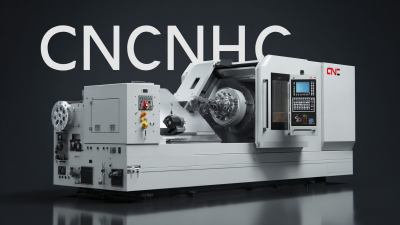

Ultimate Guide to Choosing the Best Metal CNC Machine for Your Business

In the rapidly evolving realm of manufacturing, choosing the right equipment is pivotal to a business's success, especially when it comes to investing in a metal CNC machine. According to a report by MarketsandMarkets, the global CNC machine market is expected to reach $100 billion by 2027, growing at a CAGR of 6.5% from 2022. This surge is driven by increasing automation demands and the need for precision in metalworking processes.

With numerous options available in the market, understanding the key features and benefits of various metal CNC machines is essential for business owners to stay competitive. This guide explores top strategies for selecting the best metal CNC machine tailored to your specific needs, enabling efficient production, cost savings, and enhanced quality control.

Key Factors to Consider When Selecting a Metal CNC Machine for Your Business

When selecting a metal CNC machine for your business, several key factors should be carefully considered to ensure that the investment aligns with your operational needs. First and foremost is the precision and capability of the machine. The rising demand for precision manufacturing, driven by industries like aerospace and defense, underscores the importance of high-quality CNC machines. For instance, recent market reports indicate significant growth in sectors requiring precision machining, which emphasizes the urgency for businesses to adopt advanced CNC technologies that can meet stringent manufacturing standards.

Another critical factor is the integration of modern technologies such as AI and advanced software systems. These innovations not only enhance operational efficiency but also streamline processes such as depowdering in additive manufacturing, as showcased by a recent technological acquisition in the aerospace sector. The ability to leverage AI for predictive maintenance and productivity optimization can significantly impact a company's output and profitability. Therefore, businesses should look for machines that offer advanced features capable of adapting to future demands, ensuring they remain competitive in a rapidly evolving market environment.

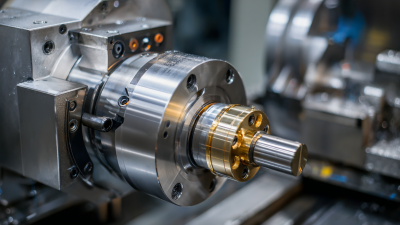

Five Reasons Why Precision Matters in CNC Machining for Metalwork

Precision is the cornerstone of successful CNC machining, especially in metalwork. The first reason precision matters is that it directly impacts the quality of the finished product. In industries such as aerospace and automotive, even the slightest deviation from specifications can result in catastrophic failures. High precision ensures tight tolerances, which ultimately leads to superior performance, reliability, and durability of the components produced.

Moreover, precision enhances efficiency in the production process. Accurate CNC machines allow for minimized material waste, as they make cuts that are closely aligned with the design specifications. This not only reduces costs but also speeds up production times. Lastly, the reputation of a business in the competitive landscape of metalwork heavily relies on its ability to deliver precise and high-quality products consistently. Customers are more likely to return and recommend services when they know they can trust the accuracy of what they receive, making precision a vital aspect of any metal CNC machining operation.

Ultimate Guide to Choosing the Best Metal CNC Machine for Your Business - Five Reasons Why Precision Matters in CNC Machining for Metalwork

| Feature | Importance | Impact on Precision | Recommended Specifications |

|---|---|---|---|

| Spindle Speed | High RPM enhances material cut quality | Directly affects surface finish and detail | 8000 - 24000 RPM |

| Machine Accuracy | Crucial for tight tolerances | Ensures parts fit together as intended | ±0.01 mm |

| Material Compatibility | Extends application range | Affects precision based on material behavior | Aluminum, Steel, Brass, Titanium |

| Control System | Precision in operations and programming | Higher accuracy in complex paths | CNC with advanced CAM software |

| Cooling System | Prevents overheating during operation | Maintains tool integrity and precision | Mist or flood cooling systems |

Understanding Different Types of Metal CNC Machines: Which One is Right for You?

When embarking on the journey of selecting the best metal CNC machine for your business, understanding the various types available is crucial. Different machines cater to specific materials and tasks, making it essential to assess your unique needs before making a choice. For instance, if you frequently work with aluminum or steel, consider machines that are specifically designed to handle these materials, as they often come with the necessary power and precision to deliver superior results.

**Tip 1:** Evaluate your primary materials. CNC machines vary widely in their capability to work with diverse materials like titanium, aluminum, and high-strength steel. Understanding which materials you will predominantly machine is the first step in identifying the right CNC machine for your operation.

**Tip 2:** Consider the complexity of your projects. If your business often engages in intricate designs, investing in a more advanced CNC machine with higher precision and advanced features will pay off in the long run. This not only improves the quality of your outputs but can also enhance productivity through automation.

Ultimately, matching the right CNC machine with your business's material requirements and project complexities will enable you to optimize your manufacturing capabilities and meet market demands efficiently.

Cost vs. Value: Why Investing in Quality Metal CNC Machines Pays Off

When considering a metal CNC machine for your business, it’s crucial to weigh the cost against the value it brings. A cheaper machine may save you money upfront, but it could lead to increased expenses over time due to repairs, maintenance, and lower productivity. Investing in a high-quality metal CNC machine often translates to better precision, reliability, and efficiency, ultimately leading to higher profits.

Tip: Conduct thorough research on the brand’s reputation and user reviews before making a purchase. This will help you gauge the machine's reliability and durability, ensuring your investment pays dividends in the long run.

Additionally, focusing on features that enhance productivity, such as faster operation speeds and advanced software, can provide a competitive edge. While these machines may come with a higher initial investment, the long-term savings and increased output can quickly offset that expense.

Tip: Consider the total cost of ownership rather than just the purchase price. Factor in maintenance costs, expected lifespan, and the potential for upgrades when evaluating your options. A well-chosen machine will not only meet your current needs but also adapt to future demands, solidifying your business's growth.

Maintenance Tips to Ensure Longevity and Performance of Your CNC Machine

When investing in a metal CNC machine, understanding maintenance is key to ensuring longevity and optimal performance. According to a report by the Association for Manufacturing Technology (AMT), regular maintenance can extend the life of CNC machines by up to 50%. This highlights the importance of establishing a routine maintenance schedule that includes daily checks, lubrication, and software updates. By proactively addressing wear and tear, businesses can minimize downtime and enhance productivity.

Additionally, the National Institute of Standards and Technology (NIST) states that unplanned downtime can cost manufacturers anywhere from $5,000 to $250,000 per hour depending on the production scale. Implementing a preventive maintenance program not only safeguards against unexpected failures but also ensures that the CNC machine operates at peak efficiency. Key maintenance practices include monitoring the cooling system, ensuring the accuracy of the tool calibration, and regularly cleaning the machine to prevent debris buildup. By prioritizing these maintenance tips, businesses can both boost machine performance and secure a higher return on investment in their CNC technology.

Related Posts

-

Unveiling the Specifications: The Ultimate Guide to the Best CNC Lathe Machine for Global Buyers

-

China's Best Precision CNC Milling Machines Deliver Global Quality You Can Trust

-

Unlocking Innovation with the Best CNC Machine Milling Machine Options for Global Buyers

-

Discover the Unique Features of Best CNC Lathe Machines and How to Choose the Right One

-

Unleashing Global Excellence in CNC Milling Machines with Premium Quality from China

-

Unlocking Success: Strategies for Sourcing the Best CNC Turning Machine Suppliers