How to Choose the Best CNC VMC Machine for Your Needs?

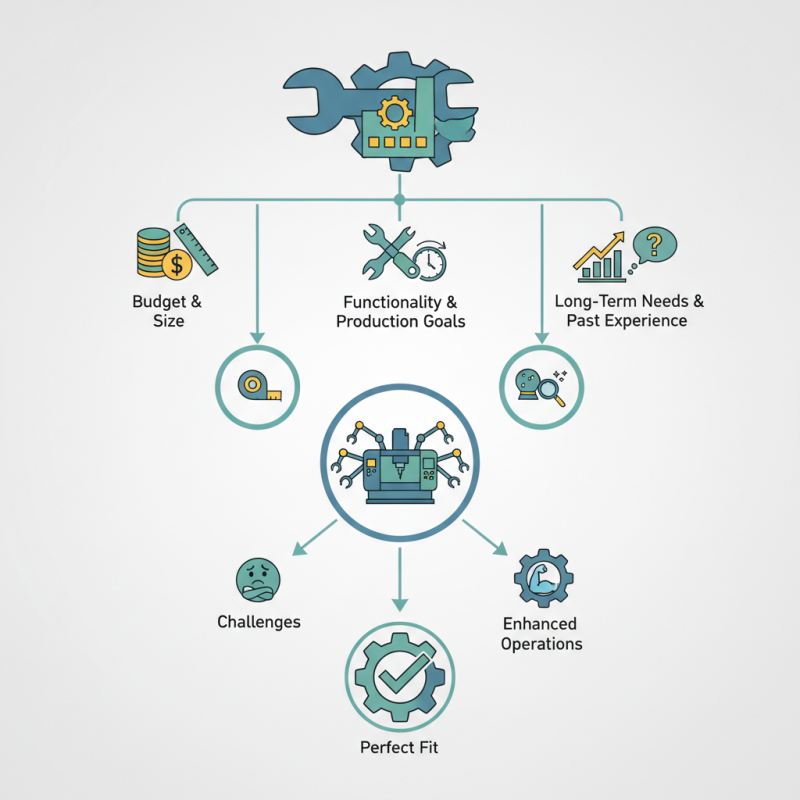

Choosing the right CNC VMC machine is crucial for your business. Your decision impacts production efficiency and final product quality. Selecting a machine involves understanding your specific needs and application requirements.

You must consider various factors, such as budget, size, and functionality. A suitable CNC VMC machine should align with your production goals. However, finding the perfect fit can feel overwhelming. Every option may not meet all your expectations.

Think about the features you need, like tool changers and spindle speeds. It's vital to assess your long-term goals. Reflection on past experiences can guide you. Sometimes, ideal specifications may lead to unexpected challenges. Ultimately, the right CNC VMC machine can enhance your operations significantly.

Understanding the Basics of CNC VMC Machines

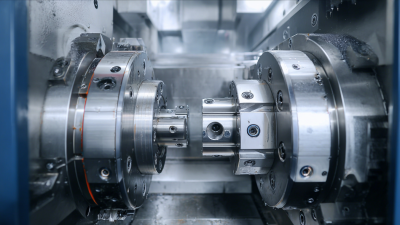

CNC VMC machines are crucial for modern machining. Understanding their basic components and functions is vital. A CNC VMC (Vertical Machining Center) combines precision and versatility. It can handle complex tasks with ease. However, choosing one can be daunting.

The core components include the spindle, worktable, and tool changer. The spindle is responsible for the rotation of cutting tools. A robust spindle ensures better performance. The worktable supports the material during machining. It's important to choose one that fits your project size. Tool changers increase efficiency. They can switch tools automatically, saving time.

However, not all machines are created equal. Some may have features you don't need. Others might be low quality but still tempt you with a lower price. Assessing your actual needs is crucial. Reflect on your typical projects. This assessment helps you avoid overspending. Balancing quality and price is often a tricky endeavor. Taking time for this reflection can lead to better decisions.

