highest quality standards.

The convergence of the Internet of Things (IoT) and AI is further amplifying these innovations. Through connected devices, manufacturers can gather insights from machinery and equipment, leading to more informed decision-making. IoT-enabled sensors provide critical information on machinery performance, enabling predictive analytics and reducing the likelihood of unexpected breakdowns. This synergy between AI and IoT is paving the way for smart factories, where automated systems operate with greater autonomy and efficiency. By embracing these technologies, the machine tool industry is transforming, setting new standards for productivity and precision in modern manufacturing.

Related Posts

-

10 Essential Tips for Maximizing Efficiency with Your CNC Lathe and Milling Machine

-

Discovering Precision CNC Milling Machine Alternatives for Enhanced Manufacturing Solutions

-

Top Strategies for Choosing the Best CNC Milling Machine for Your Business Needs

-

Discover How Top Chinese Factories Redefine Excellence in Precision CNC Milling Machines

-

2025 Precision CNC Milling Machine Innovations: Your Ultimate Checklist for Success

-

China's Best Precision CNC Milling Machines Deliver Global Quality You Can Trust