2026 Best VMC Milling Machines for Precision Machining?

The demand for precision in machining has never been greater. The global VMC milling machine market is projected to reach $5.5 billion by 2026. This growth highlights the industry's need for machines that provide accuracy and efficiency. VMC milling machines are at the forefront of this transformation, offering capabilities that are unmatched in both performance and versatility.

Advanced features in modern VMC milling machines, such as multi-axis functionality and CNC controls, allow for intricate designs and tight tolerances. Despite the advances, some challenges persist. Issues such as machine calibration and maintenance significantly impact operational efficiency. Companies must remain vigilant and proactive in addressing these concerns to fully benefit from technology.

Choosing the best VMC milling machine involves careful consideration. Factors like spindle speed, tooling options, and software compatibility play crucial roles. Businesses can no longer afford to overlook these details. In the pursuit of excellence, ensuring reliability and upgrading skills are essential. The right machine can ultimately define a company's competitive edge in today’s demanding manufacturing landscape.

Overview of VMC Milling Machines and Their Importance in Precision Machining

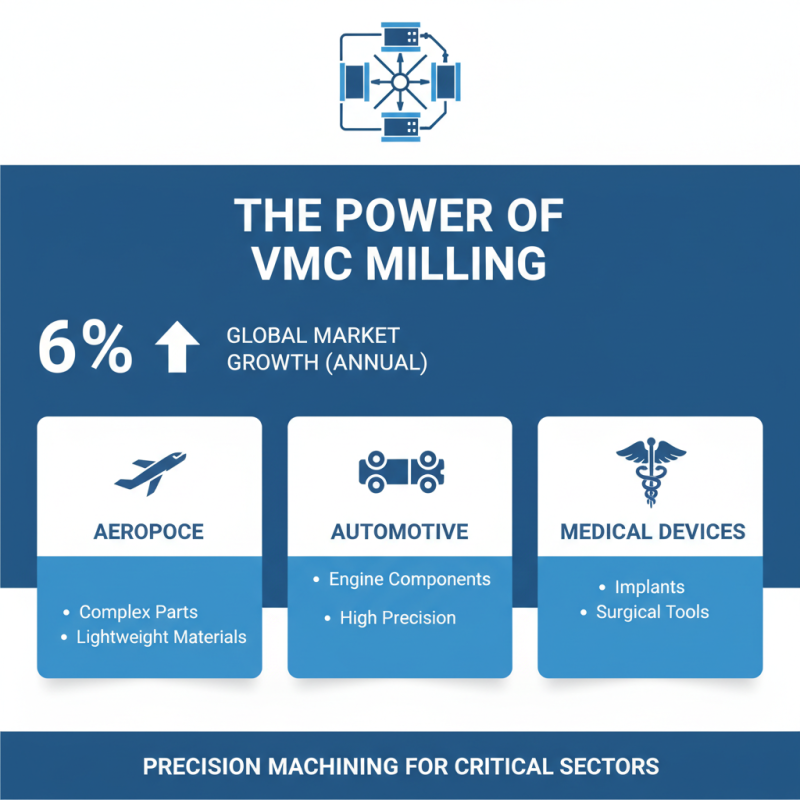

VMC (Vertical Machining Center) milling machines play a crucial role in precision machining. They enable manufacturers to produce complex parts with high accuracy. According to a recent industry report, the global VMC market is expected to grow by 6% annually over the next few years. This growth highlights their significance in various sectors, including aerospace, automotive, and medical device manufacturing.

Precision is essential in machining. A small error can lead to significant product failure. VMCs typically feature advanced controls that enhance accuracy. However, not all machines deliver the same precision. In fact, less than 80% of manufacturers report fully satisfied with their machining tolerances. This often leads to costly reworks and delays.

Furthermore, the integration of automation in VMC milling has its ups and downs. While it boosts efficiency, it requires skilled operators for setup and maintenance. The lack of experienced personnel may hinder overall performance. Investing in training programs can be beneficial, but many companies overlook this. Hence, without proper training, even the best machines may underperform.

