2025 Top CNC Metal Milling Machines: Boosting Precision with 98% Efficiency

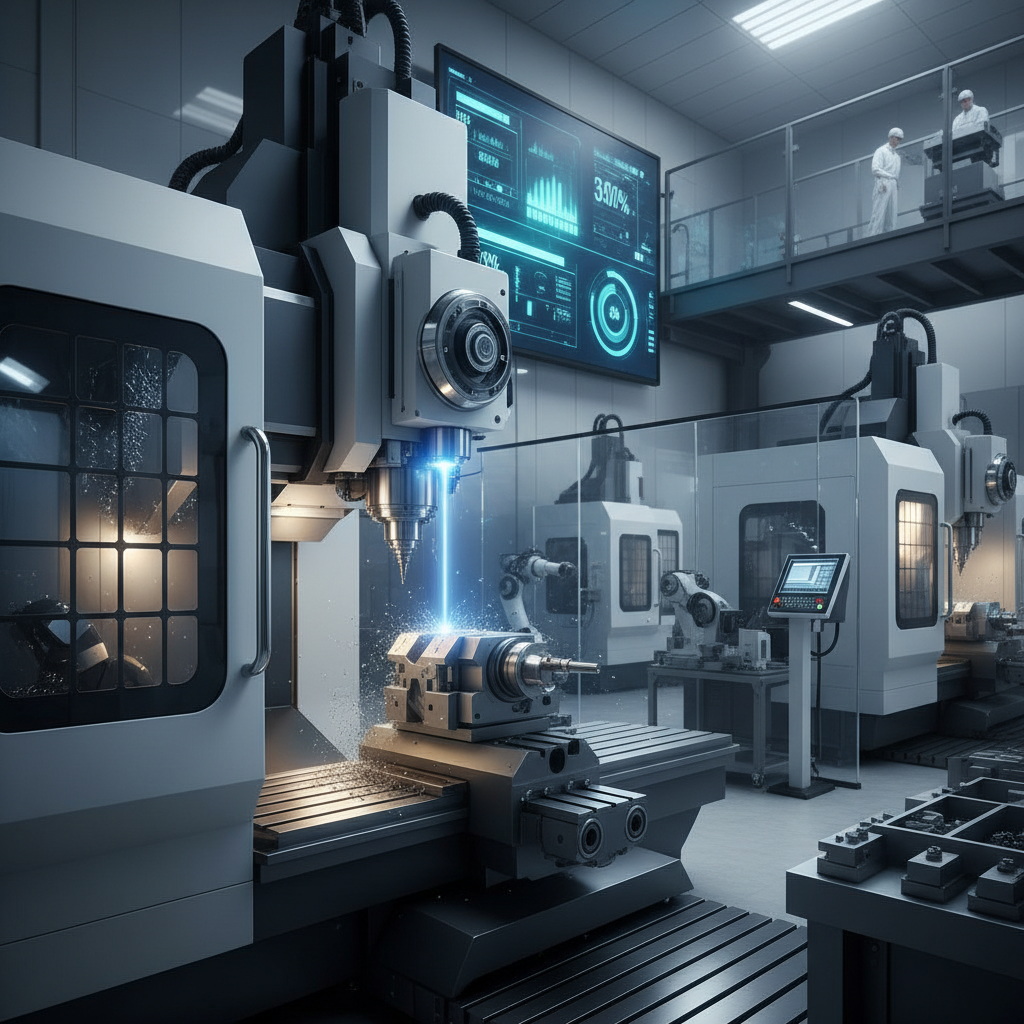

In the ever-evolving landscape of manufacturing, the importance of precision has never been more critical. As industries strive for efficiency and accuracy, the emergence of advanced technologies like CNC metal milling machines has revolutionized production processes. According to Dr. James Thompson, a renowned expert in CNC technology, "With the right CNC metal milling machine, companies can achieve up to 98% efficiency, transforming their production lines into models of precision and speed."

This statement underscores the significance of selecting the proper machinery in today's competitive environment. The 2025 Top CNC Metal Milling Machines not only promise remarkable efficiency but also embody breakthroughs that enhance precision in metalworking. As manufacturers increasingly turn to automation and advanced CNC solutions, understanding these developments becomes essential for making informed decisions in equipment acquisition and operational strategy.

By exploring the latest innovations and features in CNC metal milling machines, this overview aims to highlight key advancements that are shaping the future of manufacturing. With insights from industry leaders and the latest technological trends, businesses can better position themselves for success in an increasingly precise and efficient production landscape.

Top Features to Look for in CNC Metal Milling Machines in 2025

In 2025, selecting the right CNC metal milling machine is critical for achieving high precision and efficiency in production. The global market divides into two primary types: CNC 2D milling machines and CNC 3D milling machines. CNC 2D milling machines operate on two axes (X and Y), making them ideal for high-precision cutting and engraving of flat materials. These machines excel in creating signs, panels, and other intricate designs, ensuring top-notch quality in every detail.

