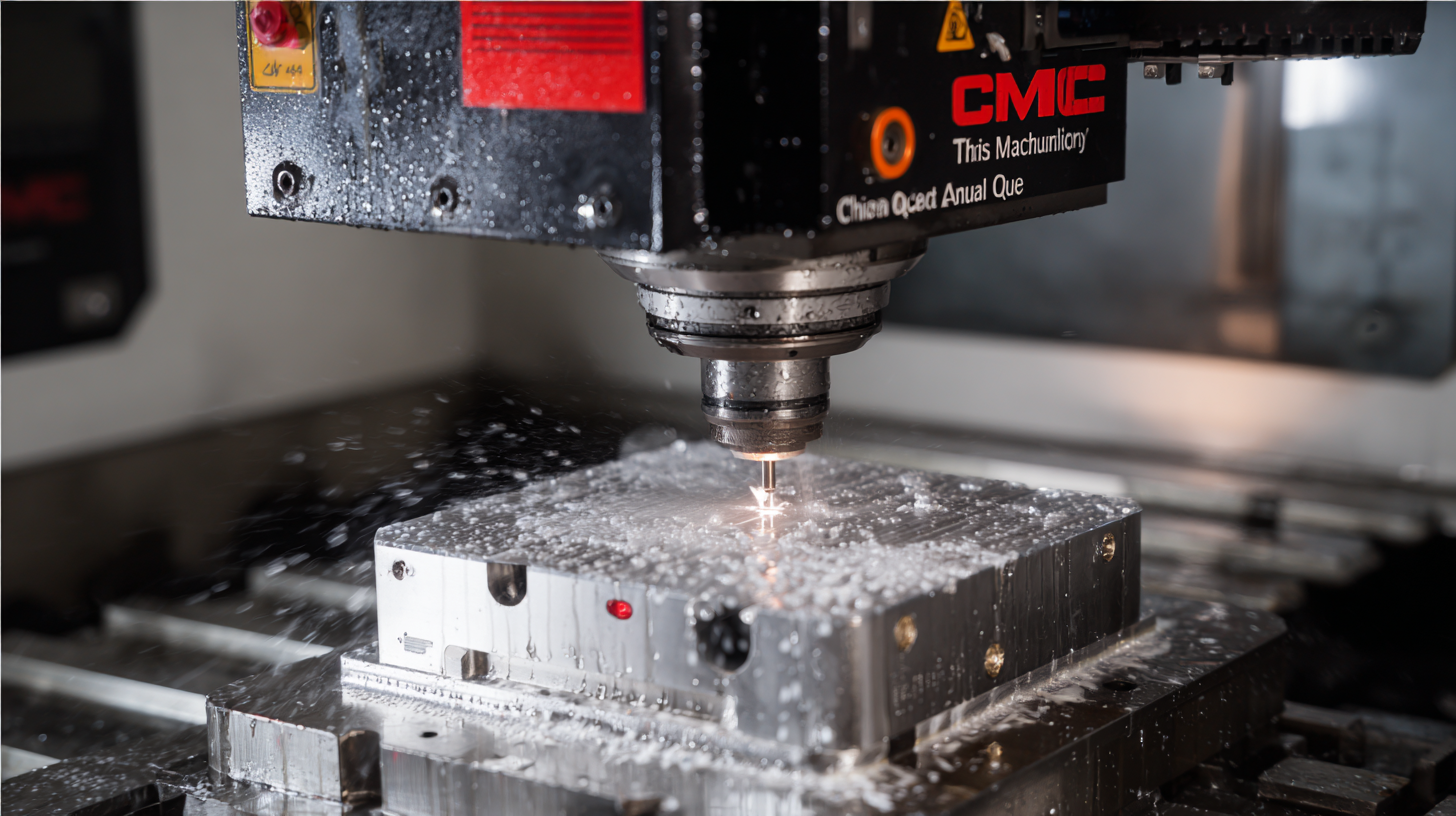

Chinese Smart Manufacturing Leading the World with the Best Basic CNC Machine Quality Assurance

In recent years, China has emerged as a frontrunner in the realm of smart manufacturing, particularly in the production of high-quality basic CNC machines. According to a report by the International Federation of Robotics, the global market for CNC machines is expected to reach

$100 billion by 2025, with a significant portion of this growth driven by innovative manufacturing techniques originating from China.