Key Factors to Consider When Selecting a CNC VMC Machine

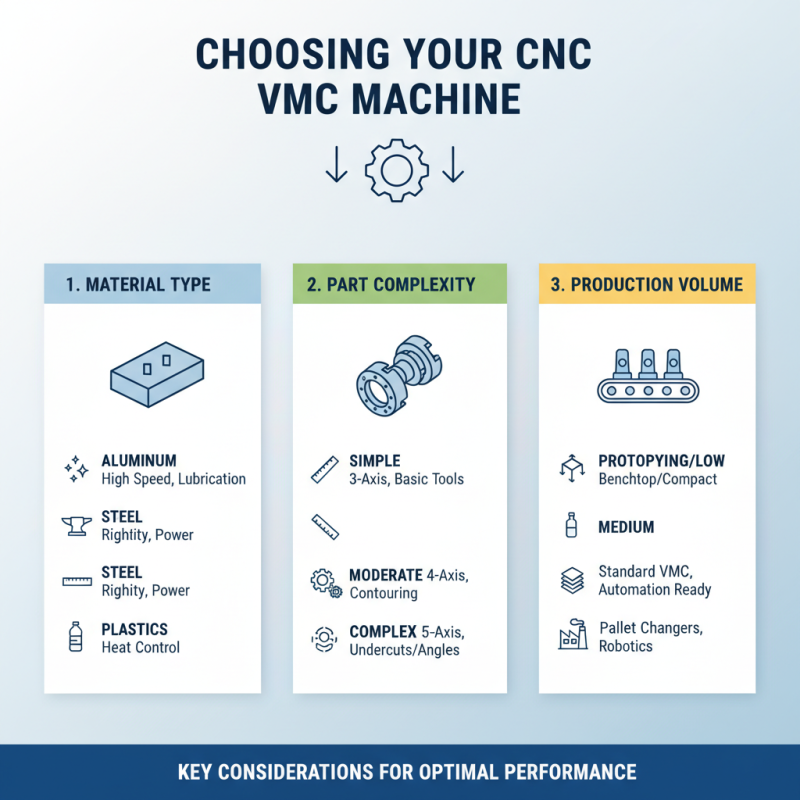

Choosing the right CNC VMC machine can be challenging. Start by considering your specific needs. What materials will you be working with? Aluminum, steel, or plastic? Each material has different machining requirements. Ensuring your machine can handle the materials is essential.

Next, think about the size of your workpieces. If you commonly work with larger items, a machine with a bigger table is a must. On the contrary, for small parts, a compact machine might suffice. It’s also important to consider the spindle speed and power. Higher RPMs can reduce machining time, but it may not be necessary for all operations.

Don't overlook the control software. Intuitive interfaces can simplify operation. Complex software can be a hurdle if your team isn't trained. While advanced features are attractive, sometimes simpler is better. It's crucial to balance necessary functions with ease of use. Lastly, evaluate operational costs including maintenance. High-quality machines might seem expensive upfront, but they can save money in the long run. Think about all these aspects carefully before making a choice.

Evaluating Your Specific Machining Needs and Applications

When selecting a CNC VMC machine, understanding your specific machining needs is critical. Consider the type of materials you'll be working with. For instance, steel, aluminum, and plastics all have different machining requirements. According to a recent industry report, approximately 45% of machining operations involve metals.

Tips: Clearly define your material types before making a choice.

Next, evaluate the size and complexity of your projects. Larger workpieces may need a machine with a bigger work envelope. Many reports indicate that efficiency can drop significantly with undersized machines. Striking the right balance can prevent delays and increase productivity.

Tips: Test the machine's capabilities on similar projects before purchasing.

Analyze your production volume as well. A machine optimized for high-volume production might not be ideal for low-volume runs. Some companies find that versatility in their CNC machines is limited. This can lead to issues, especially if adapting to new market demands.

Tips: Be cautious about future needs; adaptability matters.

Comparing Different Brands and Models of CNC VMC Machines

When selecting a CNC VMC machine, comparing different brands and models is crucial. Each manufacturer offers unique features, such as control systems and spindle speeds. Some machines excel in precision, while others prioritize speed. It's essential to consider what matters most to your production needs. Look for machines that offer customizable options. This provides flexibility as your requirements may change.

It's important to evaluate the available after-sales support for each brand. Some offer extensive training while others may lack sufficient guidance. Researching user reviews can shed light on real-world performance. Don't overlook the importance of maintenance schedules, which vary widely among machines. Often, low upfront costs can lead to higher long-term expenses due to part replacements and repairs.

Additionally, consider software compatibility. Some VMC machines might not integrate well with existing systems. Testing the machine demo can reveal hidden issues. Be prepared for your assumptions to be challenged. A machine that looks great on paper may not meet your expectations in practice. Keep an open mind throughout the decision-making process.

How to Choose the Best CNC VMC Machine for Your Needs?

| Model | Type | Working Area (mm) | Spindle Speed (RPM) | Tool Capacity | Control System | Price ($) |

|---|---|---|---|---|---|---|

| Model A | Vertical | 800 x 500 x 500 | 12000 | 24 | Fanuc | 25,000 |

| Model B | Horizontal | 1000 x 800 x 600 | 10000 | 30 | Siemens | 35,000 |

| Model C | Vertical | 600 x 400 x 400 | 8000 | 16 | Haas | 20,000 |

| Model D | Vertical | 900 x 600 x 500 | 15000 | 24 | Mitsubishi | 30,000 |

Budget Considerations and Cost-Effectiveness in Your Choice

When selecting a CNC VMC machine, budget considerations are crucial. The initial purchase cost is only part of the equation. Other expenses, like maintenance and tooling, can add up quickly. It’s wise to create a detailed budget plan that includes these factors. Many overlook long-term costs, focusing only on the purchase price. This oversight can lead to financial strain later.

A cost-effective machine will have a balance between price and capability. Consider what features you truly need. Extra functions may seem appealing but can inflate costs unnecessarily. Aim for a machine that meets your specific requirements without going overboard. Pay attention to the machine's efficiency and energy consumption, as these factors greatly influence operational costs over time.

After you assess your budget and needs, reflect on the choices available. Sometimes, spending slightly more on a reliable machine can be better than opting for a cheaper version that could break down. You may regret those savings if it leads to higher repairs. Finding the right balance can be challenging, but it’s essential for long-term success in your machining projects.

Related Posts

-

Chinese Smart Manufacturing Leading the World with the Best Basic CNC Machine Quality Assurance

-

Navigating Global Trade: Understanding Import and Export Certifications for the Best Types of CNC Machines

-

Ultimate Guide to Selecting the Best CNC Lathe Machine for Your Business Needs

-

Ultimate Guide to Choosing the Best Types of CNC Machines for Your Business Needs

-

2024 Ultimate Guide to Best Mill Turn Machines for Global Buyers

-

Top Strategies for Maximizing Efficiency with the Best Home Shop CNC Machine