How to Choose Between CNC Lathe and Milling Machine?

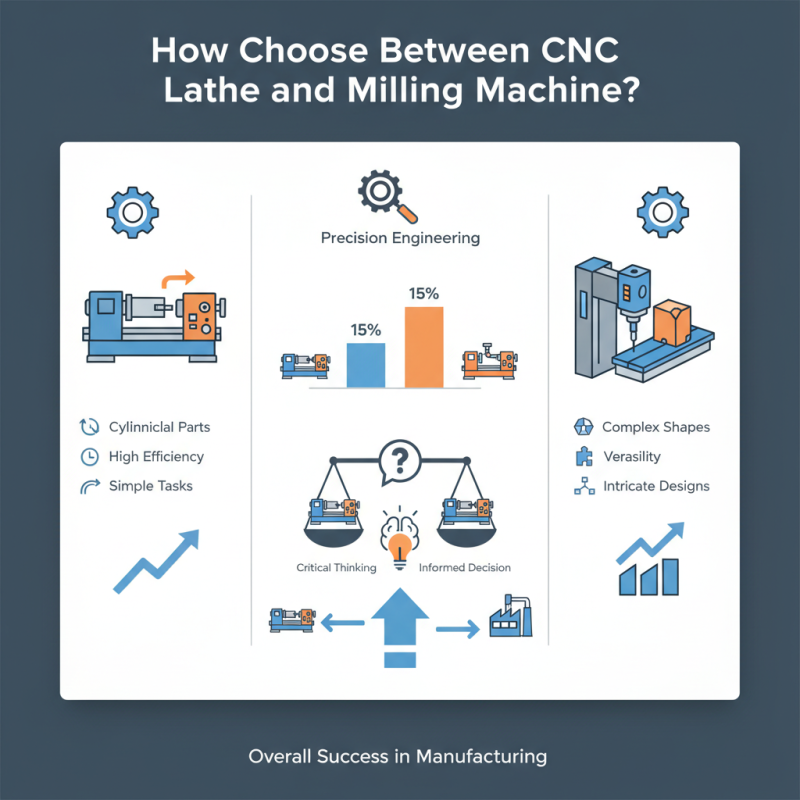

In the modern manufacturing landscape, choosing between a CNC lathe and a milling machine is crucial. Recent industry reports indicate that CNC lathe and milling machine sales have increased by over 15% in the last year. With the rise of precision engineering, understanding the unique capabilities of each machine is more important than ever.

Experts, like John Smith, a leading figure in manufacturing technology, emphasize, "Selecting the right machine can mean the difference between meeting deadlines and facing delays." This insight highlights the operational challenges many businesses face. A CNC lathe excels in producing cylindrical parts with high efficiency, while milling machines offer versatility for complex shapes and surfaces.

However, the choice isn't straightforward. Each option has strengths and weaknesses. For instance, CNC lathes might be more efficient for simple tasks, but milling machines are indispensable for intricate designs. Balancing these factors requires deep understanding and critical thinking. Making an informed decision is essential yet can be daunting. Ultimately, the choice between a CNC lathe and a milling machine shapes production processes and overall success in manufacturing.

Understanding CNC Lathes and Milling Machines: A Brief Overview

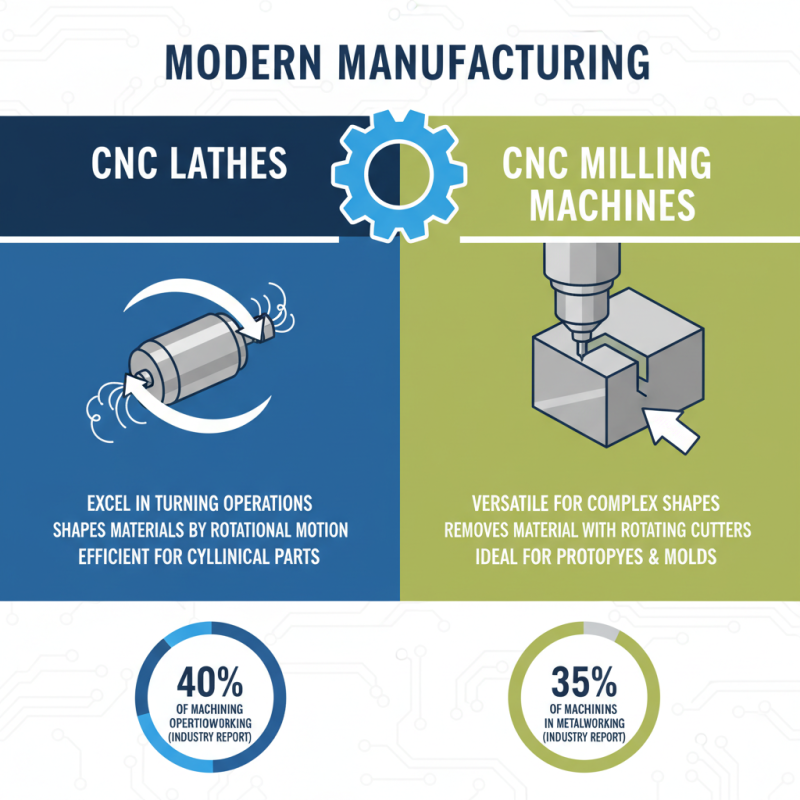

CNC lathes and milling machines play vital roles in modern manufacturing. CNC lathes excel in turning operations. They shape materials by removing excess material in a rotational motion. This method is efficient for creating cylindrical parts. According to a recent industry report, CNC lathes contribute to about 40% of machining operations in metalworking industries.

