2025 How to Choose the Right CNC Milling Machine for Your Projects

Selecting the right CNC milling machine is a pivotal decision for any project that demands precision and efficiency. As industries continue to evolve, the need for advanced machining tools has become increasingly vital. A CNC machine milling machine offers the automation and accuracy necessary to enhance productivity and deliver high-quality results. However, the multitude of options available can be overwhelming for both seasoned professionals and newcomers alike.

When choosing a CNC milling machine, it's essential to consider a variety of factors that can influence your decision. These include the machine's capabilities, the types of materials it can handle, and the specific requirements of your projects. Understanding the key features and technical specifications of various machines will empower you to make an informed choice that aligns with your operational needs. Ultimately, investing in the right CNC machine milling machine can significantly impact your workflow, ensuring that you achieve optimal results while minimizing downtime and costs.

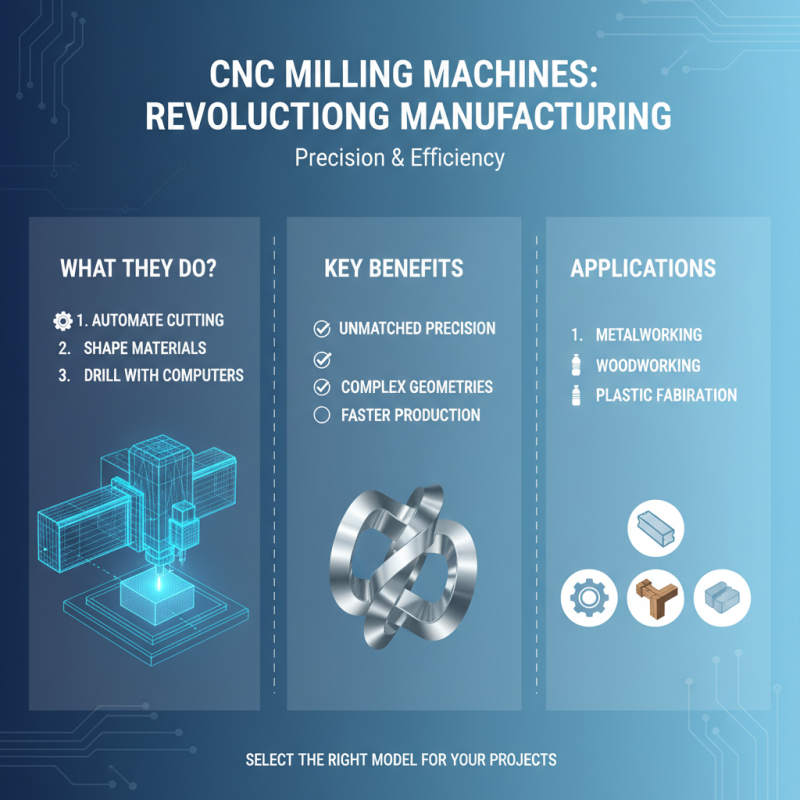

Understanding CNC Milling Machines and Their Applications

CNC milling machines have revolutionized the manufacturing landscape, offering precision and efficiency that traditional machining methods struggle to match. These machines use computer numerical control to automate the cutting, shaping, and drilling of materials, allowing for intricate designs and complex geometries to be created with ease. Understanding the various applications of CNC milling machines is essential for selecting the right model for your projects, whether you are in metalworking, woodworking, or plastic fabrication.

The applications of CNC milling machines are vast and varied, ranging from producing small prototypes to large-scale industrial components. In aerospace, these machines create lightweight yet sturdy parts, while in the automotive industry, they are essential for crafting engine components with tight tolerances. In woodworking, CNC mills can produce intricate carvings and furniture parts, showcasing the versatility these machines bring to different sectors. By analyzing the specific requirements of your project—such as the type of material, required precision, and production volume—you can determine the most suitable CNC milling machine to enhance your production capabilities.