The country's emphasis on smart technology integration and automation has enabled manufacturers to produce basic CNC machines that not only meet but exceed international quality standards. With exports to over 200 countries, China is not just a manufacturer; it is redefining the landscape of global manufacturing. As companies around the world seek reliable and advanced machining solutions, the quality assurance practices employed in Chinese factories are setting a new benchmark, ensuring that

"Made in China" resonates with excellence and reliability in the basic CNC machine segment.

The country's emphasis on smart technology integration and automation has enabled manufacturers to produce basic CNC machines that not only meet but exceed international quality standards. With exports to over 200 countries, China is not just a manufacturer; it is redefining the landscape of global manufacturing. As companies around the world seek reliable and advanced machining solutions, the quality assurance practices employed in Chinese factories are setting a new benchmark, ensuring that

"Made in China" resonates with excellence and reliability in the basic CNC machine segment.

Importance of Quality Assurance in CNC Machine Manufacturing

Quality assurance plays a pivotal role in the manufacturing of CNC machines, particularly as the industry evolves toward greater complexity and precision. In China, where smart manufacturing is rapidly advancing, the emphasis on quality assurance ensures that CNC machines not only meet but exceed international standards. This commitment to excellence fosters confidence among global buyers, as they know that these machines will deliver superior performance, durability, and reliability.

When focusing on quality assurance in CNC machine manufacturing, companies should prioritize the implementation of rigorous testing protocols during production.

Tip 1: Regularly schedule thorough inspections at various stages of the manufacturing process to catch any defects early, thereby minimizing waste and reallocating resources efficiently.

Tip 2: Invest in employee training programs that emphasize quality control techniques, empowering staff to recognize and resolve potential issues proactively.

Moreover, the integration of advanced technologies such as AI and IoT in smart manufacturing can greatly enhance quality assurance.

Tip 3: Utilize predictive maintenance systems to monitor machine performance in real-time, enabling timely adjustments that maintain product quality. Through these measures, Chinese manufacturers are setting the benchmark for quality assurance, ultimately leading the world in the CNC machine sector.

Key Features of China's Advanced CNC Machines

China has rapidly emerged as a leader in smart manufacturing, particularly through its advanced CNC (Computer Numerical Control) machines, which are characterized by several key features. One of the most significant aspects of these machines is their integration of artificial intelligence. The advent of generative AI has transformed CNC operations, facilitating enhanced automation and precision. According to industry reports, the global CNC market is expected to grow significantly, reaching USD 100 billion by 2028, driven by advancements in AI technologies (Source: Global CNC Market Report).

Moreover, Chinese CNC machines boast superior quality assurance processes, with rigorous testing protocols that ensure peak performance and reliability. Features such as adaptive learning algorithms and real-time monitoring not only optimize production efficiency but also reduce waste. As manufacturers embrace data-centric AI approaches, the capabilities of CNC machines are further enhanced through improved feature engineering, leading to better outcomes in terms of production speed and product quality.

The emphasis on quality and cutting-edge technology has positioned China at the forefront of the CNC manufacturing industry. With a focus on innovation and continuous improvement, Chinese manufacturers are setting new benchmarks that are being closely watched by global competitors. As a result, the influence of China's advanced CNC technology is expected to shape the future of smart manufacturing worldwide.