In contrast, CNC 3D milling machines extend capabilities into three dimensions, allowing for more complex shapes and contours. When choosing a machine, essential features to consider include the precision of the axis movements, the type of control system, and the software compatibility for design inputs. Additionally, the efficiency of the machine, reflected in its operational speed and energy consumption, plays a significant role in enhancing overall productivity. As technology continues to advance, these machines are increasingly equipped with automated functions that further boost operational efficiency, making them indispensable tools in modern manufacturing environments.

Innovative Technologies Driving 98% Efficiency in Metal Milling

Innovative technologies are reshaping the landscape of metal milling, driving efficiency levels to an astonishing 98%. One notable advancement stems from the focus on sustainable practices alongside machining innovations. As the steel industry embraces new methods, such as enhanced machining techniques and smarter welding processes, significant strides in both productivity and environmental sustainability are achieved. The recent recognition of a startup for its pioneering milling technology exemplifies this trend, showcasing how modern solutions can revolutionize traditional manufacturing approaches.

Furthermore, the integration of Industry 4.0 principles within steel processing facilities is vital for elevating operational efficiency. Initiatives that equip the workforce with advanced technological expertise are crucial in maximizing the effectiveness of CNC machines. These innovations not only streamline manufacturing processes but also pave the way for a greener footprint in the industry by reducing energy consumption and waste. As companies increasingly prioritize technological investments, the future of CNC metal milling looks promising, with enhanced precision at the forefront of the industry's evolution.

Comparative Analysis of the Top 5 CNC Metal Milling Machines of 2025

The CNC metal milling machine market is experiencing significant growth, driven by advancements in technology and increasing demand for precision manufacturing. A comparative analysis of the top five CNC metal milling machines for 2025 reveals key innovations that boost efficiency and accuracy. With operation efficiencies reaching up to 98%, these machines are designed to meet the rigorous demands of modern manufacturing environments, providing manufacturers with the tools needed for superior performance.

As the global CNC machine market is projected to expand from $101.22 billion in 2025 to $195.59 billion by 2032, understanding the leading players in the CNC metal milling industry becomes crucial. The top five machines not only enhance production capabilities but also integrate smart technology to optimize the milling process, reduce waste, and improve energy efficiency. With meticulous attention to functionality and user experience, these machines stand out in a competitive landscape, indicating a shift towards more automated and precise machining solutions in the coming years.

Customer Reviews and Success Stories: Real-World Impact of CNC Milling

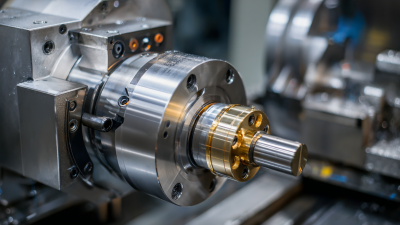

Customer reviews and success stories provide invaluable insights into the real-world impact of CNC metal milling machines. Users consistently highlight the precision and reliability that these machines bring to their production processes.

One notable review from a mid-sized automotive parts manufacturer emphasizes how their new CNC milling machine improved not only the accuracy of their components but also reduced waste material by nearly 20%. This efficiency boost has made a significant difference in their bottom line, allowing them to allocate resources more effectively and invest in further technological advancements.

Another success story comes from a custom fabrication shop that specializes in intricate designs. They report that the 98% efficiency of their CNC milling machine enabled them to take on more complex projects without sacrificing quality. Clients have praised both the speed and detail of the finished products, leading to an increase in repeat business and referrals. This has transformed their operational capabilities, allowing them to expand their service offerings while maintaining high standards and customer satisfaction. These real-world examples underscore the transformative power of advanced CNC milling technology in diverse industries.

Future Trends in CNC Milling Technology: What to Expect Beyond 2025

As we look beyond 2025, the landscape of CNC milling technology is primed for revolutionary changes that will enhance precision and efficiency. With continuous advancements in software and machine design, manufacturers can anticipate increased integration of artificial intelligence and machine learning. This evolution will enable real-time adjustments during the milling process, significantly reducing waste and ensuring the highest quality products.

Tips for manufacturers: Investing in training for your workforce can pay significant dividends. Equip your team with the skills to operate new smart CNC machines and interpret data acquired from advanced sensors. This will not only maximize the benefits of new technology but also foster a culture of innovation within your organization.

Furthermore, sustainability will become a central theme in future CNC milling operations. Embracing eco-friendly materials and energy-efficient machines will not only comply with regulations but also appeal to environmentally conscious consumers. By adapting to these trends early, companies can secure a competitive edge in a rapidly evolving market.

Tips for staying ahead: Keep an eye on emerging industry standards and technological advancements. Regularly updating your machinery and processes can position your business as a leader in precision CNC milling.

Related Posts

-

Top 10 CNC Milling Machines for Precision Manufacturing in 2023

-

Unveiling the Specifications: The Ultimate Guide to the Best CNC Lathe Machine for Global Buyers

-

Top Strategies for Choosing the Best CNC Milling Machine for Your Business Needs

-

Unlocking Innovation with the Best CNC Machine Milling Machine Options for Global Buyers

-

Discover How Top Chinese Factories Redefine Excellence in Precision CNC Milling Machines

-

China's Best Precision CNC Milling Machines Deliver Global Quality You Can Trust