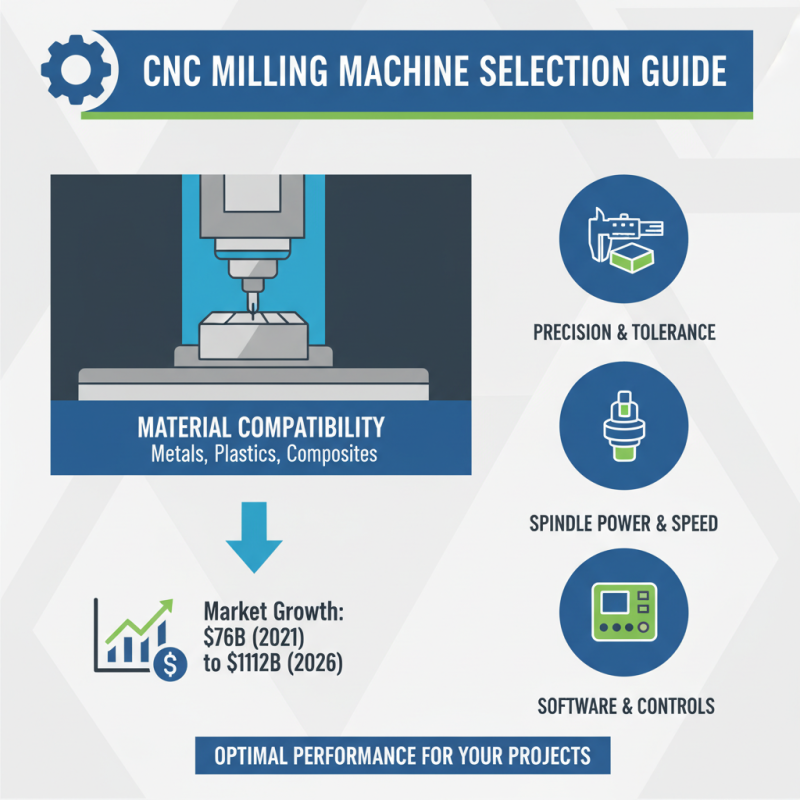

Key Factors to Consider When Selecting a CNC Milling Machine

When selecting a CNC milling machine for your projects, several key factors must be considered to ensure optimal performance and suitability. One of the primary considerations is the material compatibility; different CNC milling machines are designed to handle various materials, including metals, plastics, and composites. According to a report by MarketsandMarkets, the CNC machine market is expected to grow from $76 billion in 2021 to $112 billion by 2026, indicating increasingly sophisticated machines that can work with diverse materials.

Another critical factor is the machine’s precision and tooling capabilities. The right CNC milling machine should provide the required accuracy while also offering versatility in tooling options. Precision is often measured in microns, with high-quality machines capable of achieving tolerances of ±0.001 inches. Furthermore, the size and complexity of the projects you intend to undertake should dictate your choice of machine; larger projects might necessitate a machine with a greater capacity and enhanced rigidity to maintain accuracy over extended periods.

Lastly, consider the machine’s software and ease of use. Advanced CNC milling machines often come equipped with user-friendly interfaces and software that streamline the design-to-production process. The integration of CAD/CAM software is a significant trend, as it improves efficiency and reduces errors in production. The 2023 Global CNC Machines Market Research, published by Fortune Business Insights, indicates that end-users favor machines with flexible operation and enhanced programmability, which can dramatically improve workflow efficiency in both small and large-scale applications.

Types of CNC Milling Machines and Their Features

When choosing a CNC milling machine, understanding the various types available and their features is crucial to ensuring they meet your project requirements. The most common types include vertical and horizontal milling machines. Vertical CNC mills hold the workpiece vertically, allowing for intricate designs and precision cuts, making them ideal for complex components. These machines typically excel in applications such as mold making and prototype production due to their versatility and ease of use.