Chinese Smart Manufacturing Leading the World with the Best Basic CNC Machine Quality Assurance - Key Features of China's Advanced CNC Machines

| Feature | Description | Benefit | Industry Applications |

|---|---|---|---|

| High Precision | CNC machines are capable of producing parts with tight tolerances. | Enhances product quality and reduces waste. | Aerospace, Automotive, Medical Devices |

| Robust Automation | Integration of advanced robotics for enhanced production efficiency. | Increases throughput and reduces labor costs. | Manufacturing, Electronics, Defense |

| Versatile Materials Processing | Ability to work with a wide range of materials including metals and plastics. | Enables diverse product manufacturing. | Consumer Goods, Machinery, Furniture |

| Data-Driven Insights | Utilization of IoT for real-time data analysis and monitoring. | Improves decision-making and operational efficiency. | Industrial Automation, Supply Chain Management |

| Energy Efficiency | Innovative technologies reducing energy consumption. | Lower operating costs and environmental impact. | All manufacturing sectors |

Comparative Analysis: Chinese CNC Machines vs. Global Competitors

In recent years, Chinese CNC machines have gained substantial traction in the global market, often outpacing their international counterparts in both technology and affordability. When conducting a comparative analysis, we can see that Chinese manufacturers focus on innovation, leveraging advanced technologies like IoT and AI to enhance production efficiency. These high-tech adaptations not only boost the precision of CNC machines but also reduce operational costs, making them attractive choices for businesses looking to optimize their manufacturing processes.

Tip: When evaluating CNC machines, look for features such as adaptive control systems and real-time monitoring capabilities. Such technologies can significantly improve the overall productivity of your operations.

Moreover, while some global competitors traditionally offered superior brand value, many Chinese companies have demonstrated a commitment to quality and reliability. With rigorous quality assurance processes in place, Chinese CNC machine manufacturers are steadily building a reputation that rivals that of established brands. The combination of state-of-the-art manufacturing techniques and competitive pricing positions Chinese CNC machines favorably in the global arena.

Tip: Always request samples or conduct trials before committing to a large purchase, as firsthand experience can provide invaluable insights into the machine's performance and suitability for your specific needs.

Real-World Applications of High-Quality CNC Machines in Industries

The global CNC machine market is experiencing significant growth, driven by increasing demand across various industries, particularly in metal cutting and metal forming applications. According to recent industry analyses, the CNC machine market is projected to reach over $100 billion by 2026, with a compound annual growth rate (CAGR) of around 6.5% from 2021 to 2026. This growth is largely fueled by advancements in automation and the rising need for high precision and efficiency in manufacturing processes.

In industries such as aerospace, automotive, and electronics, high-quality CNC machines play a pivotal role in enhancing productivity and ensuring accuracy. For instance, these machines are utilized for complex parts fabrication, optimizing production lines, and facilitating rapid prototyping. The ability to create intricate designs with minimal human intervention not only streamlines operations but also significantly reduces the risk of errors. As companies continue to invest in smart manufacturing technologies, the role of CNC machines, characterized by superior quality assurance, becomes increasingly vital in maintaining competitive advantages in the global market.

Real-World Applications of High-Quality CNC Machines in Industries

Future Trends in Smart Manufacturing and CNC Technology

The rise of the Industrial Internet of Things (IIoT) is fundamentally reshaping the landscape of smart manufacturing. This transformation helps industries to not only enhance efficiency but also to innovate their production processes. By integrating IIoT technologies, manufacturers can achieve greater connectivity between machines, improving data collection and analysis. This leads to smarter decision-making, reduced downtime, and optimized resource management, thereby driving the competitive edge in global markets.

A crucial aspect of IIoT's evolution is the establishment of a five-layer intelligent architecture. This framework enables organizations to systematically progress from basic connectivity to advanced analytics and autonomous decision-making systems. Within this structure, seven essential technologies have been identified that act as accelerators for the transformation of the manufacturing sector. These technologies include advanced sensors, cloud computing, edge computing, artificial intelligence, cybersecurity measures, and more, all of which play significant roles in enhancing productivity and enabling more innovative manufacturing capabilities. The continued development and integration of these technologies will undoubtedly propel smart manufacturing to new heights.