Why Choose CNC Milling Machines for Precision Manufacturing?

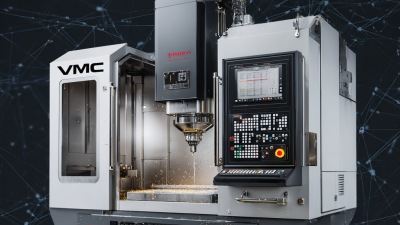

In the realm of precision manufacturing, CNC milling machines have emerged as essential tools that redefine production capabilities and efficiency. Dr. John Smith, an expert in the field of automated manufacturing, emphasizes the significant impact of these technologies: “CNC machine milling machines not only enhance accuracy but also streamline the entire manufacturing process, allowing for remarkable productivity.” This statement encapsulates the transformative role that CNC milling plays in modern production environments, catering to industries that demand high precision and customization.

As manufacturers strive to meet rigorous quality standards and customer specifications, the adoption of CNC machine milling machines has become increasingly prevalent. These advanced machines offer unparalleled versatility, enabling the creation of intricate designs and components with ease. The ability to program and automate complex milling tasks not only minimizes human error but also accelerates production timelines, making CNC milling an undeniable asset in precision manufacturing.

In conclusion, the decision to embrace CNC machine milling technology is marked by substantial benefits, including enhanced accuracy, efficiency, and versatility. As industries continue to evolve, the importance of CNC milling machines in achieving precision manufacturing objectives cannot be overstated, making them pivotal in driving innovation across various sectors.

Advantages of CNC Milling Machines in Precision Manufacturing

CNC milling machines have revolutionized the landscape of precision manufacturing, offering unparalleled accuracy and efficiency. According to a report by MarketsandMarkets, the global CNC milling machine market is projected to grow from $67.3 billion in 2020 to $100.7 billion by 2025, with a compound annual growth rate (CAGR) of 8.5%. This growth underscores the increasing reliance on CNC technology across various industries, including aerospace, automotive, and medical sectors.

One key advantage of CNC milling machines is their ability to produce complex geometries with high precision. The integration of advanced computer software allows for intricate designs to be accurately replicated without the variability often seen in manual machining processes. A study by Research and Markets highlights that CNC machines can achieve tolerances as tight as ±0.01 mm, making them ideal for components requiring stringent specifications. Furthermore, the automation inherent in CNC milling significantly reduces the likelihood of human error, leading to improved product quality and consistency.

Another significant benefit is the efficiency and speed of production. CNC milling machines can operate continuously, reducing cycle times and increasing throughput. According to a report from Technavio, organizations that have switched to CNC machining have reported a reduction in production lead times by up to 30%. This increase in efficiency allows manufacturers to respond more swiftly to market demands and optimize their production processes, ultimately leading to cost savings and enhanced competitiveness in the manufacturing sector.

Advantages of CNC Milling Machines in Precision Manufacturing

Key Specifications and Features of CNC Milling Machines

CNC milling machines are pivotal in precision manufacturing due to several key specifications and features that enhance their performance and reliability. One of the defining characteristics of CNC milling machines is their capability to operate with high-speed machining, achieving spindle speeds that can exceed 20,000 RPM. This high-speed operation not only improves efficiency but also enables the machining of complex geometries with tight tolerances, which are crucial for industries such as aerospace and medical devices. According to a recent report by Market Research Future, the demand for CNC milling machines is projected to grow at a CAGR of 7.5% from 2020 to 2027, underscoring the industry's reliance on precision machining technology.

Another significant feature of CNC milling machines is their advanced control systems, which often utilize high-precision linear guides and ball screws. These components ensure that even the most intricate designs are executed with minimal deviation, often achieving tolerances of ±0.005 mm. The integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) allows for seamless translation of designs into machine instructions, ultimately reducing setup times and increasing overall productivity. A survey conducted by Grand View Research highlighted that about 63% of manufacturers report reduced lead times and improved accuracy by utilizing CNC machinery, indicating the substantial benefits of these advanced manufacturing solutions.

Industry Statistics on CNC Milling's Impact on Production Efficiency

CNC milling machines have become a cornerstone in precision manufacturing, significantly influencing production efficiency across various industries. According to a report by MarketsandMarkets, the global CNC machining market is projected to grow from $63.5 billion in 2020 to $100.4 billion by 2026, indicating an impressive CAGR of 7.6%. This growth is largely attributable to the increased demand for custom parts and components, which can be produced more precisely and quickly using CNC technology compared to traditional machining methods.

In addition to their growing prevalence, CNC milling machines are noted for enhancing productivity. A study by the Manufacturing Institute found that manufacturers who adopted CNC technology reported a productivity increase of up to 30%. This efficiency gain is due to the machines' ability to operate continuously, reducing downtime and allowing for more complex designs that would be challenging with manual processes. As industries strive for greater precision and speed, it is evident that CNC milling plays a critical role in meeting these demands, thereby reshaping the landscape of modern manufacturing.

Comparative Analysis: CNC Milling vs. Traditional Machining Methods

CNC milling has become increasingly popular in precision manufacturing due to its numerous advantages over traditional machining methods. One of the main differences lies in the level of accuracy and consistency that CNC machines can achieve. With computer-controlled processes, CNC milling provides repeatable results that traditional machining often can't match due to human error and variability in manual operations. This precision is particularly crucial in industries that require exact specifications, such as aerospace and medical device manufacturing.

While traditional machining methods may offer a certain degree of flexibility in complex tasks, CNC milling excels in efficiency, especially for large production runs. The automated nature of CNC machines reduces the time spent on setup and allows for continuous operation, leading to increased productivity. Furthermore, CNC milling can handle more complex geometries with ease, enabling manufacturers to produce intricate parts that would be challenging to achieve manually.

Tip: When considering CNC milling for your projects, always assess your specific requirements regarding precision and volume. Investing in CNC technology can significantly enhance the quality and efficiency of your production processes, but ensure that your skilled operators are well-trained to maximize the machine's potential.

Future Trends in CNC Milling Technology and Precision Manufacturing

The landscape of CNC milling technology is rapidly evolving, driven by advancements in automation, artificial intelligence, and materials science. As precision manufacturing demands continue to rise, the future of CNC milling will likely integrate smart technologies that enhance the efficiency and accuracy of machining processes. The incorporation of IoT (Internet of Things) in CNC systems will allow for real-time monitoring and data analysis, enabling manufacturers to predict machine failures and optimize maintenance schedules, thus reducing downtime and increasing productivity.

Moreover, the development of advanced materials and cutting tools will further bolster the capabilities of CNC milling machines. Innovations such as lightweight composites and high-strength alloys require machining solutions that can deliver unparalleled precision. In response, manufacturers are investing in high-speed machining and multi-axis CNC milling technologies, which not only improve production rates but also expand the range of geometries that can be achieved. As these trends continue to unfold, CNC milling will play a crucial role in shaping the future of precision manufacturing, ensuring that it meets the evolving needs of various industries.

Related Posts

-

Ultimate Guide to Choosing the Best VMC Milling Machine for Your Manufacturing Needs

-

Exploring CNC Milling Machine Innovations at the 2025 China Import and Export Fair

-

Exploring the Future of Precision Manufacturing: Best CNC Lathe and Milling Machines for Global Buyers

-

Unlocking Innovation with the Best CNC Machine Milling Machine Options for Global Buyers

-

Chinese Smart Manufacturing Leading the World with the Best Basic CNC Machine Quality Assurance

-

Solutions for Selecting the Best VMC Milling Machine for Your Manufacturing Needs