On the other hand, horizontal CNC milling machines have a horizontal spindle orientation, which is advantageous for heavy-duty machining tasks and larger workpieces. They provide stability and can handle multiple sides of a part simultaneously, increasing efficiency and reducing production time. Additionally, machining centers that combine milling and drilling capabilities offer a range of functionalities in a single setup, further enhancing productivity. Each type of machine serves specific purposes, so assessing your project needs will help you select the right CNC milling machine that aligns with your objectives.

Types of CNC Milling Machines and Their Features

This chart displays the various types of CNC milling machines commonly used in the industry and their features. Each type is represented by the number of applications or projects they're typically employed in.

Evaluating the Technical Specifications for Your Needs

When selecting the right CNC milling machine for your projects, understanding the technical specifications is paramount. Consider factors such as the machine's spindle speed, feed rate, and cutting capacity. Spindle speed indicates how fast the machine can rotate the cutting tool, which is crucial for different materials. A higher spindle speed is often necessary for softer materials like aluminum, whereas tougher materials like steel require a balance between speed and torque.

Tips: Take note of the maximum cutting depth and width. This will ensure that the machine can handle the dimensions of your workpieces efficiently. Additionally, look into the machine’s accuracy and repeatability specifications, as these will affect the quality of your finished products.

Another essential specification is the machine's axis configuration. Most CNC milling machines come in 3-axis configurations, but for more complex shapes, 4-axis or even 5-axis machines might be necessary. The additional axes allow for more versatile machining operations, enabling you to work on intricate designs without having to reposition the workpiece.

Tips: Don't overlook the software compatibility that comes with the machine, as this can significantly impact your workflow. Make sure the CNC milling machine can integrate with the design software you plan to use, ensuring a seamless transition from design to manufacturing.

Cost Considerations and Budgeting for CNC Milling Machines

When selecting a CNC milling machine, cost considerations play a pivotal role in ensuring that projects remain feasible and profitable. Prices for CNC milling machines can vary significantly, depending on factors such as machine size, capabilities, and technology. According to a recent industry report, the average cost of entry-level CNC milling machines can range from $5,000 to $10,000, while high-end models designed for precision and heavy-duty work can exceed $100,000. Thus, it is crucial for businesses to establish a clear budget that aligns with their operational needs and project demands.

In addition to the initial purchase price, operational costs must also be factored into budget planning. Maintenance, tooling, and software expenses can add up quickly over the lifespan of the machine. A 2022 report indicated that companies should expect to spend approximately 5-10% of the initial machine cost annually on maintenance and tooling supplies. Furthermore, the choice between purchasing new versus used machines can greatly affect overall expenses; lightly used machines can provide substantial savings while still delivering the necessary precision and capabilities. Properly assessing both upfront and ongoing costs is essential for making informed decisions that enhance project outcomes and ensure a positive return on investment.

2025 How to Choose the Right CNC Milling Machine for Your Projects - Cost Considerations and Budgeting for CNC Milling Machines

| Model | X-Axis Travel (mm) | Y-Axis Travel (mm) | Z-Axis Travel (mm) | Max Spindle Speed (RPM) | Price (USD) |

|---|---|---|---|---|---|

| CNC Machine A | 600 | 400 | 300 | 8000 | $20,000 |

| CNC Machine B | 500 | 450 | 250 | 10000 | $15,000 |

| CNC Machine C | 700 | 500 | 350 | 12000 | $25,000 |

| CNC Machine D | 400 | 300 | 200 | 5000 | $10,000 |

| CNC Machine E | 850 | 600 | 400 | 15000 | $30,000 |

Related Posts

-

Top Strategies for Choosing the Best CNC Milling Machine for Your Business Needs

-

Exploring the Future of Precision Manufacturing: Best CNC Lathe and Milling Machines for Global Buyers

-

Top Benefits of Using Precision CNC Milling Machines in Modern Manufacturing

-

Top 7 CNC Lathe and Milling Machines for Precision Engineering in 2023

-

Revolutionizing Precision with CNC Metal Milling Machines for Modern Manufacturing

-

How to Choose the Right Metal CNC Machine for Your Business Needs