On the other hand, milling machines use rotary cutters to remove material. They are ideal for creating complex shapes and features on flat surfaces. Reports indicate that the milling machine market is projected to grow by 5% annually. While CNC lathes are great for mass production, milling machines offer flexibility for detailed designs. However, makers must consider their specific projects carefully. Relying solely on one type may limit capabilities.

Choosing between them is often challenging. Users may overlook the advantages of each. For example, complex components might require switching between machines, which can increase lead times. Understanding the strengths and weaknesses helps in making informed decisions. Knowing when to use a lathe or a mill can greatly impact the final product quality. Make sure to weigh in your production needs before deciding.

Key Differences Between CNC Lathes and Milling Machines

When choosing between a CNC lathe and a Milling Machine, understanding their key differences is crucial. CNC lathes are effective for producing cylindrical parts. They excel in high-speed rotation, allowing for efficient material removal. In contrast, Milling machines are versatile, capable of handling more complex shapes and larger workpieces.

Industry reports reveal that about 40% of manufacturers prefer CNC milling for intricate designs. These machines can perform multiple operations, like drilling and contouring, in one setup. However, CNC lathes dominate in high-volume production with simpler geometries, offering faster cycle times for those applications. A case study shows that switching from a milling process to a CNC lathe increased production speed by 30% for certain cylindrical components.

Choosing the right machine often involves compromises. While CNC lathes maximize speed, they may lack the flexibility of milling machines. Conversely, milling machines can be slower and require more setup time. This trade-off makes it essential to clearly define production needs before making a decision. It's not just about speed or complexity but aligning machine capabilities with specific manufacturing goals.

Factors to Consider When Choosing a CNC Lathe or Milling Machine

When choosing between a CNC lathe and a milling machine, consider your project needs. CNC lathes excel in creating cylindrical parts. They are ideal for turning operations. A milling machine, on the other hand, offers more versatility for flat or complex shapes. Your choice depends on the workpieces you intend to create.

Evaluate the material you will use. Different machines handle materials differently. Harder materials may require a CNC lathe, while softer ones are suited for milling machines. Think about the precision required for your projects. High tolerance demands might favor milling machines.

**Tips:** Start small. Test both machines with simple projects before committing. This allows you to understand their unique capabilities. Also consider space and budget constraints, as both machines can be significant investments. Ensure you have the right tooling and software to optimize their use.

Comparison of CNC Lathe and Milling Machine Features

Applications and Industries for CNC Lathes and Milling Machines

CNC lathes and milling machines serve different roles in manufacturing. CNC lathes excel in producing cylindrical parts. They are essential in the automotive and aerospace sectors. A recent industry report shows that the CNC lathe market is projected to grow at a CAGR of 7.1% through 2026. This reflects an increasing demand for precision components.

On the other hand, milling machines are versatile. They can create detailed shapes and features on flat materials. Industries such as electronics and medical device manufacturing often rely on milling for complex part production. According to a 2023 study, the global market for CNC milling machines is expected to reach USD 5.5 billion by 2025. This signals robust growth, indicating a need for skilled operators.

Choosing between these machines can be challenging. Each machine has its advantages and limitations. For example, CNC lathes may struggle with intricate designs, while milling machines might lack efficiency on round objects. Understanding the specific applications in your industry is crucial. Evaluate your production needs carefully. Remember, sometimes the best choice isn’t clear-cut.

Cost and Maintenance Considerations for CNC Equipment

When selecting between a CNC lathe and a milling machine, cost and maintenance are crucial. CNC lathes typically have lower initial costs. They are simpler machines, making them easier to budget for. However, maintenance costs can rise. Parts may wear out faster, especially with heavy usage.

Milling machines often come with a higher price tag. They can handle more complex tasks, offering great versatility. Yet, their maintenance can also be demanding. Regular checks are needed for multiple components. Neglecting this can lead to major issues.

Consider your production needs. If your projects are straightforward, a CNC lathe could suffice. For varied tasks, investing in a milling machine might be wise. However, always factor in the long-term expenses. These costs can impact your bottom line significantly. Analyze your workflow, and choose what aligns best with your operational demands.

Related Posts

-

Innovative Solutions for Enhancing Precision with CNC Lathe and Milling Machine Technology

-

Top 7 CNC Lathe and Milling Machines for Precision Engineering in 2023

-

Navigating the Future: 2025 Market Insights and How to Choose the Best Basic CNC Machine

-

10 Essential Tips for Maximizing Efficiency with Your CNC Lathe and Milling Machine

-

Revolutionizing Precision with CNC Metal Milling Machines for Modern Manufacturing

-

Innovative Trends for Best CNC Machine Milling Machine in 2025 Shaping the Future of Manufacturing