Key Features to Consider When Choosing a VMC Milling Machine

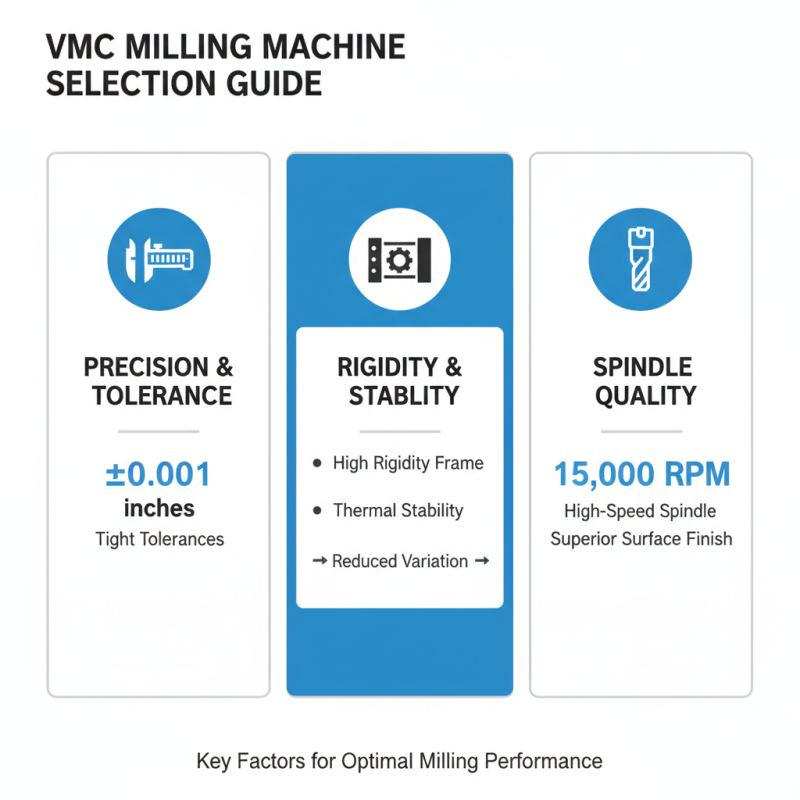

When selecting a VMC milling machine, precision is key. Machines should offer tight tolerances, ideally within ±0.001 inches. Reports indicate that machines with high rigidity and thermal stability reduce variation during milling. Rigid frames help maintain accuracy. The importance of spindle quality cannot be overstated, as spindles directly affect surface finish and machining speeds. A high-quality spindle can maintain speeds up to 15,000 RPM.

Another crucial feature is the CNC control system. Modern systems provide enhanced automation and user interfaces. A study showed that efficient CNC systems increase productivity by 20%. User-friendly controls and touch screens simplify operations for new operators. However, many older systems are still in use, presenting a learning curve for teams.

Tool capacity and versatility also matter. Machines with larger tool changers minimize downtime. Data reveals that shops using versatile machines often achieve a 30% improvement in job turnaround time. Consideration of maintenance and support options is essential, too. Machines sometimes require frequent calibration, which can lead to significant unplanned downtime. Therefore, understanding potential maintenance costs is paramount when making a purchase.

Top 2026 VMC Milling Machines: A Comparative Analysis

The landscape of VMC milling machines for 2026 reveals intriguing insights. According to recent industry reports, precision machining is increasingly critical, with the global market expected to grow by 7.6% through 2028. This growth drives innovation, pushing manufacturers to enhance the accuracy and speed of their machines.

VMC machines are equipped with advanced features like high-speed spindles and multi-axis capabilities, yet not all machines meet the rigorous expectations. A comparative analysis of various models shows a striking discrepancy in performance ratings. For example, while some machines boast a precision tolerance of up to ±0.005 mm, others fall short, averaging around ±0.02 mm. These variations raise questions about reliability and the long-term viability of such equipment in demanding environments.

Additionally, the integration of IoT technology seems promising but is often inconsistently implemented. Many machines lack sufficient data analytics, limiting potential efficiency gains. Users report feeling overwhelmed by complex software interfaces, which can detract from productivity. As the demand for precision increases, the industry must critically evaluate these shortcomings to foster better solutions. It's a complex landscape filled with opportunities and challenges that need addressing.

2026 Best VMC Milling Machines for Precision Machining

| Model | Max Speed (RPM) | Table Size (inches) | Feed Rate (IPM) | Spindle Power (HP) | Price (USD) |

|---|---|---|---|---|---|

| Model A | 10,000 | 40 x 20 | 800 | 15 | $60,000 |

| Model B | 12,000 | 50 x 25 | 1000 | 20 | $75,000 |

| Model C | 15,000 | 45 x 22 | 1200 | 25 | $90,000 |

| Model D | 18,000 | 60 x 30 | 1500 | 30 | $100,000 |

User Reviews and Feedback on Leading VMC Milling Machines

User reviews and feedback play a crucial role in selecting VMC milling machines. Many users highlight accuracy as a key factor in their evaluations. A recent industry report indicated that 70% of machinists prioritize precision above all else. Without high accuracy, even the best-designed machines can underperform. The nuances of machining can sometimes lead to unexpected issues, causing delays and frustration.

Feedback also reveals trends in reliability and user experience. Over 60% of users have reported regular maintenance challenges. Some machines may require frequent adjustments, impacting overall productivity. Users often express a desire for improved documentation and support. Solid customer service can make a significant difference in addressing these concerns. An analysis of reviews suggests that clear instructions can boost user confidence and efficiency.

Moreover, while many machines boast advanced features, user frustrations often arise when the technology does not match expectations. There's a gap between technical specifications and real-world application. Feedback suggests a need for clearer communication regarding capabilities. This disconnect can lead to dissatisfaction. Both current users and potential buyers must consider these aspects when choosing their next investment.

Future Trends in VMC Milling Technology and Their Implications

The landscape of VMC milling technology is evolving rapidly. Recent market reports indicate that the global CNC milling machine market is expected to reach $100 billion by 2026. This growth reflects the increasing demand for precision machining in various industries, notably aerospace and automotive. Companies are focusing on automation and smart technology to enhance productivity.

Emerging trends highlight the integration of AI and IoT in milling machines. These technologies allow for real-time monitoring and improved predictive maintenance. Data suggests that equipment downtime can be reduced by up to 40% through advanced analytics. However, not all manufacturers are ready to adapt. The gap in technology adoption could widen. Consequently, companies lagging in digital transformation risk falling behind competitors.

Another significant trend is the push for sustainability in machining processes. Eco-friendly materials and energy-efficient machinery are becoming essential. Research shows that businesses adopting sustainable practices can save up to 30% on operational costs over time. Yet, many firms struggle to implement these changes effectively. The challenge lies in balancing innovation with cost control, which can hinder progress in this crucial area.

2026 Best VMC Milling Machines for Precision Machining

This chart illustrates the key performance metrics of some of the best VMC milling machines expected in 2026, showcasing their accuracy, speed, load capacity, and flexibility in precision machining operations.

Related Posts

-

Unveiling the Specifications: The Ultimate Guide to the Best CNC Lathe Machine for Global Buyers

-

Exploring CNC Milling Machine Innovations at the 2025 China Import and Export Fair

-

How to Choose Between CNC Lathe and Milling Machine?

-

Top Benefits of Using Precision CNC Milling Machines in Modern Manufacturing

-

2025 Top CNC Metal Milling Machines: Boosting Precision with 98% Efficiency

-

Top 7 CNC Lathe and Milling Machines for Precision Engineering in 2023